Demulsifying agent and preparation method and use thereof

A demulsifier and unsaturated technology, used in chemical instruments and methods, chemical dehydration/demulsification, transportation and packaging, etc., can solve the problems of unsatisfactory demulsification effect, low efficiency, and large amount of demulsifier.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

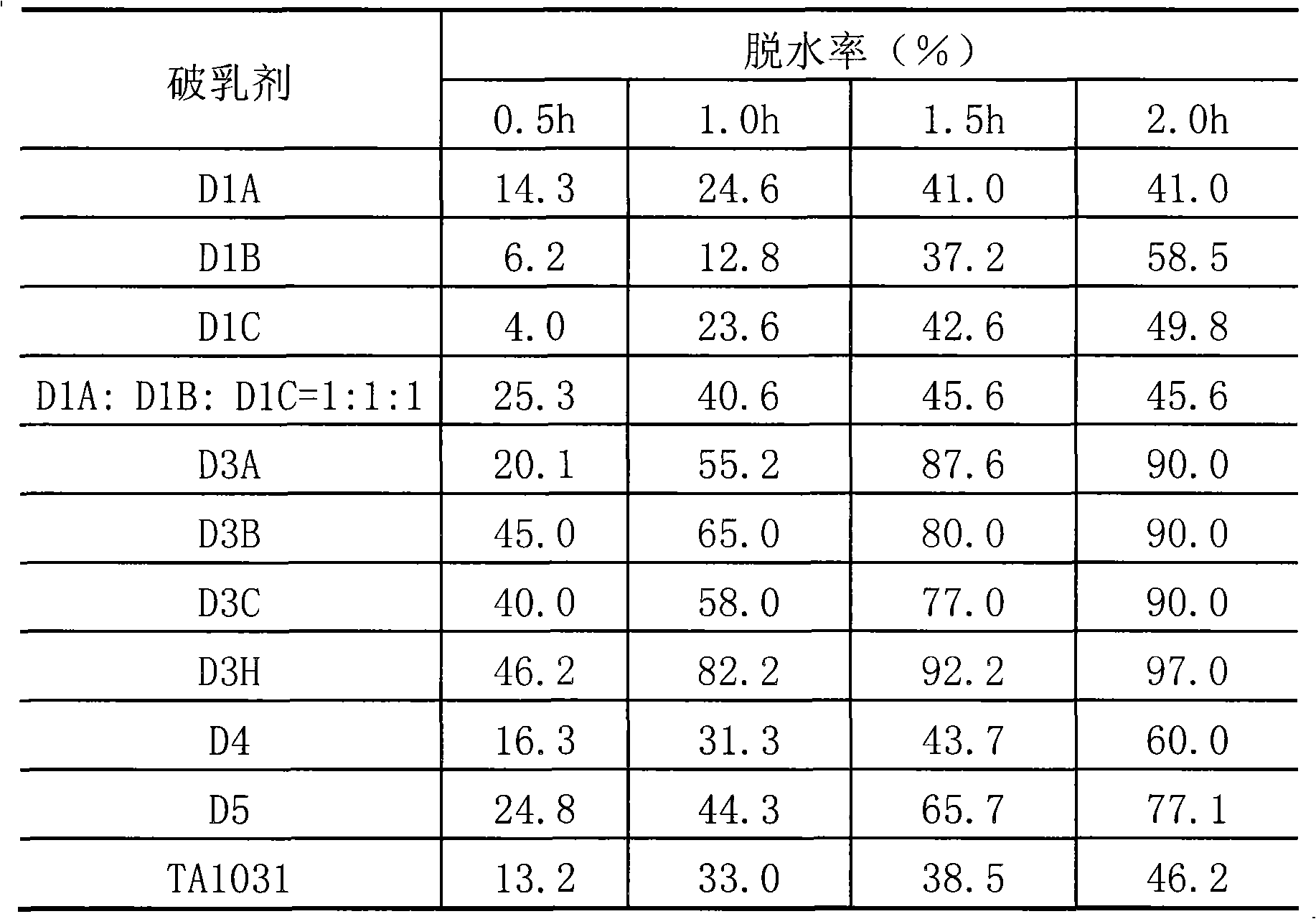

Examples

Embodiment 1

[0034] Add 10g of methanol and 1g of potassium hydroxide to the autoclave, pass nitrogen gas to remove oxygen, raise the temperature to 130°C, add 100g of propylene oxide dropwise, when the reaction pressure no longer decreases, cool down to 110°C, and add 200g of ethylene oxide dropwise , keep warm until the pressure no longer drops, and obtain diblock polyether D1A.

[0035] Add 15g nonylphenolic resin (molecular weight is 1090) and 0.9g potassium hydroxide in autoclave, dropwise add 36.2g propylene oxide, when reaction pressure no longer reduces, add dropwise 65.8g ethylene oxide again, control reaction temperature 130℃, pressure 2.3kg / cm 2 After the reaction of ethylene oxide is complete, 72.5g of propylene oxide is added at this temperature to obtain block polyether D1B.

[0036] Add 5g of tetraethylenepentamine, 2.4g of potassium hydroxide and 400g of propylene oxide into the autoclave, replace with nitrogen 2 to 3 times, raise the temperature to 115°C, keep the tempera...

Embodiment 2

[0038]Add 4.2g of acrylic acid, 50g of D1A polyether, 0.62g of p-toluenesulfonic acid, 0.012g of hydroquinone, and 60ml of toluene into the three-necked flask at one time, install a water separator, stir and heat up to 125-130°C, and reflux for 8h. The esterification product D2A solution was obtained.

[0039] Take the above D2A solution, add acrylic acid 9.3g, styrene 3.3g, benzoyl peroxide 3.1g, toluene 50ml, in N 2 Under ambient temperature and 85°C, react for 8 hours, and distill off the solvent to obtain the polymer product D3A.

Embodiment 3

[0041] Add 0.85g of acrylic acid, 100g of D1B polyether, 0.9g of p-toluenesulfonic acid, 0.0034g of hydroquinone, and 173ml of toluene to the three-necked flask at one time, install a water separator, and reflux for 8 hours to obtain the esterification product D2B solution.

[0042] Take the above D2B solution, add acrylic acid 4.3g, styrene 4.3g, benzoyl peroxide 3.0g, in N 2 Under ambient temperature and 85°C, react for 8 hours, and distill off the solvent to obtain the polymer product D3B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com