Temperature-resistant salt-tolerant viscous-oil biological viscosity reducer and preparation method thereof

A bio-viscosity reducer, temperature-resistant and salt-resistant technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of large catalyst damage, high development cost, difficult biodegradation, etc., to prevent pipeline scaling Corrosion, no secondary pollution, easy biodegradable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

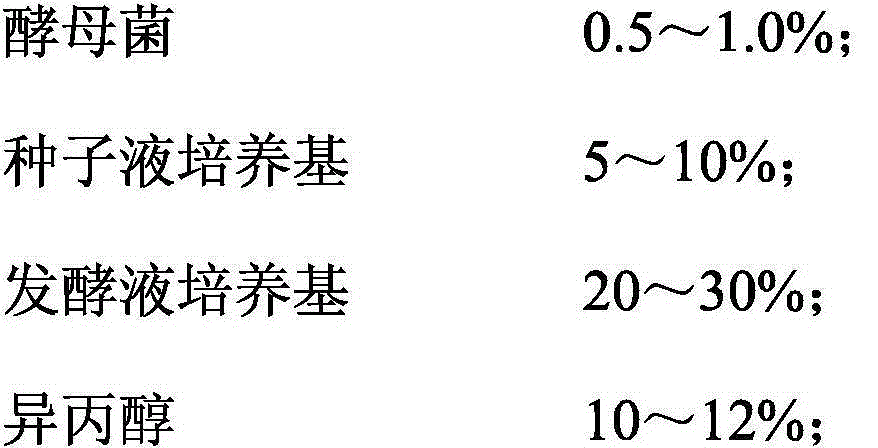

[0028] A temperature-resistant and salt-resistant heavy oil biological viscosity reducer A, its composition and mass percentage components are as follows:

[0029]

[0030] The rest is water.

[0031] The yeast is Candida globosa, and the composition and components of the seed liquid medium are: glucose 300g, yeast powder 120g, KH 2 PO 4 60g, MgSO 4 ·7H 2 020g, the composition and components of the fermentation broth medium are: sucrose 1200g, peptone 400g, potassium dihydrogen phosphate 350g and potassium sulfate 50g.

[0032] A preparation method of a temperature-resistant and salt-resistant heavy oil bio-viscosity reducer A, specifically comprising the following steps:

[0033] (1) Preparation of yeast seed solution

[0034] First, clean and sterilize the 20L Erlenmeyer flask, add 10L distilled water to the sterilized Erlenmeyer flask, then add 50g yeast, 300g glucose, 120g yeast powder, 60gKH 2 PO 4 and 20gMgSO 4 ·7H 2 O, cultivated on a constant temperature sh...

Embodiment 2

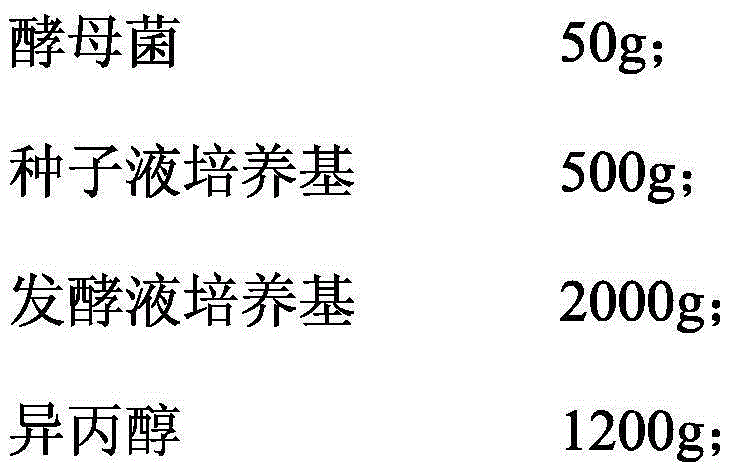

[0045] A temperature-resistant and salt-resistant heavy oil biological viscosity reducer B, its composition and mass percentage components are as follows:

[0046]

[0047] The rest is water.

[0048] The yeast is Candida globosa, and the composition and components of the seed liquid medium are: glucose 480g, yeast powder 192g, KH 2 PO 4 54g, MgSO 4 ·7H 2 024g, the composition and components of the fermentation medium are: molasses 1200g, corn steep liquor 360g, dipotassium hydrogen phosphate 380g, sodium sulfate 60g.

[0049] A preparation method of a temperature-resistant and salt-resistant heavy oil bioviscosity reducer B, specifically comprising the following steps:

[0050] (1) Preparation of yeast seed solution

[0051]First, clean and sterilize the 20L Erlenmeyer flask, add 10L distilled water to the sterilized Erlenmeyer flask, then add 50g yeast, 480g glucose, 192g yeast powder, 54gKH 2 PO 4 , 24gMgSO 4 ·7H 2 O, cultivated on a constant temperature shaker ...

Embodiment 3

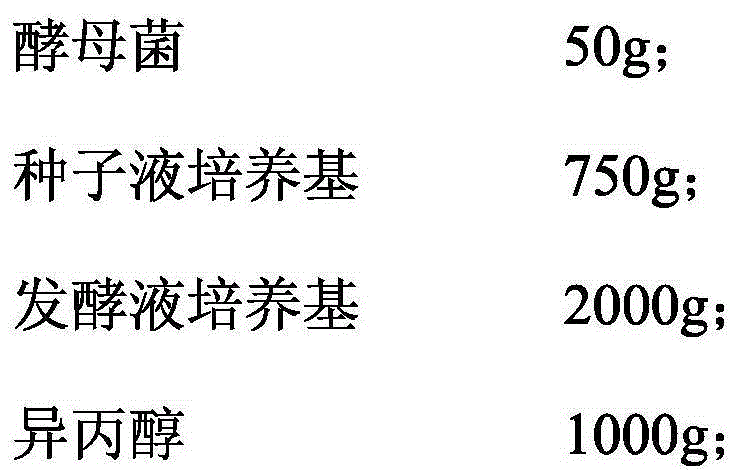

[0062] A temperature-resistant and salt-resistant heavy oil biological viscosity reducer C, its composition and mass percentage components are as follows:

[0063]

[0064] The rest is water.

[0065] The yeast is Candida globosa, and the composition and components of the seed liquid medium are: glucose 620g, yeast powder 250g, KH 2 PO 4 95g, MgSO 4 ·7H 2 035g, the composition and components of the fermentation broth culture medium are: oil 2000g, peptone 450g, potassium phosphate 470g, potassium phosphate 80g.

[0066] A preparation method of temperature-resistant and salt-resistant heavy oil bioviscosity reducer C, specifically comprising the following steps:

[0067] (1) Preparation of yeast seed solution

[0068] First, clean and sterilize the 20L Erlenmeyer flask, add 10L distilled water to the sterilized Erlenmeyer flask, then add 50g yeast, 620g glucose, 250g yeast powder, 95gKH 2 PO 4 and 35gMgSO 4 ·7H 2 O, cultivated on a constant temperature shaker at a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com