Fire flooding oil extraction method for vertical well gas-injection horizontal well oil extraction

A technology for steam injection wells and horizontal wells, which is applied in wellbore/well components, production fluids, earthwork drilling and production, etc. It can solve intra-layer contradictions, plane contradictions, low-permeability lithology, unsatisfactory oil displacement effects, and affect recovery Efficiency and other issues, to achieve quick results, increase the ultimate recovery, and improve the effect of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

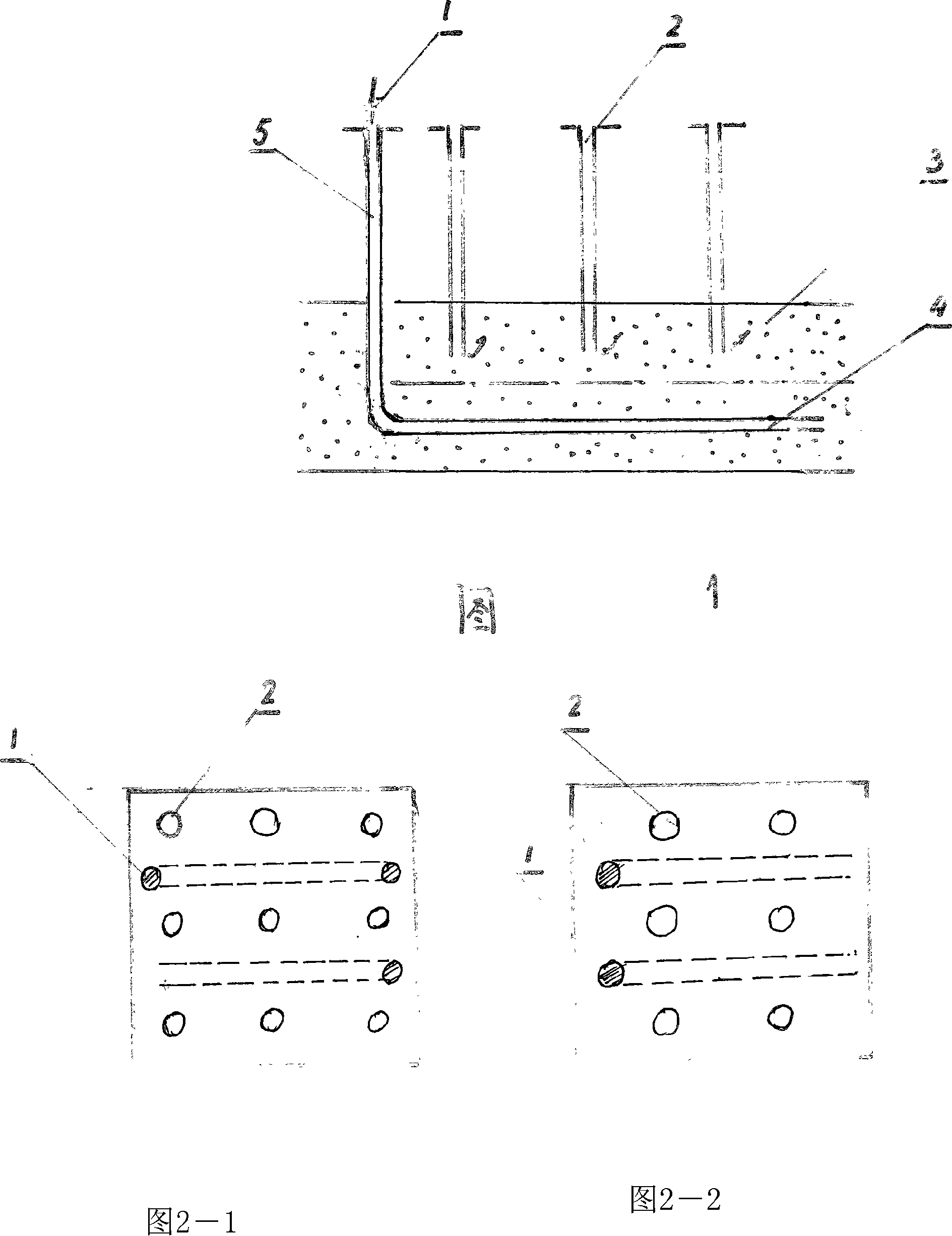

[0024] The ignition method of the fire flooding oil production method for vertical well steam injection and horizontal well oil production is steam injection to stimulate ignition, application number: "2005101308608", which is a steam injection well to inject steam and air into the heavy oil in the well to ignite the oil layer After heating, the heat generated by the fluid and CO 2 The gas accumulates at the top of the oil layer, forming an internal gas cap and pressing on the heavy oil layer, forcing the crude oil to flow into the horizontal well for production under its own weight. Since the horizontal wellbore crosses the heavy oil layer laterally, the steam injection production is not controlled by lithology. It can effectively improve the ultimate recovery factor.

Embodiment 3

[0026] In order to achieve the best recovery rate, it is the key to choose the distance between the steam injection well and the oil production well of the vertical shaft reasonably. For this reason, the distance between the steam injection well 2 in the vertical shaft is 700 meters, and the well distance between the oil production wells is 1 km. The oil production wells can also choose four vertical shaft steam injection wells, one oil production well and eight vertical shaft steam injection wells, and three oil production wells can be used as a well group to carry out fire flooding oil production.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity value | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com