Calcined anionic clay visible-light catalyst and preparation method and purposes thereof

An anionic clay, visible light technology, used in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as long degradation time, achieve short degradation time and cost The effect of low cost and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

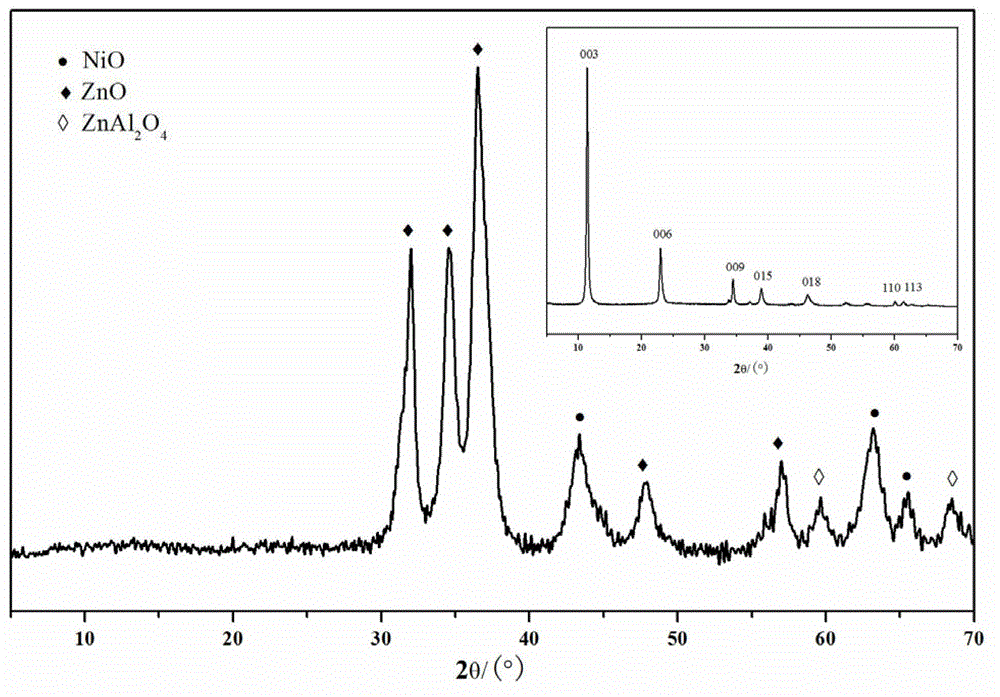

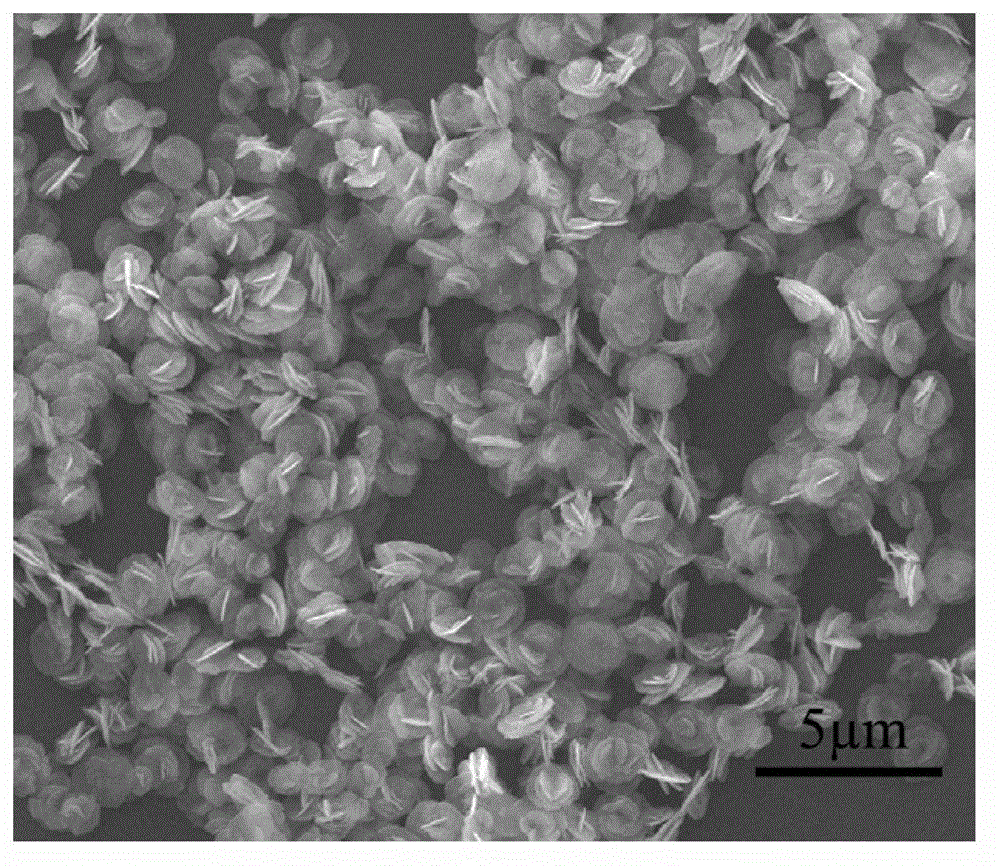

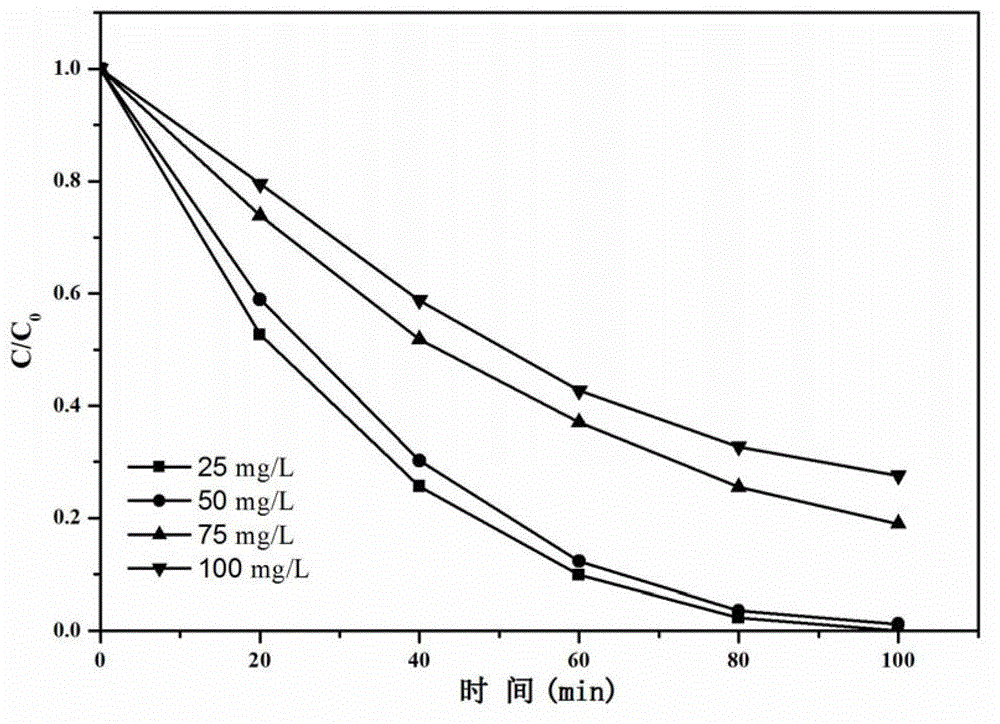

[0031] NiZnAl-2 type calcined anionic clay visible light catalyst, prepared by the following steps:

[0032] (1) Weigh 0.02mol (5.82g) Ni(NO 3 ) 2 ·6H 2 O, 0.04mol (11.90g) Zn (NO 3 ) 2 ·6H 2 O and 0.02mol (7.50g) Al(NO 3 ) 3 Mixed, in the mixture (Ni 2+ +Zn 2+ ) and Al 3+ The molar ratio is equal to 3, Zn 2+ with you 2+ The mole of is equal to 2;

[0033] Prepare 3 parts of the above mixture, labeled as samples A, B, C respectively. Then weigh CO(NH 2 ) 2 0.2mol (12.01g), 0.5mol (30.03g), 0.6mol (36.04g) were added to samples A, B, and C. CO(NH 2 ) 2 with Al 3+ The molar ratio of is equal to 10, CO(NH 2 ) 2 with Al 3+ The molar ratio of is equal to 25, CO(NH 2 ) 2 with Al 3+ The molar ratio is equal to 30.

[0034] Samples A, B, and C were placed in three 500mL beakers, respectively, and 250mL of deionized water were added, and the beakers were placed in a 50kHz ultrasonic scrubber for 10 minutes to obtain a clear mixed solution.

[0035] (2) The mix...

Embodiment 2

[0038] NiZnAl-3 calcined anionic clay visible light catalyst, prepared by the following steps:

[0039] (1) Weigh 0.015mol (4.36g) Ni(NO 3 ) 2 ·6H 2 O, 0.045mol (13.39g) Zn (NO 3 ) 2 ·6H 2 O, 0.02mol (7.50g) Al(NO 3 ) 3 , 0.5mol (30.03g) CO (NH 2 ) 2 , where (Ni 2+ +Zn 2+ ) and Al 3+ The molar ratio is equal to 3, Zn 2+ with you 2+ The mole is equal to 3, CO(NH 2 ) 2 with Al 3+The molar ratio is equal to 25, put the weighed reagent in a 500mL beaker, add 250mL deionized water, place the beaker in a 50kHz ultrasonic scrubber for 10min, and obtain a clear mixed solution.

[0040] (2) Transfer the mixed solution into a 500mL three-neck flask, heat hydrolysis at 100°C, and reflux for aging for 48 hours. The turbid solution is naturally cooled to room temperature for 2 hours. The measured pH value is 6.0, centrifuged at 4000rpm for 5 minutes, and the supernatant is removed to obtain NiZnAl The weakly acidic precipitation of layered double hydroxide, the obtained sa...

Embodiment 3

[0045] NiZnAl-4 type calcined anionic clay visible light catalyst, prepared by the following steps:

[0046] (1) Weigh 0.008mol (2.33g) Ni(NO 3 ) 2 ·6H 2 O, 0.032mol (9.52g) Zn (NO 3 ) 2 ·6H 2 O, 0.02mol (7.50g) Al(NO 3 ) 3 With 0.5mol (30.03g) CO (NH 2 ) 2 mixed, marked as sample A, where (Ni 2+ +Zn 2+ ) and Al 3+ The molar ratio of Zn is equal to 2, Zn 2+ with you 2+ The mole is equal to 4, CO (NH 2 ) 2 with Al 3+ The molar ratio of is equal to 25;

[0047] Weigh 0.012mol (3.49g) Ni(NO 3 ) 2 ·6H 2 O, 0.048mol (14.28g) Zn (NO 3 ) 2 ·6H 2 O, 0.02mol (7.50g) Al(NO 3 ) 3 With 0.5mol (30.03g) CO (NH 2 ) 2 mixed, marked as sample B, where (Ni 2+ +Zn 2+ ) and Al 3+ The molar ratio is equal to 3, Zn 2+ with you 2+ The mole is equal to 4, CO (NH 2 ) 2 with Al 3+ The molar ratio of is equal to 25;

[0048] Weigh 0.02mol (5.82g) Ni(NO 3 ) 2 ·6H 2 O, 0.08mol (23.80g) Zn (NO 3 ) 2 ·6H 2 O, 0.02mol (7.50g) Al(NO 3 ) 3 With 0.5mol (30.03g) CO (NH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com