Food dipping method based on strong electrolyte ion current controlled by function signal

A technology of strong electrolyte and functional signal, applied in the field of strong electrolyte dipping solution and new food dipping processing, can solve the problems of dipping food fermentation and rancidity, and achieve the effect of avoiding electrolysis and plate corrosion and scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 Salted Greengage

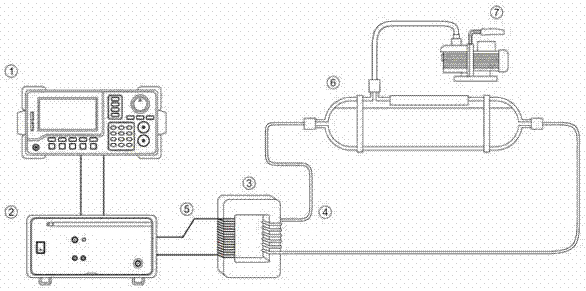

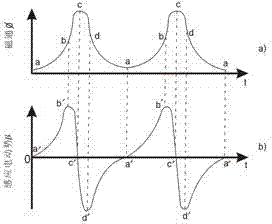

[0022] Weigh 300 grams of greengage, wash and place in the dipping tank, the cavity size of the tank is 80mm in inner diameter, 300mm in length, and 3mm in wall thickness. Inject sodium chloride pickling solution with a mass fraction of 5% until the sample is submerged. At this time, the conductivity of the pickling solution measured by a Mettler-Toledo FE30 conductivity meter is 55mS / cm. After the immersion tank is sealed, turn on the vacuum pump to evacuate until the solution fills the silicone pipeline, and the immersion solution in the system is in a loop state. Among them, the material of the silicone tube is a food-grade platinum silicone tube with good insulation, good flexibility, non-toxic and tasteless, the inner diameter is 2mm, and the thickness of the tube wall is 3mm. The silicone tube is wound on one end of the rectangular silicon steel core, and the winding of the silicone tube is a single-layer winding. , the range of tu...

Embodiment 2

[0024] Calcium nutrition fortification of apples in embodiment 2

[0025] Wash and peel the apples, cut them into 3×3×3cm blocks, weigh 400g, and put them in the dipping tank. The cavity of the dipping tank has an inner diameter of 80mm, a length of 300mm, and a wall thickness of 3mm. Inject food with a mass fraction of 1000mg / kg. Grade calcium lactate solution submerges the sample. At this time, the conductivity of the pickling solution measured by the Mettler-Toledo FE30 conductivity meter is 22mS / cm. After sealing, turn on the vacuum pump to evacuate until the solution is filled with the silica gel pipeline, and the solution in the system forms a loop. The silicone tube material is a food-grade platinum silicone tube with good insulation, good flexibility, non-toxic and tasteless, the inner diameter range is 4mm, the tube wall thickness is 3mm, the silicone tube is wound on one end of the rectangular silicon steel mutual induction core, and the silicone tube winding is singl...

Embodiment 3

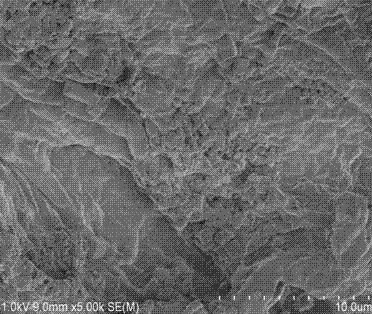

[0027] Embodiment 3: Melon seeds coloring

[0028] Using synthetic pigment amaranth, molecular formula C 20 h 11 o 10 N 2 S 3 Na 3 , Water-soluble pigments. This example is for the stable coloring of the plant fiber surface. Weigh 500 grams of sunflower seeds and put them in the dipping tank. The cavity of the dipping tank has an inner diameter of 80mm, a length of 300mm, and a wall thickness of 3mm. The amaranth dipping solution with a concentration of 40mg / kg is injected until the sample is immersed. At this time, a Mettler- The conductivity of the pickling solution measured by Toledo FE30 conductivity meter is 20mS / cm. After sealing, turn on the vacuum pump to evacuate until the solution is filled with the silicone tube, and the solution in the system forms a loop state. The silicone tube material is a food-grade platinum silicone tube with good insulation, good flexibility, non-toxic and tasteless, and the inner diameter range is 5mm. The thickness is 3mm, the sili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com