Circulated water system of thermal power plant

A technology of circulating water system and thermal power plant, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of water resource waste, system fouling, etc., achieve water saving, reasonable sewage control, and avoid fouling The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

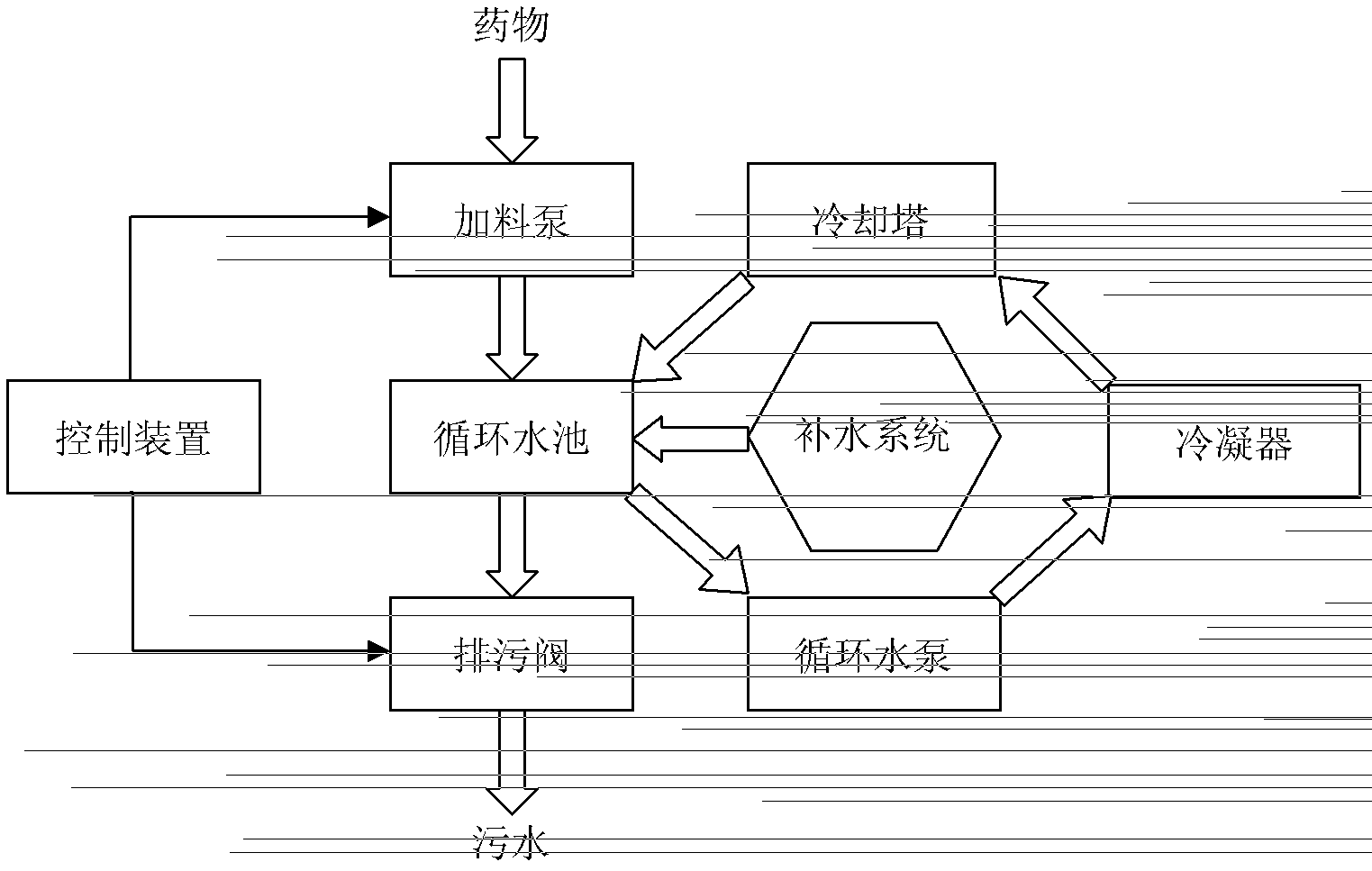

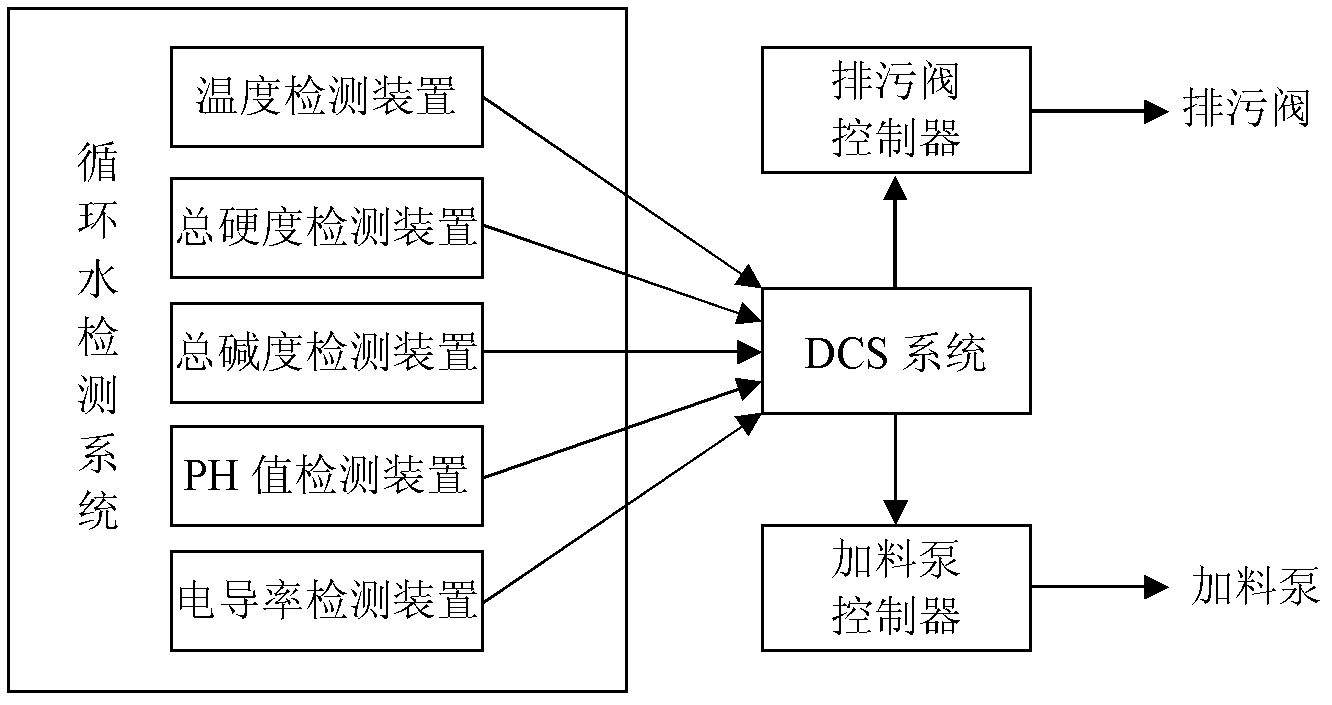

[0039] In this example, the circulating water system of the thermal power plant, such as figure 1 As shown, it includes circulating water pool, circulating water pump, condenser, cooling tower, control device, blowdown valve and feeding pump. The circulating water pool, circulating water pump, condenser, and cooling tower are connected in sequence through pipelines to form a circulating cooling system. The supplementary water system in the figure is used to supplement when the water level of the circulating water pool is lower than the set value due to sewage discharge and evaporation. In this example, the control device is figure 2As shown, including DCS system, circulating water detection system, blowdown valve controller and feed pump controller. The circulating water detection system in the figure is composed of a temperature detection device, a total hardness detection device, a total alkalinity detection device, a pH value detection device and a conductivity detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com