Preparation method of UV (ultraviolet) curing polythiophene derivative conductive polymer material

A technology of polythiophene derivatives and conductive polymers, which is applied in organic chemistry and other fields, can solve the problems of low fluorescence quantum efficiency, and achieve the effects of clear structure characterization, mild process conditions, and less reversible reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

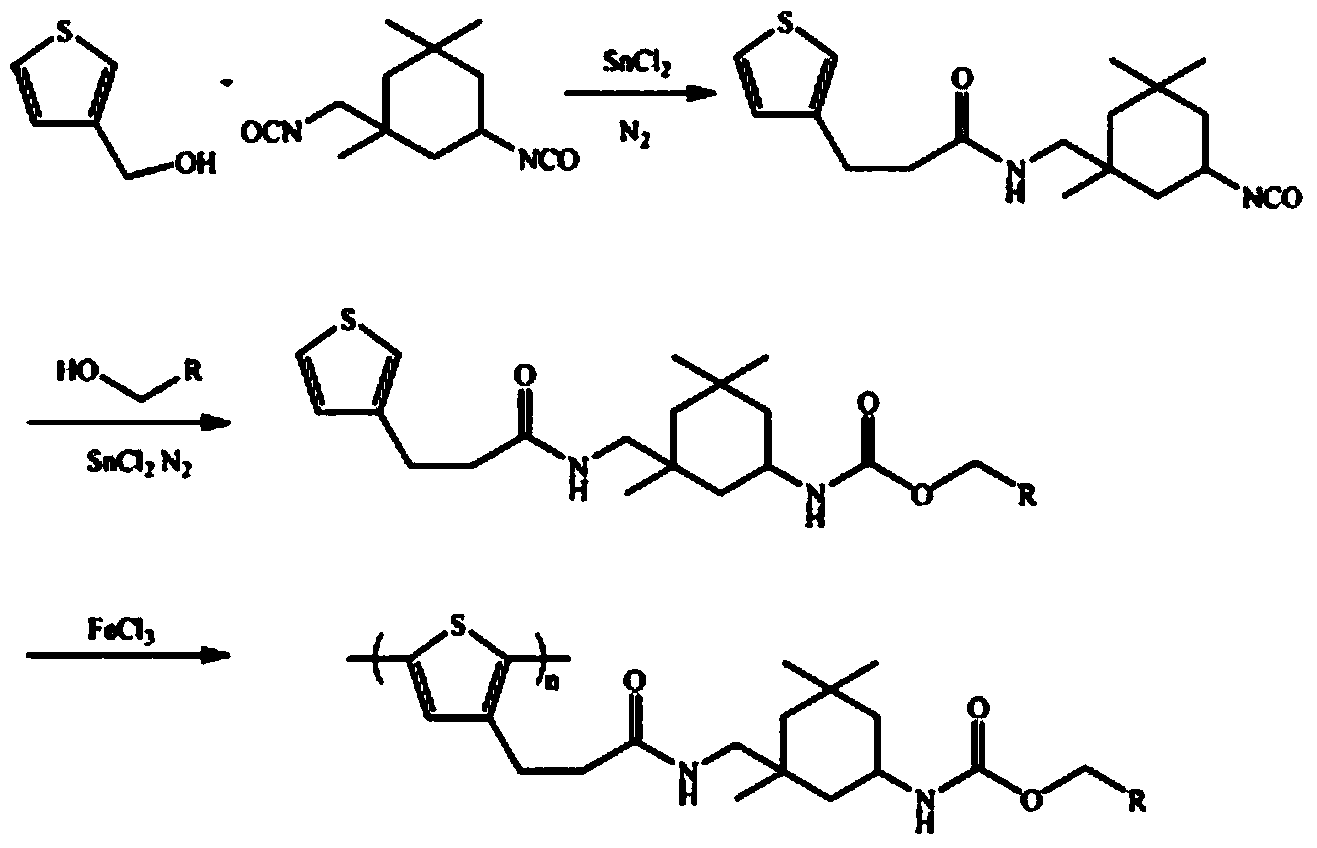

[0025] A method for preparing an ultraviolet light-curable polythiophene derivative conductive polymer material, the steps are:

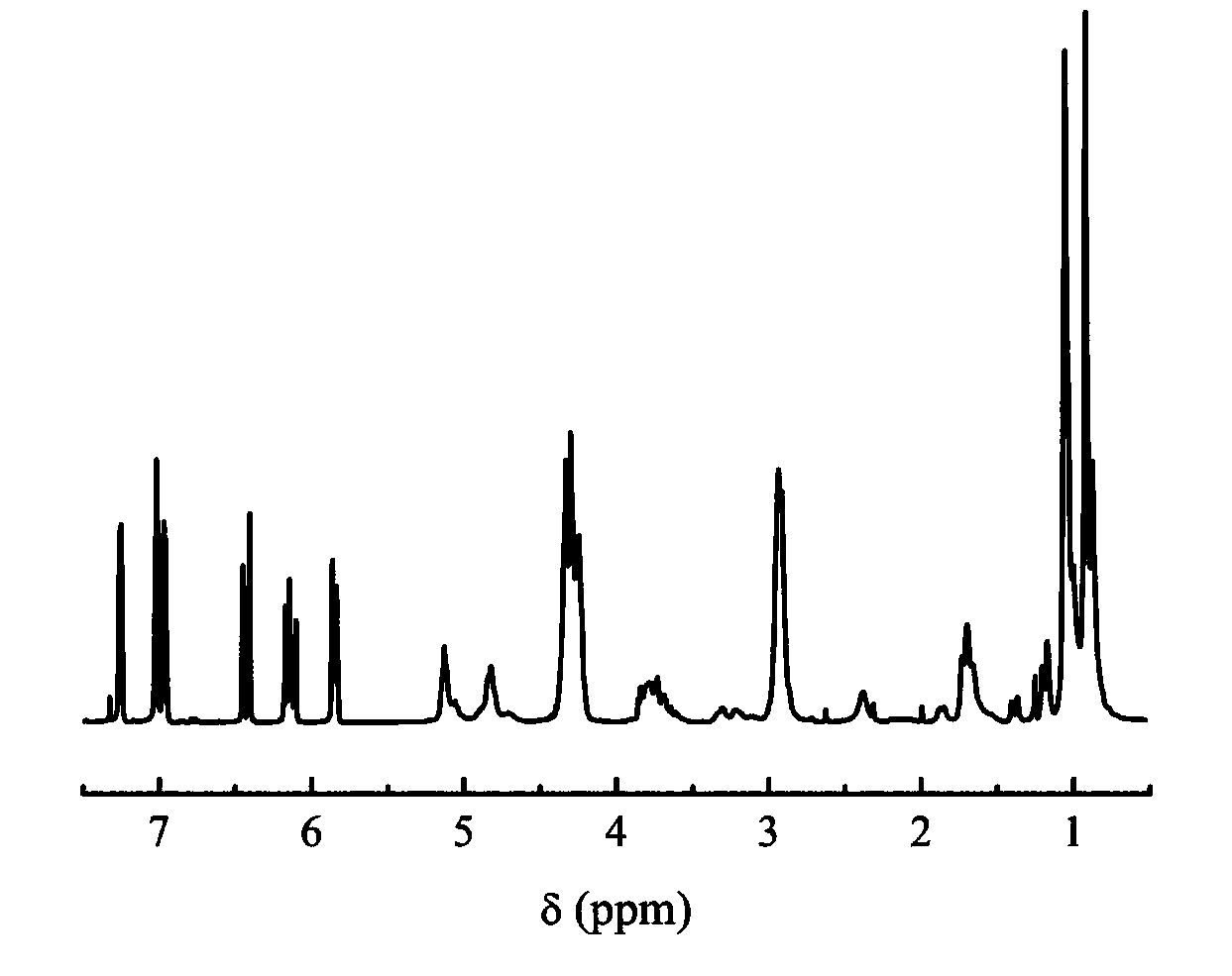

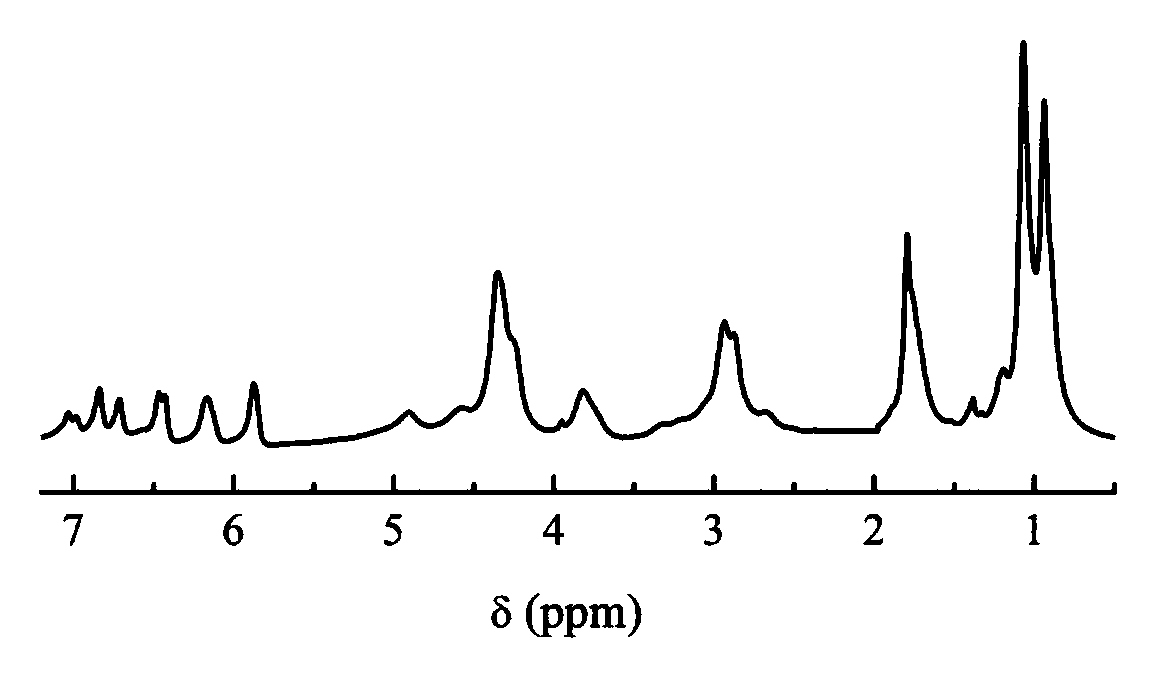

[0026] (1) Preparation of thiophene derivative monomer: Add 0.12mol of isophorone diisocyanate, 80mL of dioxane and 0.06% by weight of reactant to a 250mL three-neck flask under nitrogen atmosphere. For stannous, 0.12mol of 3-thiophene ethanol was dissolved in 40mL of dioxane and slowly added dropwise at a rate of 12 drops / minute to the three-necked bottle. ℃, reacted for 4 hours; then continue to add 0.12 mol of hydroxyethyl acrylate dissolved in 20 mL of dioxane and p-hydroxyanisole accounting for 0.3% of the double bond moles of the reactant in the dropping funnel, and add 20 drops / Add it dropwise into a three-necked flask at a speed of 1 minute, raise the temperature to 70° C., continue the reaction for 8 hours, and distill off the solvent under reduced pressure to obtain about 0.12 mol of a thiophene derivative monomer with an acrylic acid dou...

Embodiment 2

[0032] A method for preparing an ultraviolet light-curable polythiophene derivative conductive polymer material, the steps are:

[0033] (1) Preparation of thiophene derivative monomer: Add 0.10mol of isophorone diisocyanate, 60mL of toluene and 0.06% of the reactant weight to a 250ml three-necked flask under ice-water bath conditions and a nitrogen atmosphere. For stannous, dissolve 0.10 mol of 3-thiophene methanol in 30 mL of toluene and slowly drop it into the three-neck flask at a rate of 10 drops / minute. After the drop is completed, continue to react in an ice bath for 2 hours, and then heat up to 55 ° C. React for 4 hours; then continue to add 0.10 mol of hydroxyethyl methacrylate dissolved in 15 mL of toluene and p-hydroxyanisole accounting for 0.5% of the double bond moles of the reactant in the dropping funnel, and add 25 drops / min Add it dropwise into a three-necked flask at a high speed, raise the temperature to 70°C, continue the reaction for 10 hours, and distill of...

Embodiment 3

[0036] A method for preparing an ultraviolet light-curable polythiophene derivative conductive polymer material, the steps are:

[0037] (1) Preparation of thiophene derivative monomers: Add 0.11mol of toluene diisocyanate, 70mL of ethyl acetate and 0.09% of dibutyl diisocyanate by weight of reactants to a 250ml three-necked flask under ice-water bath conditions and nitrogen atmosphere. For tin laurate, dissolve 0.11mol of 3-thiophene methanol in 35mL of ethyl acetate and slowly add it dropwise to the three-necked bottle at a rate of 10 drops / min. 60 o C, reacted for 3 hours; then continue to add 0.11mol 7-hydroxyl-4-methylcoumarin dissolved in 20mL ethyl acetate in the dropping funnel, and drop in the three-necked flask at a speed of 20 drops / minute, The temperature was raised to 70° C., the reaction was continued for 10 hours, and the solvent was distilled off under reduced pressure to obtain about 0.11 mol of a thiophene derivative monomer with a coumarin group.

[0038]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com