Open hole oil production technology and separated pipe string

A separation pipe and open-hole technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems that the open-hole oil production process cannot be processed in layers, so as to save workover costs, avoid channeling, and comprehensive economy Good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings:

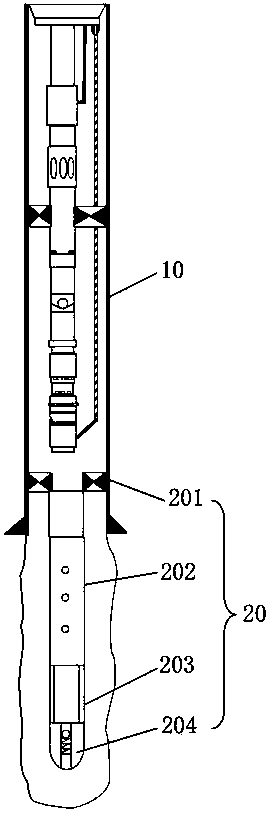

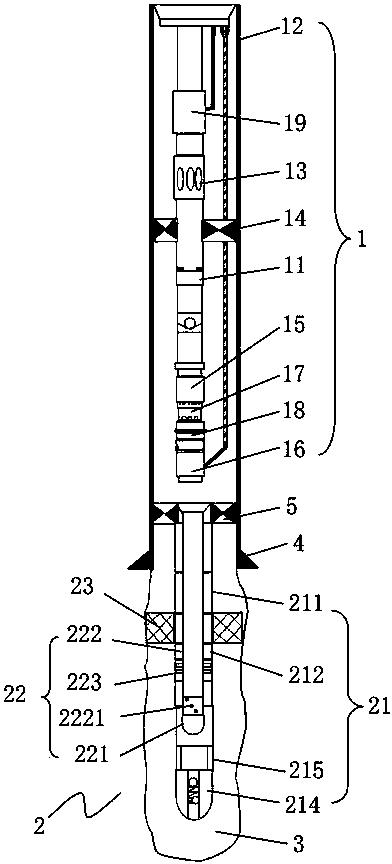

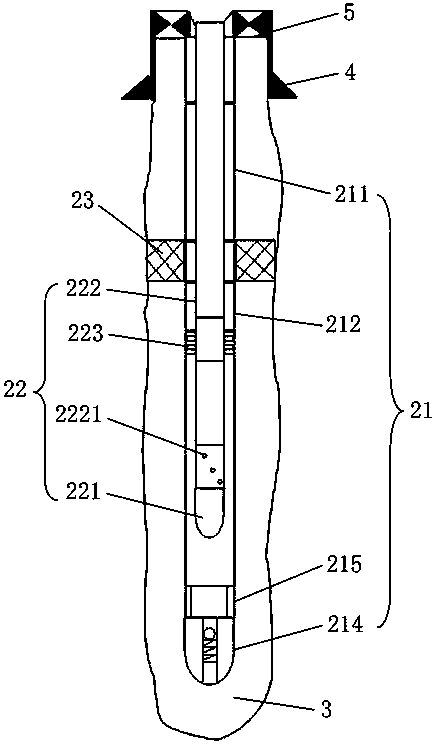

[0071] See figure 2 and image 3 , figure 2 It is a schematic diagram of the structure of the naked-eye oil production equipment in an embodiment of the present invention image 3 It is a schematic diagram of the structure of a divided pipe string according to an embodiment of the present invention. The separating pipe string 2 for open-hole oil production of the present invention is connected to the lower end of the production pipe string 1 for open-eye oil production. The production pipe string 1 includes a working cylinder 11, a tubing hanger 12, a sliding sleeve 13, a packer 14, and an electric submersible pump 15. Motor 16, separator 17, protector 18, downhole safety valve 19, control pipeline, power cable, etc. The mutual positional relationship, connection relationship and function of the above-mentioned componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com