Graphene-ionic liquid composite material and preparation method thereof

An ionic liquid and composite material technology, applied in the field of graphene-ionic liquid composite materials and their preparation, can solve the problems of reducing the performance of electrode materials, reducing the characteristics of graphene materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

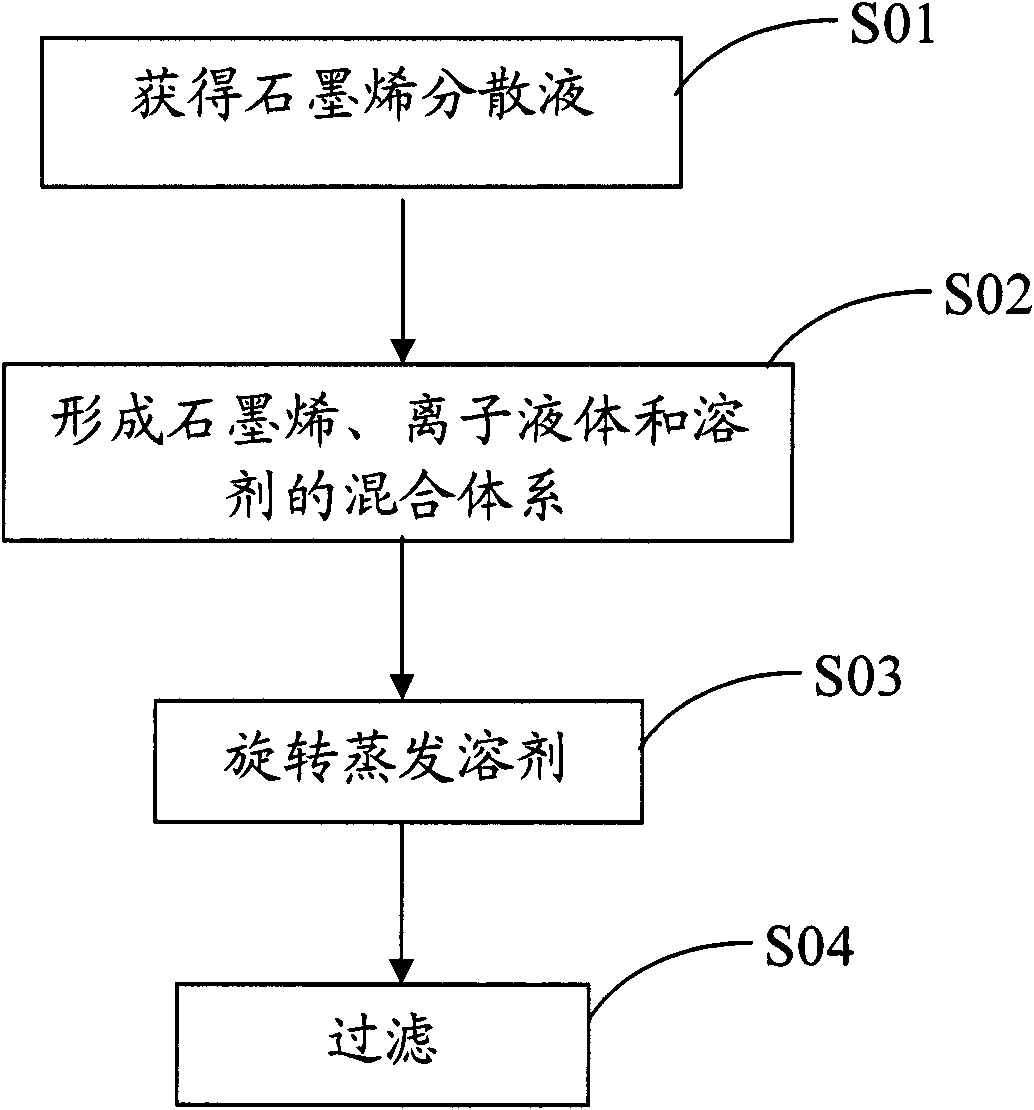

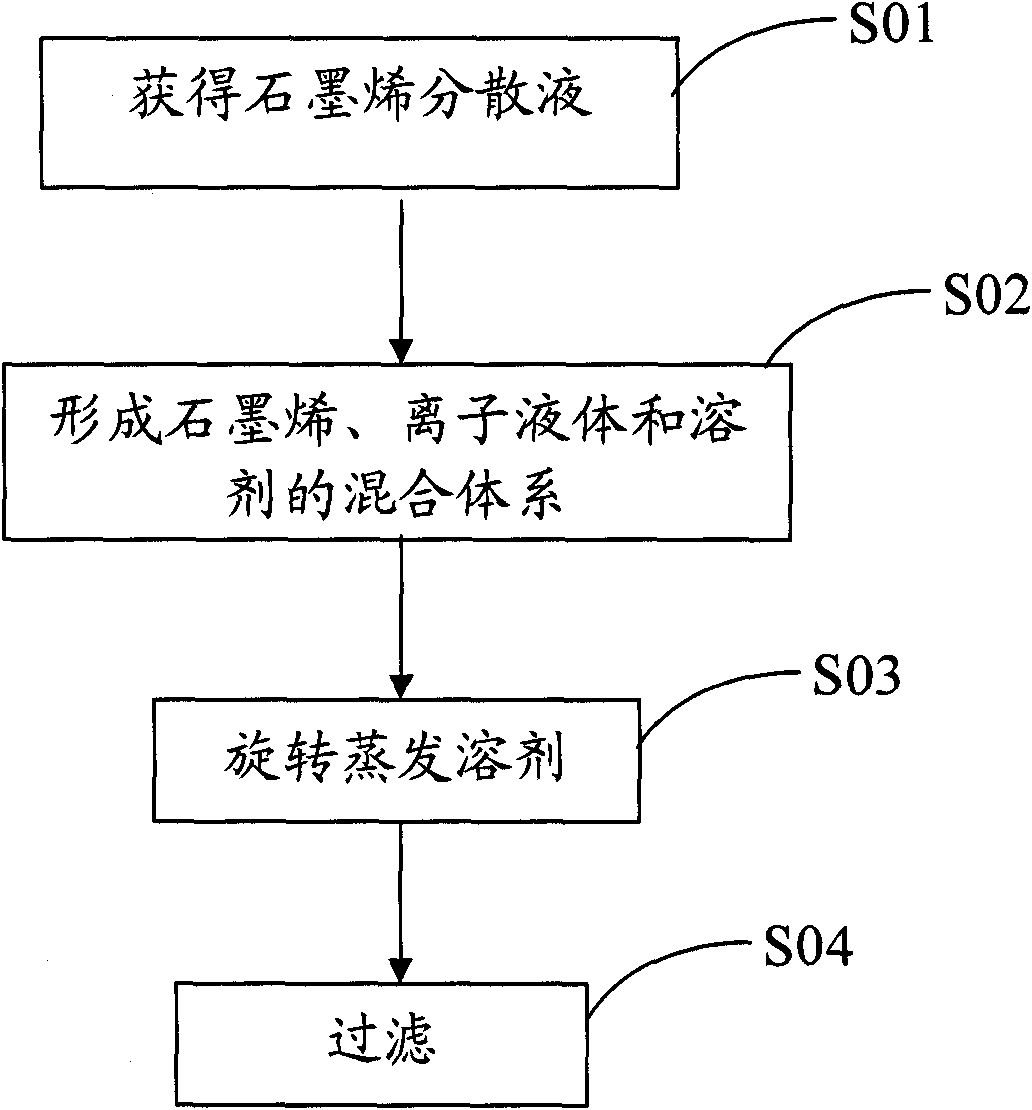

[0026] see figure 1 , showing the preparation method flow chart of the graphene-ionic liquid composite material of the embodiment of the present invention, the method includes the following steps:

[0027] S01, obtain graphene dispersion: provide graphene raw material, dissolve it in a solvent, and perform ultrasonic and heat treatment to obtain graphene dispersion;

[0028] S02, forming a mixed system of graphene, ionic liquid and solvent: in the graphene dispersion, add ionic liquid, and ultrasonically oscillate the ionic liquid at the same time to make it react with graphene to form a mixture of graphene, ionic liquid and solvent system, wherein the ionic liquid has a polar electron cloud structure, and the graphene is a graphene sheet structure;

[0029] S03, rotary evaporation solvent: rotary evaporation removes most of the solvent;

[0030] S04, filtering: filtering the evaporated mixed system to obtain a graphene-ionic liquid composite material, wherein the obtained com...

Embodiment 1

[0038] The preparation method of the graphene-ionic liquid composite material of present embodiment 1 specifically comprises the following steps:

[0039] (1) Obtaining a graphene dispersion: in 100 mL of phenylacetonitrile pentafluoride solvent, add 10 mg of natural graphite, ultrasonically, and heat to obtain a graphene dispersion.

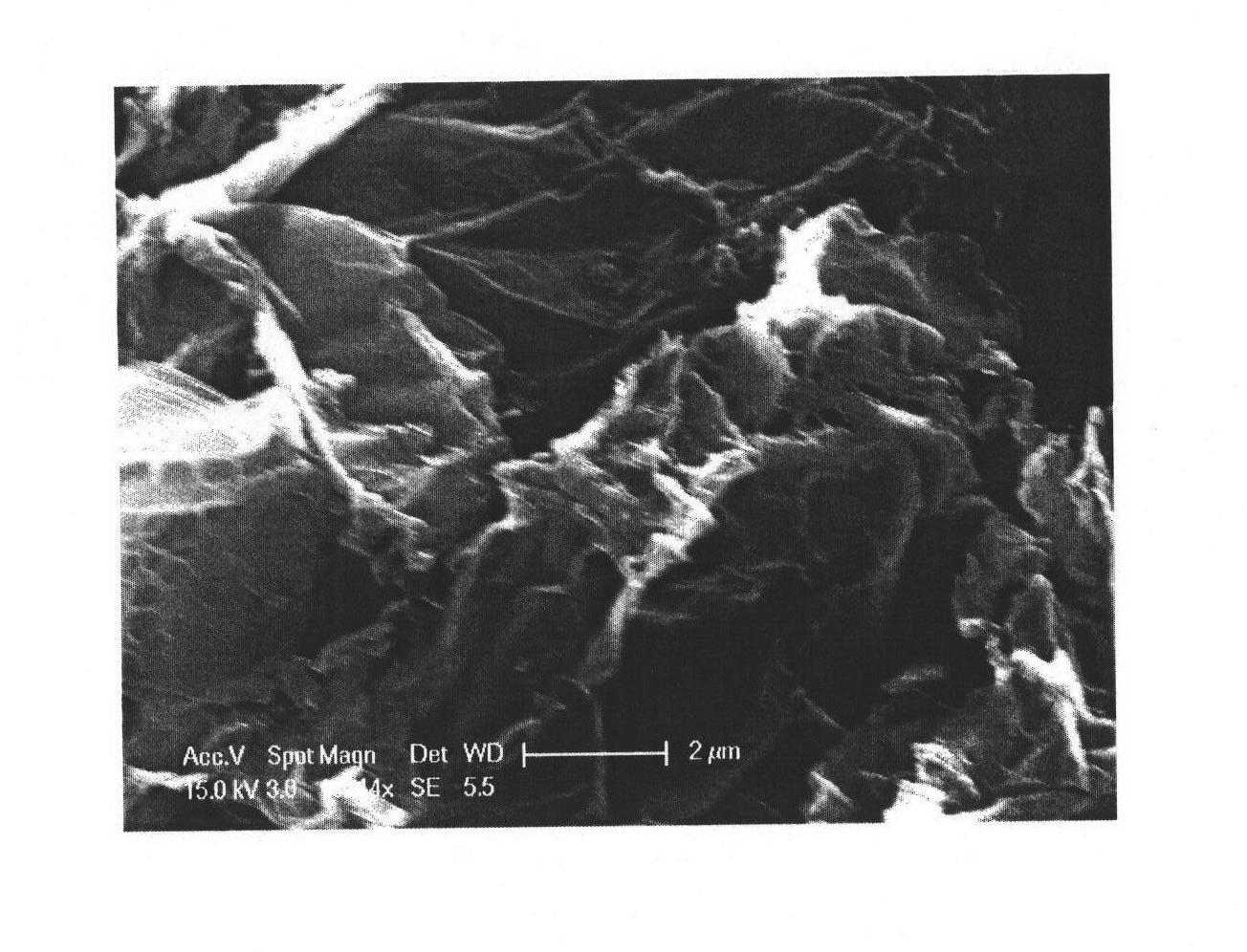

[0040] In order to detect the existence of graphene after the reaction in step (1), the graphene obtained by the reaction can be used for scanning electron microscope observation. see figure 2 , shows the scanning electron micrograph of the graphene that step (1) obtains, as can be seen from the figure, graphene has formed wrinkled sheet-like material, illustrates the formation of graphene sheet-like material.

[0041] (2) Form a mixed system of graphene, ionic liquid and solvent: in the above dispersion, gradually add 10mL of 1-ethyl-3-methylimidazolium tetrafluoroborate ionic liquid as a cosolvent, and The ionic liquid was added dropwise, a...

Embodiment 2

[0045] The preparation method of the graphene-ionic liquid composite material of present embodiment 2 is basically the same as embodiment 1, and the difference is that the solvent in step (1) is replaced with nitropyridine and phenylamine mixed solution, in addition, the added natural stone Ink quality is 1mg, and other steps are basically the same as embodiment 1, finally obtains the composite material of muddy or pasty graphene-ionic liquid, and the removal time of ionic liquid is 12 hours in the present embodiment 2, and graphene accounts for now The mass fraction range is approximately 0.10-20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com