Preparation method of carbon/carbon composite material with high heat conduction

A technology of carbon composite materials and high thermal conductivity, applied in the field of composite materials, can solve the problems of low material strength and difficulty in the application of high-temperature structural materials, and achieve the effect of large volume fraction, large thermal conductivity and small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

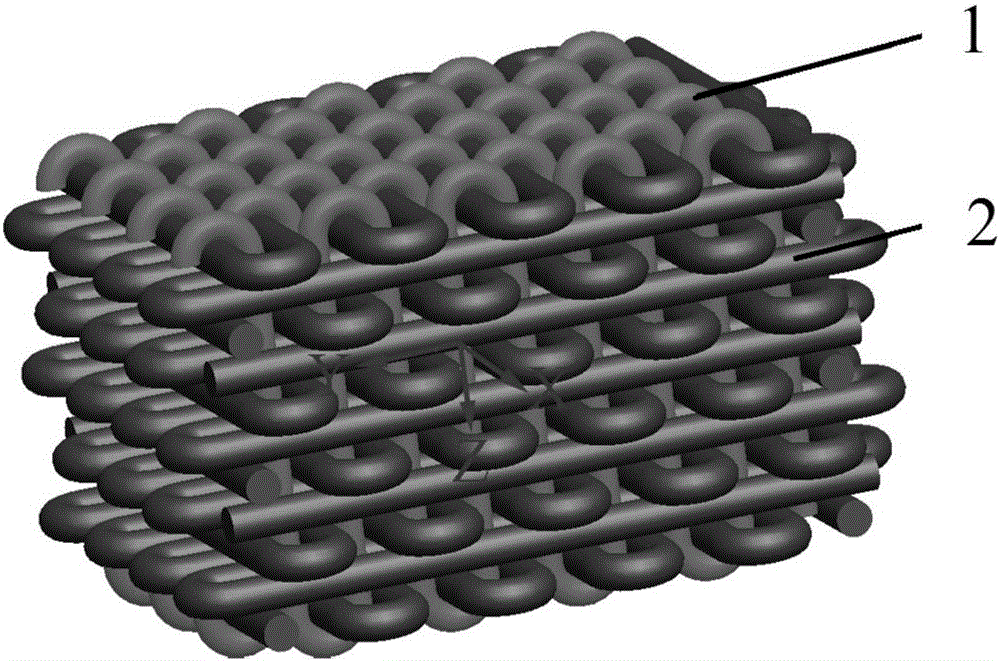

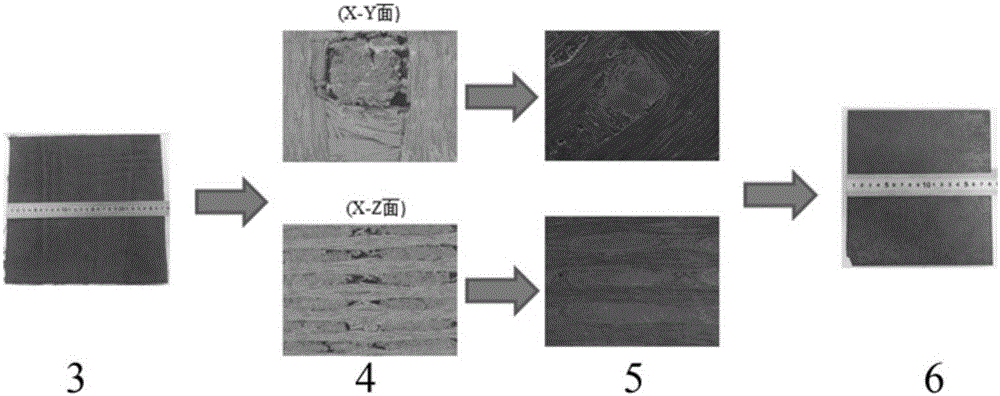

[0028] see figure 1 , select the mesophase pitch-based carbon fiber treated by low temperature carbonization at 400℃, and prepare two-dimensional orthogonal ply by winding yarn on the X-Y plane ( figure 1 2 places in the middle), and a 20 mm thick mesophase pitch-based carbon fiber cross-ply was prepared. Then the above-mentioned layup is placed between two plain weave PAN-based carbon cloths, and passed through the T-300PAN-based carbon fiber of 2K ( figure 1 Middle 1) to get the fiber preform by puncturing in the Z direction. Then carbonization treatment at 1100°C and graphitization treatment at 2800°C were carried out to obtain a three-dimensional orthogonal high thermal conductivity fiber preform ( figure 2 in 3 places). Densified to 1.53g / cm by multiple chemical vapor infiltration 3 ( figure 2 4 places in the middle); followed by mechanical processing to remove the PAN-based carbon cloth layer on the surface, followed by liquid-phase impregnation and pyrolytic dens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com