Fluorine-containing amphiphilic polymer viscosity reducer for crude oil and preparation method thereof

A technology of crude oil viscosity reducer and amphiphilic polymer, which is applied in the field of fluorine-containing amphiphilic polymer crude oil viscosity reducer and its preparation, can solve the problems of poor resistance to mineral salt, etc., and achieve low production cost, easy operation, and high technology easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

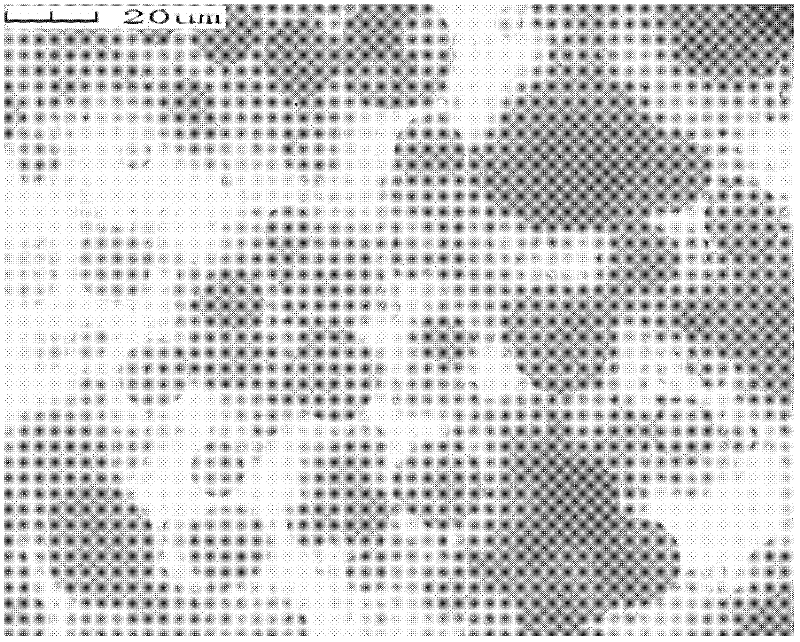

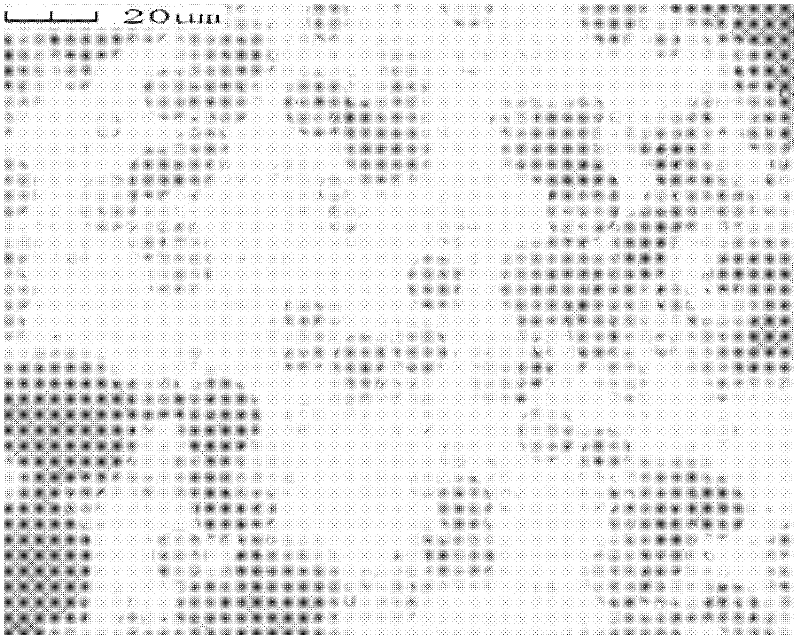

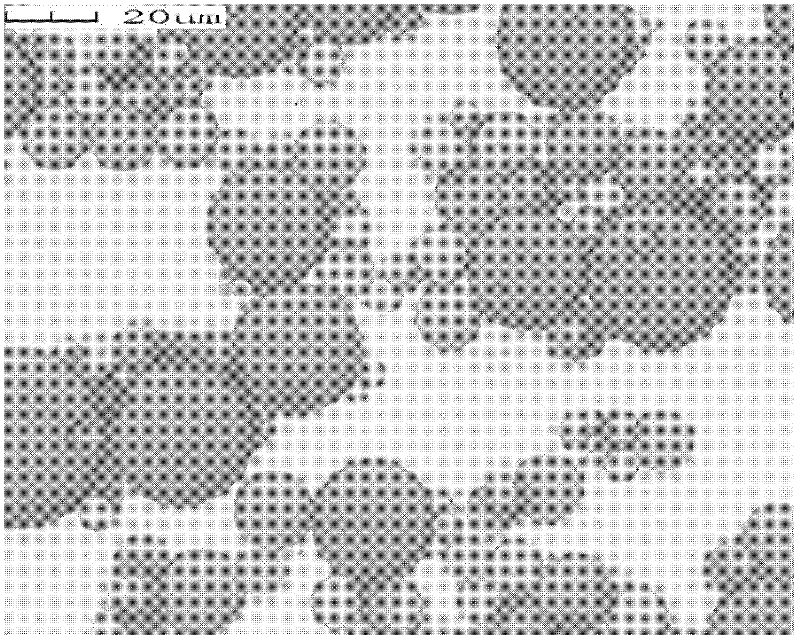

Image

Examples

Embodiment 1

[0025] Embodiment 1, preparation fluorine-containing amphiphilic polymer crude oil viscosity reducer

[0026] 1) 25g of acrylamide, 7.24g of acrylic acid and 0.1056g of CH 2 =CHCOOCH 2 (CF 2 CF 2 ) 3 The perfluoroalkyl acrylate monomer represented by F was dissolved in 50 g of water, and stirred until uniformly mixed to obtain an aqueous phase solution;

[0027] 2) Add 50g cyclohexane, 25g emulsifier (wherein each 12.5g of sorbitan oleate Span80 and polyoxyethylene sorbitan stearate Tween60) and 0.1125g initiator couple Nitroisobutyronitrile AIBN, and stirred at a stirring speed of 15000r / min for 20min to mix to obtain a stable water-in-oil emulsion; in this water-in-oil emulsion, the mass percentage of cyclohexane is 32 %, the mass percentage of the mixture of Span80 and Tween60 is 16%; the mass percentage of AIBN is 0.07%;

[0028] 3) adding alkali sodium hydroxide to the above stable water-in-oil microemulsion to adjust the pH value to 9;

[0029] 4) The above stable...

Embodiment 2

[0036] Embodiment 2, preparation fluorine-containing amphiphilic polymer crude oil viscosity reducer

[0037] 1) 25g acrylamide, 9.5g acrylic acid and 0.2112g CH 2 =CHCOO(CH 2 ) 3 (CF 2 CF 2 ) 6 The perfluoroalkyl acrylate monomer shown in F was dissolved in 50 g of water, and stirred until uniformly mixed to obtain an aqueous phase solution;

[0038] 2) Add 50g cyclohexane, 25g emulsifier (12.5g each of Span80 and Tween60) and 0.2250g initiator AIBN to the above-mentioned solution containing the aqueous phase, and stir at a stirring speed of 10000r / min for 40min until mixed to obtain a stable Water-in-oil emulsion; In this water-in-oil emulsion, the mass percentage of cyclohexane is 31%, the mass percentage of the mixture of Span80 and Tween60 is 15.5%; the mass percentage of AIBN is 0.14%;

[0039] 3) adding alkali sodium hydroxide to the above stable water-in-oil microemulsion to adjust the pH value to 9.5;

[0040] 4) The above stable water-in-oil microemulsion was...

Embodiment 3

[0047] Embodiment 3, preparation fluorine-containing amphiphilic polymer crude oil viscosity reducer

[0048] 1) 25g of acrylamide, 7.32g of acrylic acid and 0.1584g of CH 2 =CHCOO(CH 2 ) 3 (CF 2 CF 2 ) 6 The perfluoroalkyl acrylate monomer shown in F was dissolved in 50 g of water, and stirred until uniformly mixed to obtain an aqueous phase solution;

[0049] 2) Add 50g cyclohexane, 25g emulsifier (12.5g each of Span80 and Tween60) and 0.1687g initiator AIBN to the above-mentioned solution containing the aqueous phase, and stir at a stirring speed of 7500r / min for 30min until mixed to obtain a stable Water-in-oil emulsion; In this water-in-oil emulsion, the mass percentage of cyclohexane is 32%, the mass percentage of the mixture of Span80 and Tween60 is 16%; the mass percentage of AIBN is 0.11%;

[0050] 3) adding alkali sodium hydroxide to the above stable water-in-oil microemulsion to adjust the pH value to 9.5;

[0051] 4) The above stable water-in-oil microemuls...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com