Metal lithium-framework carbon composite material and preparation method thereof, negative electrode and secondary battery

A carbon composite material, secondary battery technology, applied in secondary batteries, battery electrodes, non-aqueous electrolyte battery electrodes, etc. The effect of suppressing the formation of dendrites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

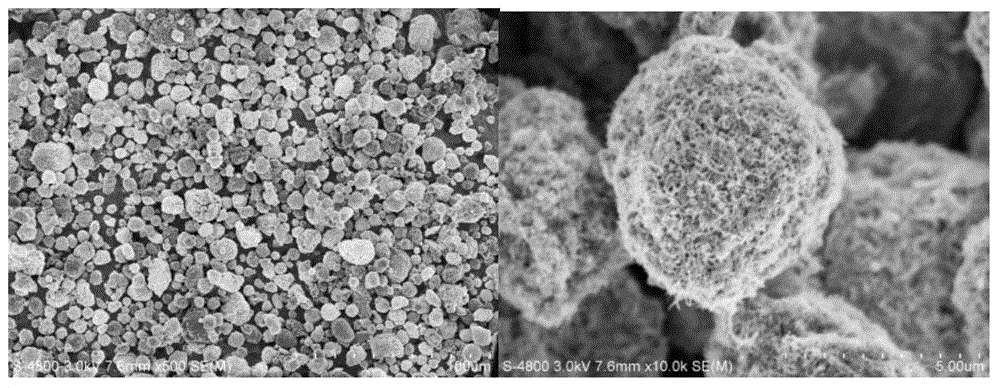

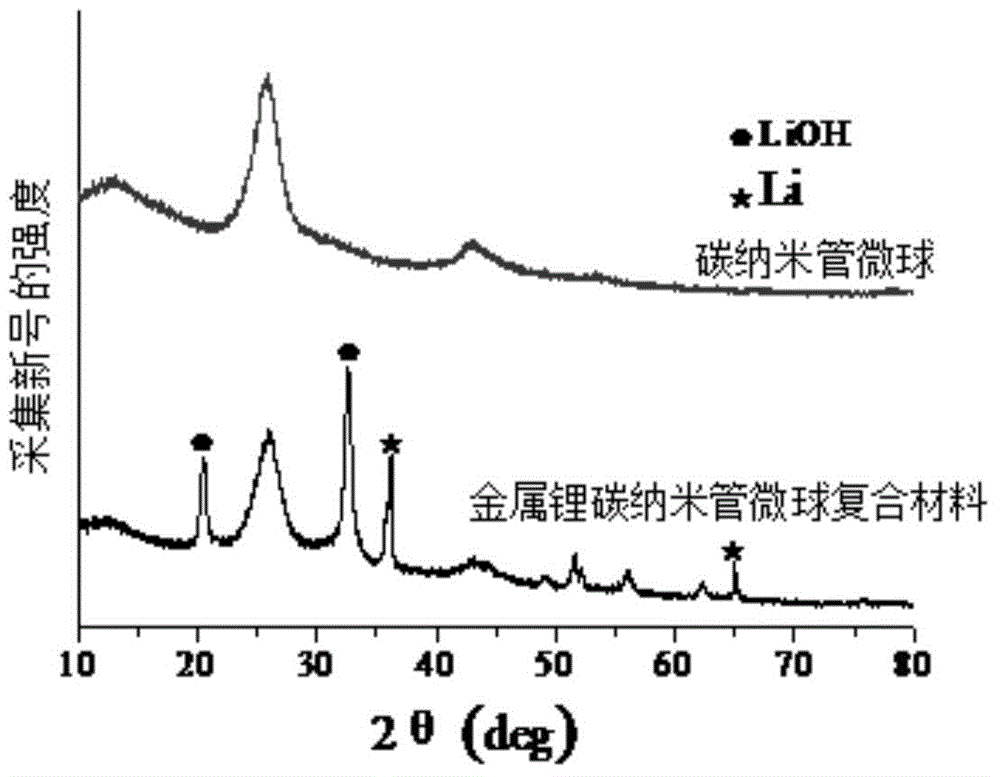

[0032] Another aspect of the embodiment of the present application provides a method for preparing carbon nanotube microspheres, comprising: at least uniformly dispersing carbon nanotubes in a solvent to form a surfactant-free dispersion and then spray-drying to obtain the carbon nanotube microspheres.

[0033] The shape of the carbon nanotube microsphere material can be powder or granular.

[0034]More specifically, as one of the feasible embodiments of the present invention, the preparation method may include: at least dispersing the carbon nanotubes in a solvent to obtain a dispersion without surfactant, and then inputting the dispersion into the mist of the spray dryer In the atomizer, and form tiny mist droplets, and make the mist droplets contact with the hot air flow in the spray dryer, so that the solvent in the liquid mist droplets evaporates rapidly, and then the The carbon nanotubes in the liquid mist are aggregated to form carbon nanotube microspheres, and then th...

Embodiment 1

[0058] First weigh 200mg of battery-grade lithium metal and 200mg of commercial porous carbon (average pore size 2.6nm) into a heater that is inert to lithium metal, heat to the melting temperature of lithium metal, stir vigorously, and continue for several minutes. During the mixing process, pores are found Carbon cannot be used as a carrier to absorb molten metal lithium, and the formed complex is in a block shape, indicating that the average pore size is too small to effectively absorb molten metal lithium.

Embodiment 2

[0060] First weigh 200mg of battery-grade lithium metal and 200mg of commercial acetylene black (average pore size 14.4nm) into a heater that is inert to lithium metal, heat to the melting temperature of lithium metal, stir vigorously for 6-8 minutes, and the mixing is over Afterwards, the temperature was lowered to room temperature, and the whole process was carried out in an argon atmosphere.

[0061] Metal lithium-acetylene black microspheres were obtained, wherein the metal lithium loading was 8.0%.

[0062] Use the material obtained above as the negative electrode of the lithium battery:

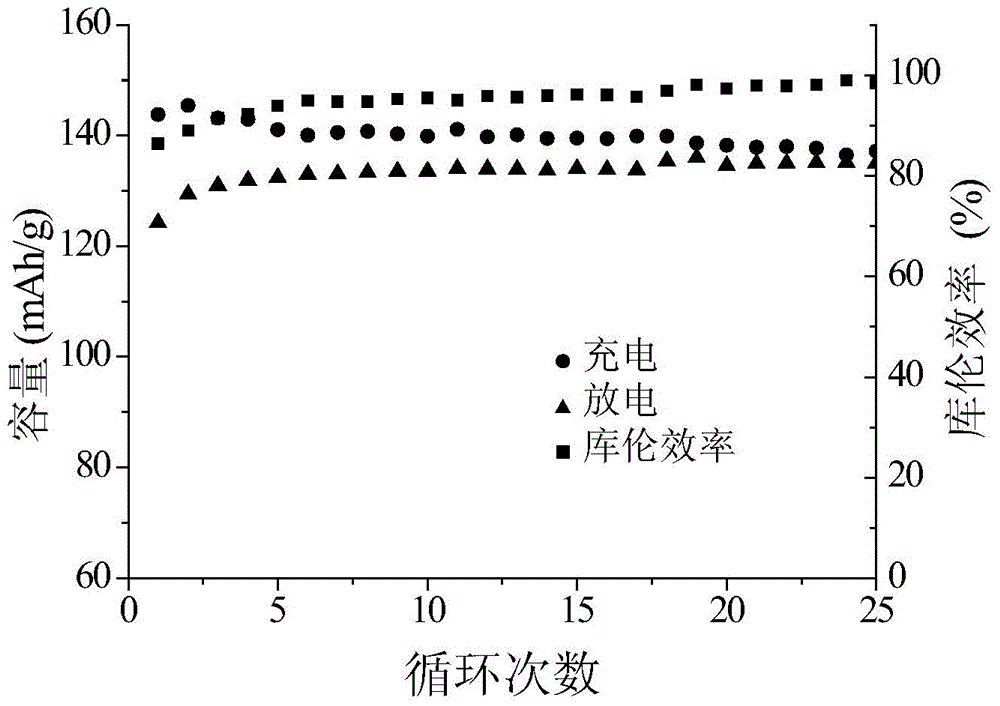

[0063] The cathode material of lithium ion battery is LiFePO 4 :PVFD:AB=88:5:7, the thickness is 150um, the electrolyte is 1mol / LLiPF 6 / EC-DMC (1:1vol), assembled into a button battery (CR2025), cycled 25 times, the coulombic efficiency of the battery was not high during the whole cycle, and the coulombic efficiency tended to be stable as the cycle progressed. figure 1 A schematic d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com