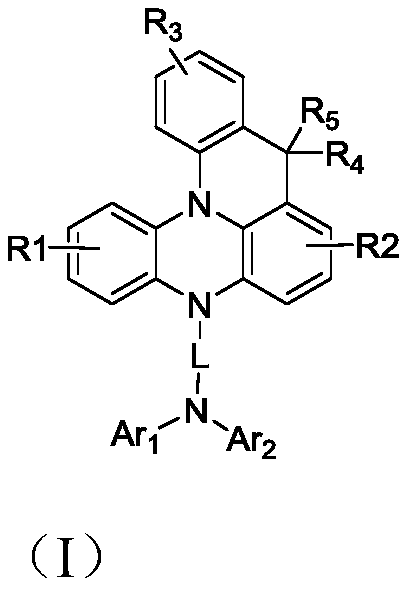

Organic electroluminescent compound and preparation method thereof and organic electroluminescent device

A compound and luminescent technology, applied in organic chemistry, electrical solid devices, electrical components, etc., can solve the problems of low lifespan, complex synthesis process, time-consuming, etc., achieve good thermal stability, simple preparation route, and excellent performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

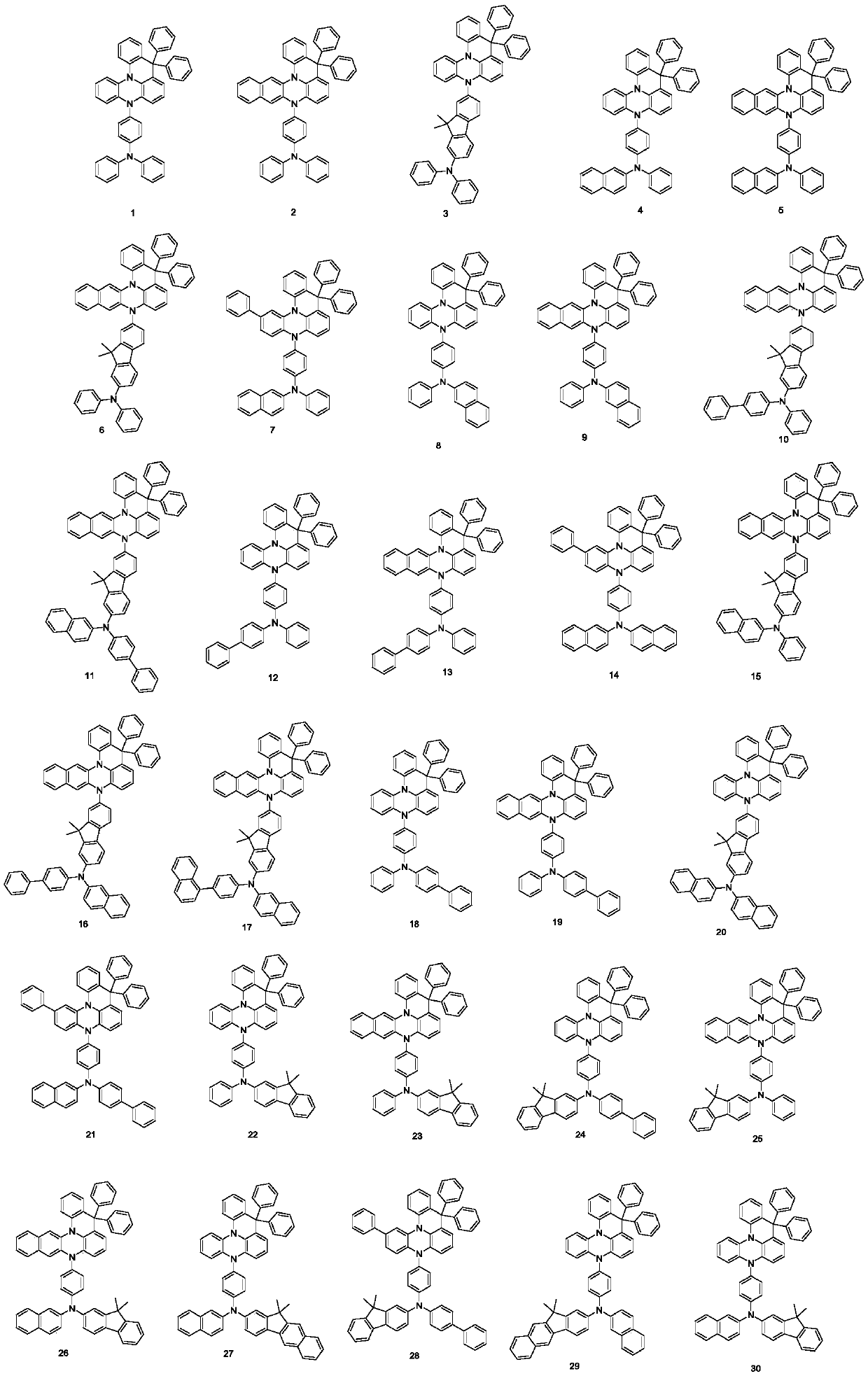

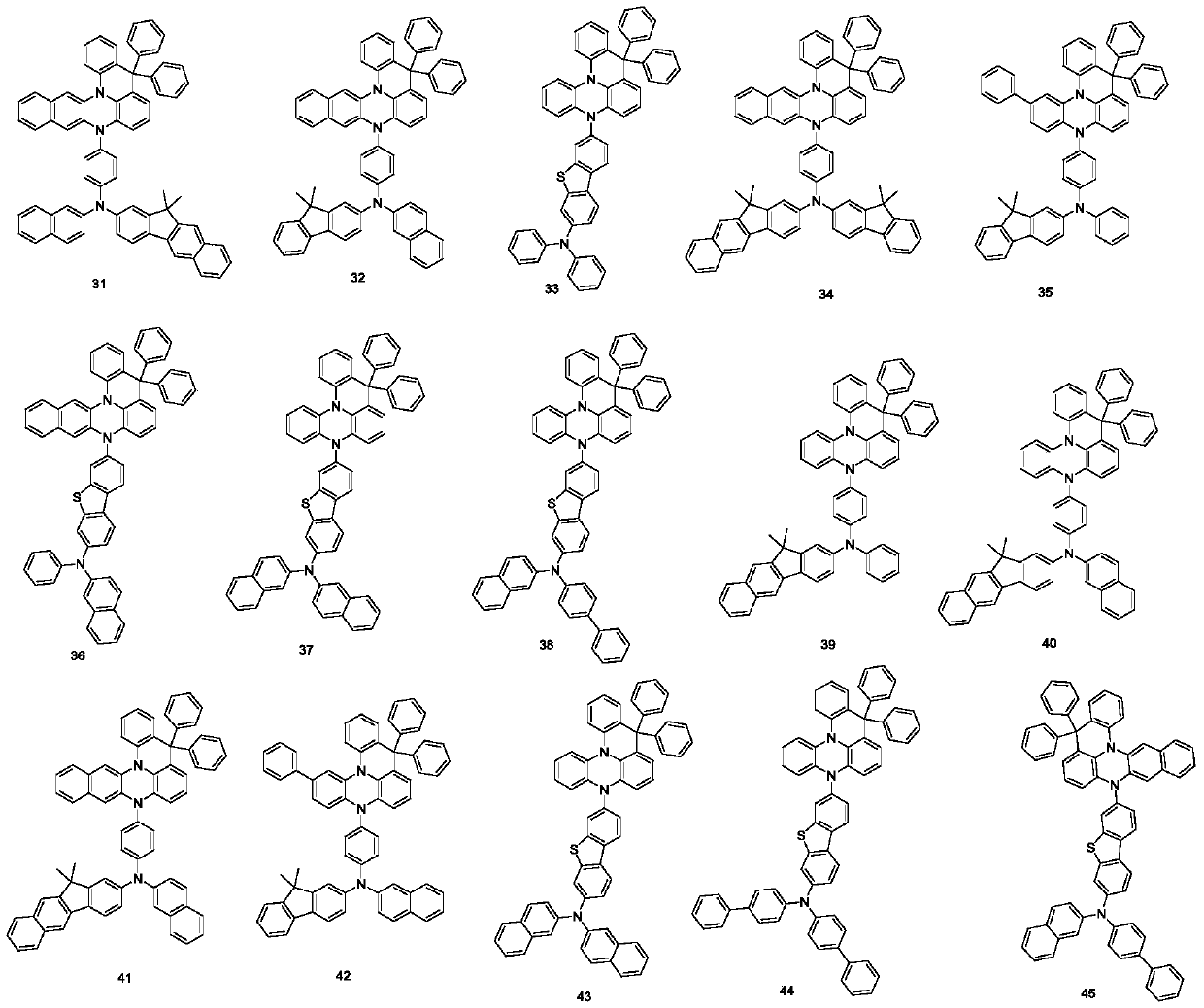

Embodiment 1

[0030]

[0031] Add reactant 1-1 (50mmol) and reactant 1-2 (55mmol), (100mmol) sodium tert-butoxide, 1mmol bis-palladium, into 150ml toluene, raise the temperature to 110°C under nitrogen protection and stir for 12 hours. After the reaction was completed, it was washed with water at room temperature, separated, the organic phase was concentrated, precipitated with petroleum ether, and filtered to obtain intermediate 1-3 (18.2 g, yield 80%, MW: 454.47).

[0032] The intermediates shown in Table 1 below can be synthesized according to the method for synthesizing intermediates 1-3 above.

[0033] Table 1 Example 1 reaction raw materials and product structure and characterization summary

[0034]

[0035]

Embodiment 2

[0037]

[0038] Add 40mmol of intermediate 1-3 into 160mL of triethyl phosphite, raise the temperature to 120°C and stir for 6h. After the reaction was completed, water was slowly added at room temperature, the solid was precipitated by stirring, and dried by filtration to obtain intermediate 1-4 (12.8 g, yield 76%, MW: 422.94).

[0039] The intermediates shown in Table 2 below can be synthesized according to the method for synthesizing intermediates 1-4, but not limited to the following intermediates.

[0040] Table 2 Example 2 reaction raw materials and product structure and characterization summary

[0041]

[0042]

Embodiment 3

[0044]

[0045] Dissolve intermediate 1-4 (30mmol) in toluene, add reactant 1-5 (33mmol), add Pd under nitrogen protection 2 (dba) 3 (0.3mmol), tri-tert-butylphosphine (3mmol), sodium tert-butoxide (90mmol), heated to reflux and stirred for 12 hours. After the reaction was completed, add water to wash at room temperature, separate and concentrate the product solution, precipitate with petroleum ether, and filter to obtain intermediate 1-6 (13.3 g, yield: 77%, MW: 576.85).

[0046] The intermediates shown in Table 3 below can be synthesized according to the method for synthesizing intermediates 1-6.

[0047] Table 3 Example 3 reaction raw materials and product structure and characterization summary

[0048]

[0049]

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com