Multi-slug surfactant combined oil displacement system suitable for low-permeability reservoir and preparation method of multi-slug surfactant combined oil displacement system

A surfactant flooding and surfactant technology, which is applied in the field of chemical flooding, can solve the problem of difficult to improve the water absorption profile of low-permeability reservoirs with strong heterogeneity, low sweep efficiency and oil-washing efficiency of injected fluid, and low-permeability reservoirs. The problem of low production degree, etc., can achieve the effects of expanding sweep efficiency, reducing oil-water interfacial tension, and ultra-low oil-water interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

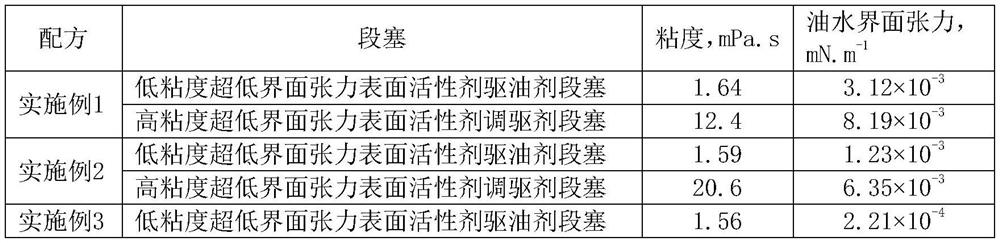

Embodiment 1

[0045] 1. The multi-slug surfactant combined oil displacement system is composed of a low-viscosity ultra-low interfacial tension surfactant flooding slug and a high-viscosity ultra-low interfacial tension surfactant regulating flooding agent slug. Wherein said low-viscosity ultra-low interfacial tension surfactant oil displacement agent slug, comprises the component of following mass percentage:

[0046] {Di[N-methyl-N-(3-dodecyloxy-2-hydroxy)propanyl-N-(2-hydroxy-3-sulfonate sodium)propanyl]ammonium chloride}ethane: 0.2 %,

[0047] Nonionic-Anionic Surfactant Sodium Laureth Sulfate: 0.15%,

[0048] Chelating agent EDTA: 0.14%,

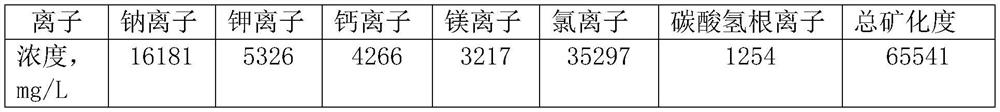

[0049] Formation water salinity: 65541mg / L,

[0050] The balance is water,

[0051] Among them, the {bis[N-methyl-N-(3-dodecyloxy-2-hydroxyl)propanyl-N-(2-hydroxyl-3-sulfonate sodium)propanyl]ammonium chloride} The structural formula of ethane is:

[0052] It is a Gemini surfactant of the hydroxysultaine type.

[0053] The {di[N-methyl-N-(3-...

Embodiment 2

[0062] 2. The multi-slug surfactant combined oil displacement system is composed of a low-viscosity ultra-low interfacial tension surfactant flooding slug and a high-viscosity ultra-low interfacial tension surfactant regulating flooding agent slug. Wherein said low-viscosity ultra-low interfacial tension surfactant oil displacement agent slug, comprises the component of following mass percentage:

[0063] {Di[N-methyl-N-(3-dodecyloxy-2-hydroxy)propanyl-N-(2-hydroxy-3-sulfonate sodium)propanyl]ammonium chloride}ethane: 0.25 %,

[0064] Nonionic-Anionic Surfactant Sodium Laureth Sulfate: 0.2%,

[0065] Chelating agent EDTA: 0.04%,

[0066] Formation water salinity: 65541mg / L,

[0067] The balance is water,

[0068] Among them, the {bis[N-methyl-N-(3-dodecyloxy-2-hydroxyl)propanyl-N-(2-hydroxyl-3-sulfonate sodium)propanyl]ammonium chloride} The structural formula and preparation method of ethane are the same as in Example 1.

[0069] Wherein said high-viscosity ultra-low in...

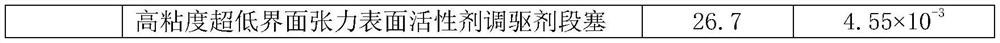

Embodiment 3

[0077] 2. The multi-slug surfactant combined oil displacement system is composed of a low-viscosity ultra-low interfacial tension surfactant flooding slug and a high-viscosity ultra-low interfacial tension surfactant regulating flooding agent slug. Wherein said low-viscosity ultra-low interfacial tension surfactant oil displacement agent slug, comprises the component of following mass percentage:

[0078] {Di[N-methyl-N-(3-dodecyloxy-2-hydroxy)propanyl-N-(2-hydroxy-3-sulfonate sodium)propanyl]ammonium chloride}ethane: 0.3 %,

[0079] Nonionic-Anionic Surfactant Sodium Laureth Sulfate: 0.35%,

[0080] Chelating agent EDTA: 0.10%,

[0081] Formation water salinity: 65541mg / L,

[0082] The balance is water,

[0083] Among them, the {bis[N-methyl-N-(3-dodecyloxy-2-hydroxyl)propanyl-N-(2-hydroxyl-3-sulfonate sodium)propanyl]ammonium chloride} The structural formula and preparation method of ethane are the same as in Example 1.

[0084] Wherein said high-viscosity ultra-low in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com