Control method of controlling six-horizon sliding sleeve through three pipelines

A control method and sliding sleeve technology, applied in earthwork drilling, wellbore/well valve devices, wellbore/well components, etc., can solve problems such as affecting recovery rate, poor process applicability, and large interlayer pressure conflicts , to achieve the effects of improving recovery efficiency, strong applicability, and small resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

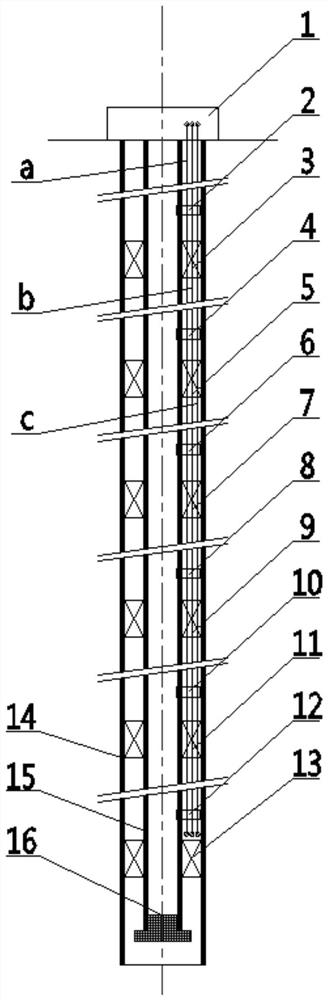

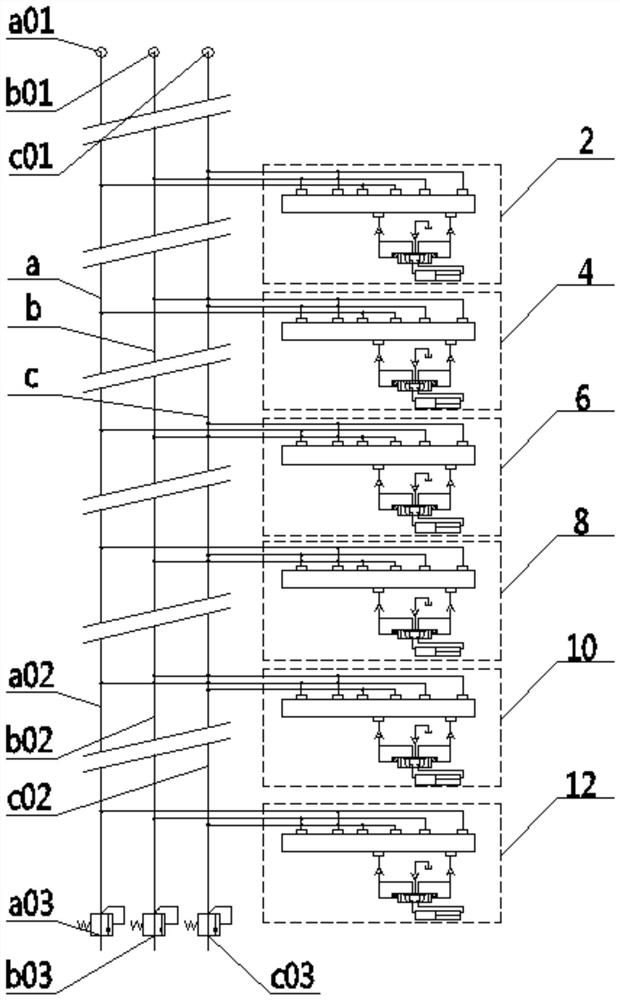

[0035] Such as figure 1 As shown, a downhole hydraulic system with three pipelines controlling six-layer sliding sleeves includes surface hydraulic control equipment (1), downhole hydraulic control system 1 (2), packer 1 (3), and downhole hydraulic control system 2 ( 4), packer 2(5), downhole hydraulic control system 3(6), packer 3(7), downhole hydraulic control system 4(8), packer 4(9), downhole hydraulic control system 5 (10), packer 5 (11), downhole hydraulic control system 6 (12), packer 6 (13), casing (14), tubing (15), tubing plug (16), hydraulic pipeline 1 (a), hydraulic line 2(b), hydraulic line 3(c).

[0036] Wherein, the ground hydraulic control equipment (1) is located on the ground and is used for suspending the casing (14) and the oil pipe (15), and providing hydraulic power for the hydraulic pipeline;

[0037] The hydraulic pipeline 1(a), hydraulic pipeline 2(b) and hydraulic pipeline 3(c) are interposed in the wellbore annulus of the casing (14) and tubing (15...

Embodiment 2

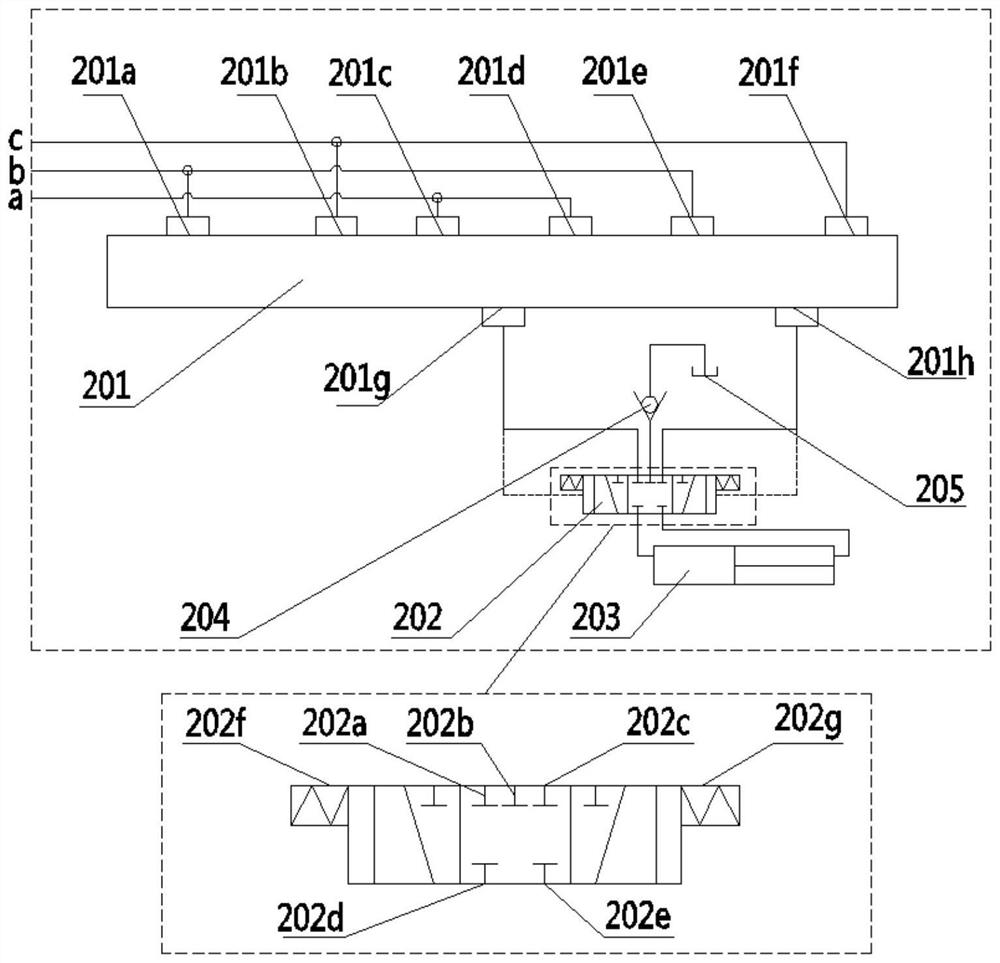

[0045] See attached Figure 10-14 , and specifically introduce the structure of the decoder itself. The structure of the 6 decoders is the same, specifically, the decoder includes the upper joint (A1), the upper valve body (A2), the valve control lock sleeve (A3), the valve control lock ball (A4), the upper return spring ( A5), upper spool (A6), sealing washer (A7), lower valve body (A8), lower spool (A9), lower return spring (A10) and lower joint (A11).

[0046] The upper valve body (A2) and the lower valve body (A8) form the whole valve body through threaded butt joint, and the upper joint (A1) is sealed with the outer port of the upper valve body (A2) through threaded connection, and the lower joint (A11 ) and the outer port of the lower valve body (A8) are sealed by threaded connection.

[0047]Between the upper joint (A1) and the upper valve body (A2) there is a first installation cavity for installing the valve control lock sleeve (A3) (the upper joint has a reduced di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com