Hierarchical porous carbon block material for formaldehyde purification and preparation method and application thereof

A formaldehyde purification and hierarchical pore technology, applied in the field of materials, can solve the problems that hinder the performance improvement and application expansion of porous carbon materials, unfriendly environment, complicated process, etc., and achieve efficient pore structure control methods, simple recycling and processing, and simple preparation routes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

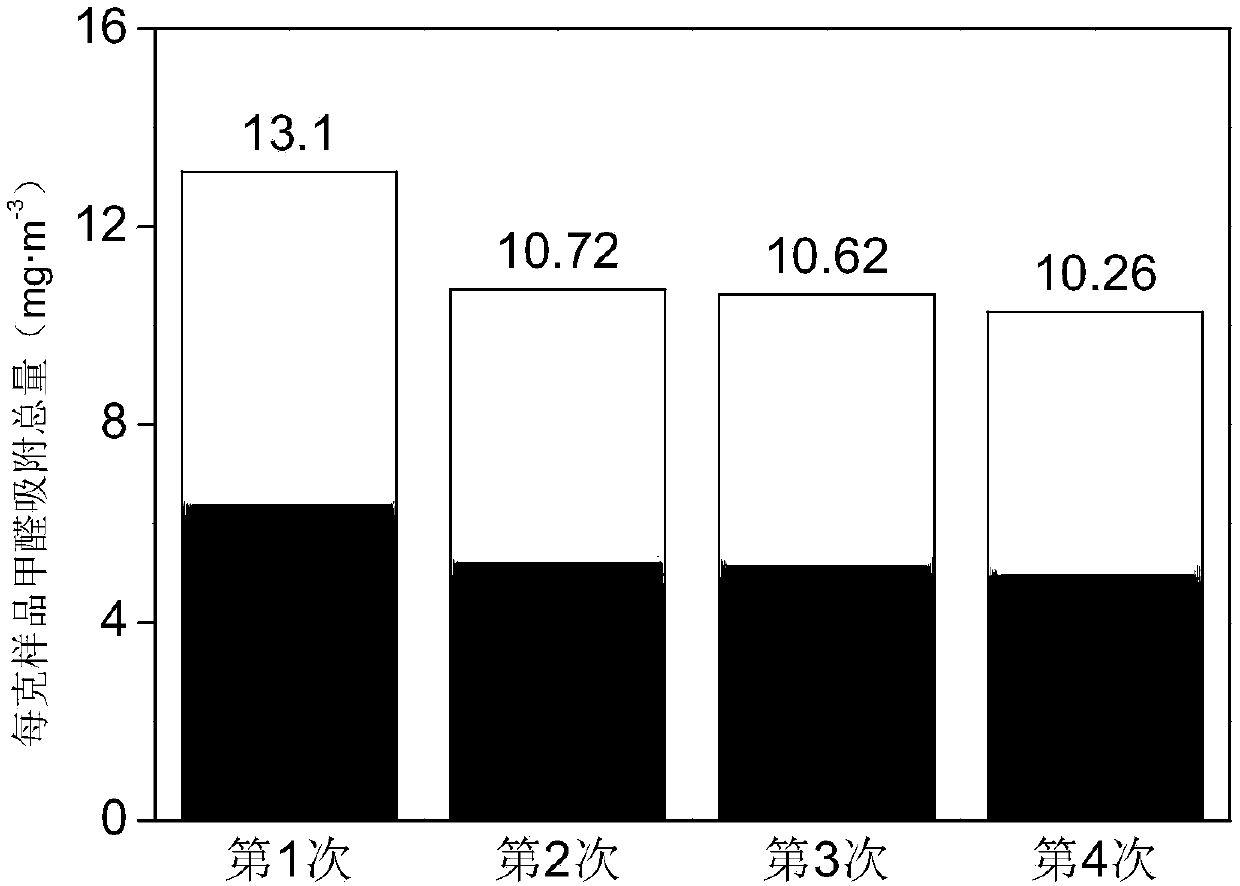

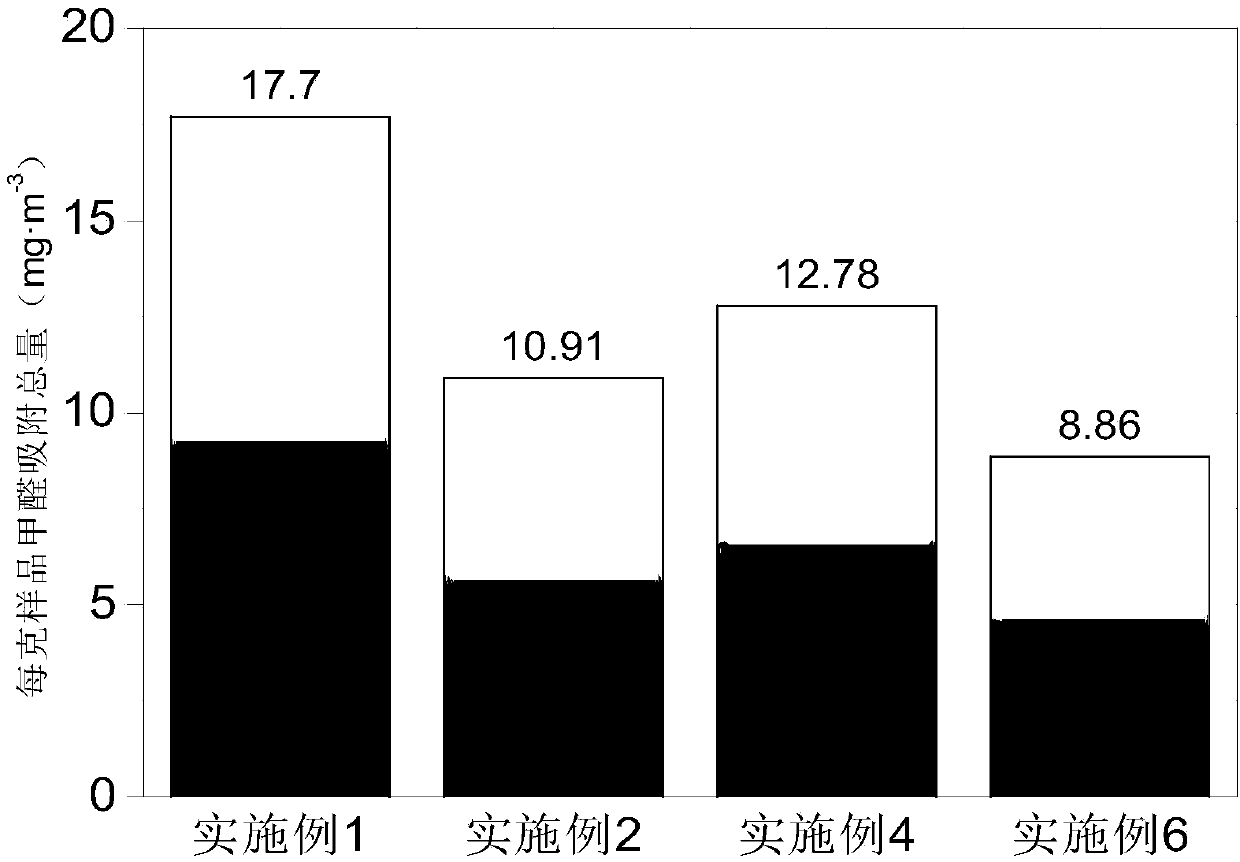

[0028] Example 1

[0029] A preparation method of hierarchical porous basswood-based carbon block material for formaldehyde purification, including the following steps:

[0030] (1) Dry the basswood to constant weight;

[0031] (2) Carbonize and activate the wood block in step (1): ①Under the protection of 300mL / min nitrogen, increase from room temperature to 900℃ at a rate of 5℃ / min, and keep it for 1.5h; ②Inlet flow 150mL / min CO 2 The gas is activated for 2h; ③Stop the introduction of CO 2 The gas is continuously blown with nitrogen and cooled to room temperature to obtain a layered pore linden wood-based carbon block material for formaldehyde purification.

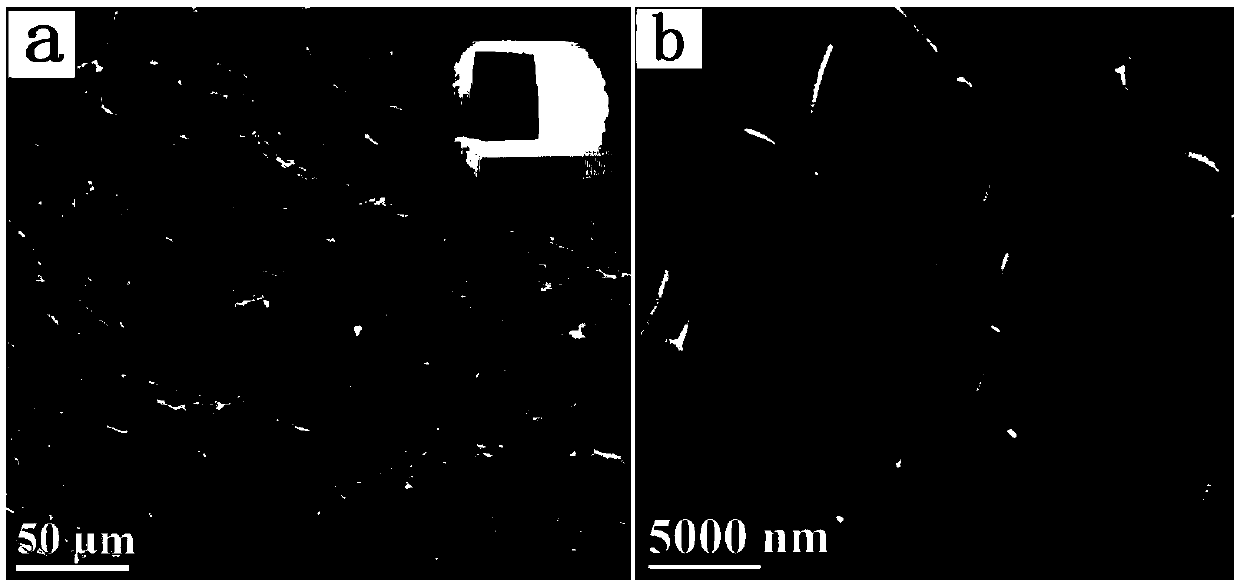

[0032] The BET specific surface area of the hierarchical porous basswood-based carbon block material prepared for formaldehyde purification was tested by the ASAP2020 adsorber nitrogen adsorption method produced by Micromeritics, USA 2 / g, Langmuir specific surface area is 1591m 2 / g; pore volume is 1.06cm 3 / g. Scanning ele...

Example Embodiment

[0034] Example 2

[0035] A preparation method of hierarchical porous basswood-based carbon block material for formaldehyde purification, including the following steps:

[0036] (1) Dry the basswood to constant weight;

[0037] (2) Carbonize and activate the wood block in step (1): ①Under the protection of 300mL / min nitrogen, increase from room temperature to 900℃ at a rate of 5℃ / min, and keep it for 1.5h; ②Inlet flow 150mL / min CO 2 Gas activation for 0.5h; ③Stop CO 2 The gas is continuously blown with nitrogen and cooled to room temperature to obtain a layered pore linden wood-based carbon block material for formaldehyde purification.

[0038] The BET specific surface area of the hierarchical porous linden wood-based carbon block material prepared for formaldehyde purification was tested with the nitrogen adsorption method of the ASAP2020 adsorber produced by the American Micromeritics company. The BET specific surface area was 991m. 2 / g, Langmuir specific surface area is 1364m 2 ...

Example Embodiment

[0040] Example 3

[0041] A preparation method of hierarchical porous basswood-based carbon block material for formaldehyde purification, including the following steps:

[0042] (1) Dry the basswood to constant weight;

[0043] (2) Carbonize and activate the wood block in step (1): ①Under the protection of 300mL / min nitrogen, increase from room temperature to 900℃ at a rate of 5℃ / min, and keep it for 1.5h; ②Inlet flow 150mL / min CO 2 The gas is activated for 1h; ③Stop the introduction of CO 2 The gas is continuously blown with nitrogen and cooled to room temperature to obtain a layered pore linden wood-based carbon block material for formaldehyde purification.

[0044] The BET specific surface area of the hierarchical porous linden wood-based carbon block material prepared for formaldehyde purification was tested by the ASAP2020 adsorber nitrogen adsorption method produced by the American Micromeritics Company, which was 919m. 2 / g, Langmuir specific surface area is 1268m 2 / g; pore ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com