Preparation method of metal mono-atoms

An atom and metal technology, applied in the field of metal single atom preparation, can solve the problems of difficult separation of noble metal catalysts, high catalyst cost, and difficulty in widespread use, and achieve high electrocatalytic activity and stability, high-efficiency application range, and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of the metal single atom proposed by the present invention comprises the following steps:

[0019] (1) Use a precursor and a solvent to form a precursor solution with a mass-volume concentration of 0.01-60 mg / ml. The precursor is a compound of a metal single atom, and the metal single atom is Pt, Ag, Au, Any one of Pd, Rh, Ir, Ru, Co, Ni and Cu, and the solvent is any one of water, ethylene glycol, ethanol, tetraethylene glycol, dimethylformamide or formaldehyde kind;

[0020] (2) freezing the precursor solution prepared in step (1) into ice cubes, processing the ice cubes in a set environment, setting the environment as a light field or a thermal field, to obtain metal monoatomic ice cubes;

[0021] (3) placing the metal monoatomic ice cube obtained in the above step (2) in a dark environment to melt naturally to obtain a metal monoatomic solution;

[0022] (4) Mix the metal single atom solution of the above step (3) with the load material to o...

Embodiment 1

[0028] Preparation of Pt single atoms.

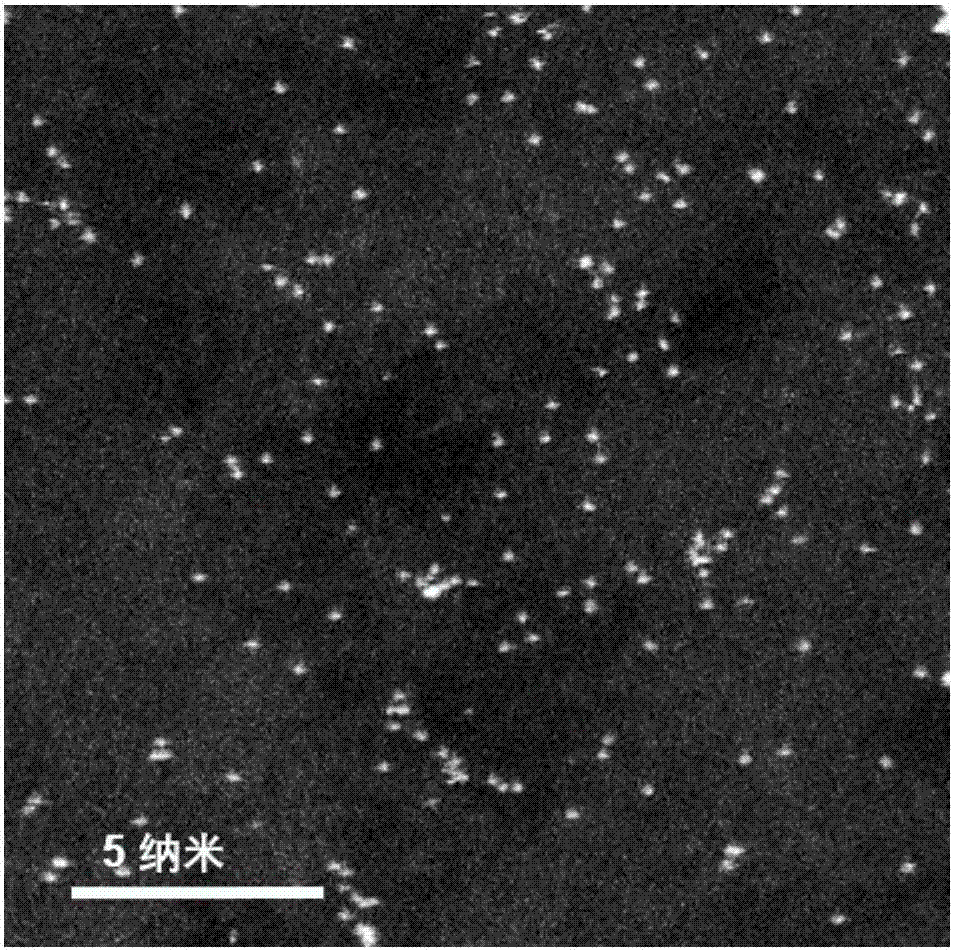

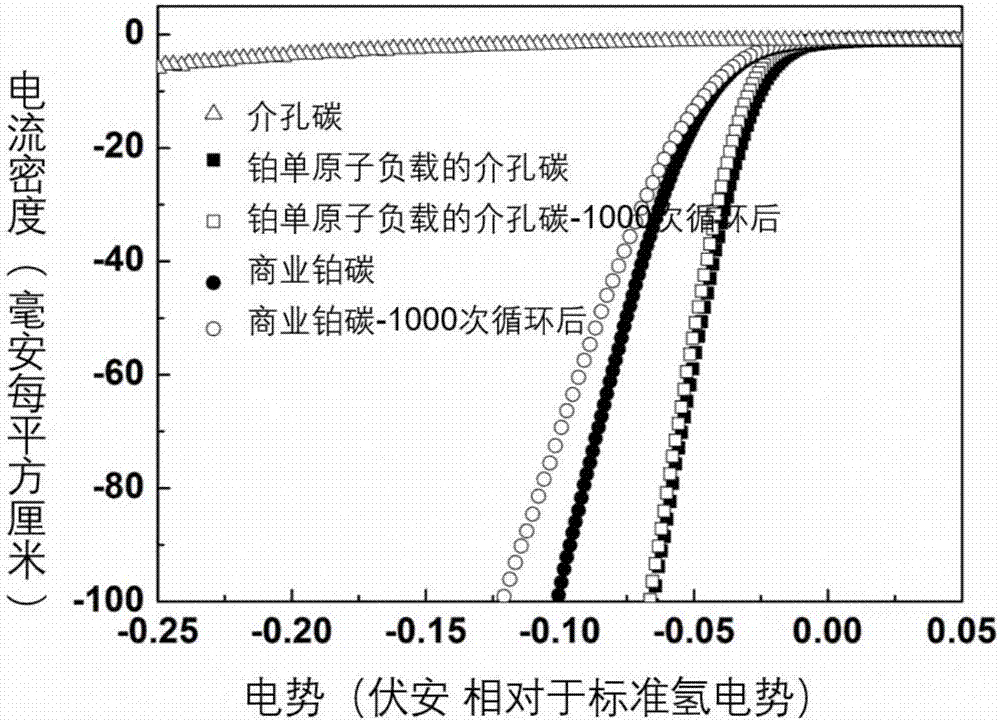

[0029] First, configure the precursor solution that needs to be tested, and use chloroplatinic acid and deionized water to make a 3 mg / ml chloroplatinic acid solution. The configuration environment should be a dark environment to prevent other stray light from affecting the chloroplatinic acid. The solution was snap frozen into ice cubes with liquid nitrogen. Put ice cubes in a freeze dryer at -25°C with a light intensity of 0.89mW / cm 2 UV light for one hour. Finally, the ice cubes after ultraviolet irradiation were stored in a dark environment, and the Pt single-atom solution could be obtained after the ice cubes completely melted naturally. The Pt single atom solution was mixed with the mesoporous carbon solution, wherein the mass percentage of Pt single atom was 3%. The mixed solution was filtered, the filtrate was washed with water until all unreacted precursors were removed, and the filtrate was dried at room temperature for 15 ...

Embodiment 2

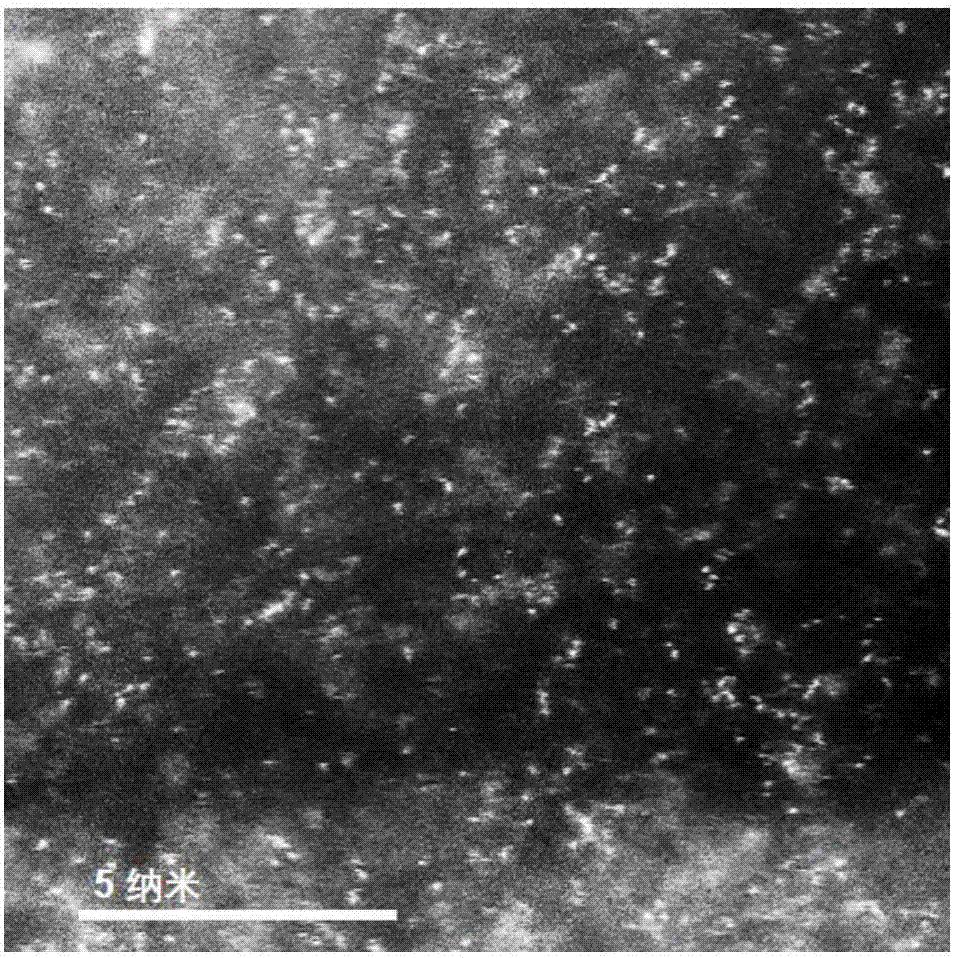

[0031] Preparation of Pt single atoms.

[0032] First, configure the precursor solution that needs to be tested, and use potassium chloroplatinate and a mixture of ultrapure water and ethanol (volume concentration of ethanol is 8%) to prepare a 0.5 mg / ml potassium chloroplatinate solution. The solution was snap frozen into ice cubes with liquid nitrogen. Put ice cubes in a high and low temperature alternating test box at -5°C with a light intensity of 15mW / cm 2 UV light for 5 minutes. Finally, the ice cubes after ultraviolet irradiation were stored in a dark environment, and the Pt single-atom solution could be obtained after the ice cubes completely melted naturally. The Pt single atom solution is mixed with the ZSM molecular sieve solution, wherein the mass percentage of the Pt single atom is 1%. The mixed solution was filtered, the filtrate was washed with water until all unreacted precursors were removed, and the filtrate was dried at room temperature for 15 hours to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com