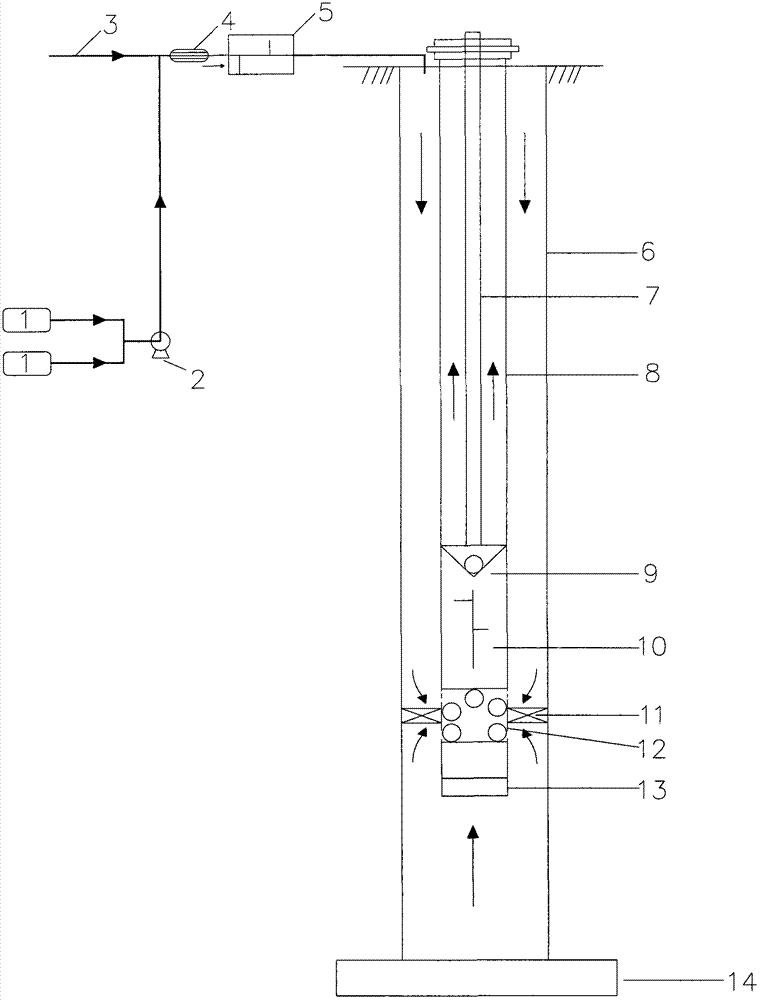

Method and device for reducing viscosity of shaft applicable to extremely-viscous oil recovery

A viscosity-reducing and wellbore technology, applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve the problems of imperfect process conditions and poor performance of viscosity-reducing agents, saving thin oil rate and reducing production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The present invention is applied to the TH12329 mechanically pumped well of Tahe Oilfield to carry out the field test of viscous reduction of heavy oil. The solution of SDG-2 composite viscosity reducer (publication number CN102604621A) developed by China University of Petroleum (Beijing) is housed in the drug storage tank 1.

[0035] The preparation steps of this viscosity reducer are:

[0036] (1) Preparation of oil-soluble viscosity reducer:

[0037] Mixed aromatics (50% by mass): toluene, ethylbenzene (1:1)

[0038] Alcohols (50% by mass): ethanol, octanol, pentanol (1:1:1);

[0039] Preparation method: Mix the above components at normal temperature and pressure, and stir to obtain.

[0040] (2) Preparation of water-soluble viscosity reducer

[0041] Fatty alcohol ether carboxylate is: CH 3 (CH 2 ) 8 O(CH 2 CH 2 O) 8 CH 2 COONa.

[0042] Preparation:

[0043] Add 0.1mol structural formula to the reactor AEOs 8 , under strong stirring and slight heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com