A recovery system for desalinated water to absorb waste heat from thermal power plants

A recovery system and thermal power plant technology, applied in heat recovery systems, preheating, supplementary water supply, etc., can solve problems such as heat waste, and achieve the effects of reducing consumption, reducing consumption, and reducing waste heat emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

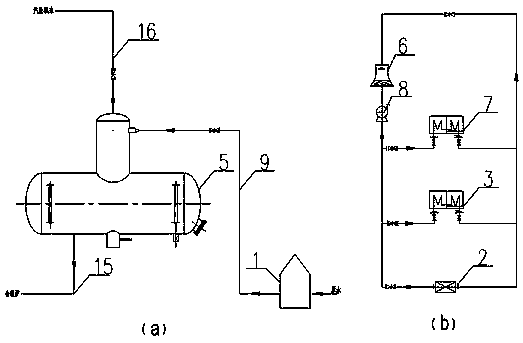

Method used

Image

Examples

Embodiment 1

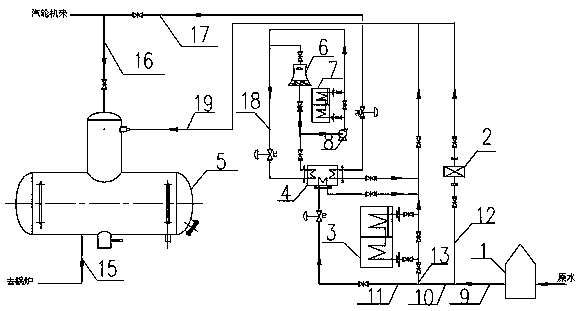

[0021] like figure 2 shown.

[0022] A recovery system for desalinated water to absorb waste heat in a thermal power plant, which includes a water treatment device 1, a desalinated water recovery slag cooler waste heat device 2, a steam seal cooler 3, a heat pump 4, a deaerator 5, a cooling tower 6, and a maintenance cooling device 7 , the desalinated water of the water treatment device 1 is divided into multiple branches, and the waste heat of the slag cooler 2, the steam seal cooler 3, and the heat pump 4 are merged into the main pipeline 19 and entered into the deaerator 5 through the desalinated water, and the specific connection structured as figure 2 as shown, figure 2 The desalinated cold water pipeline 9 after treatment by the reclaimed water treatment device 1 is divided into one road, enters the desalted water recovery slag cooler waste heat device 2 to absorb heat, and enters the main pipe 19 through the first branch road 12, and enters the other road through t...

Embodiment 2

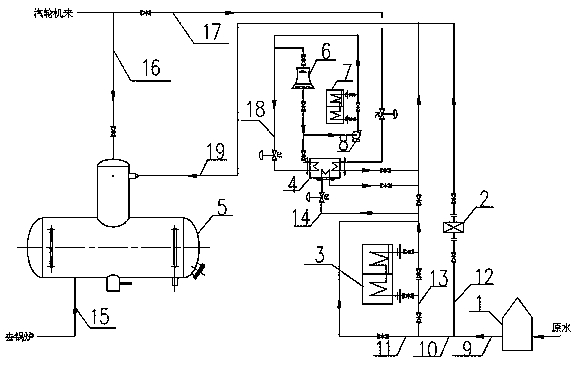

[0025] like image 3 shown.

[0026] A recovery system for desalinated water to absorb waste heat in a thermal power plant, which includes a water treatment device 1, a desalinated water recovery slag cooler waste heat device 2, a steam seal cooler 3, a heat pump 4, a deaerator 5, a cooling tower 6, and a maintenance cooling device 7 , the desalinated water of the water treatment device 1 is divided into multiple branches, and the waste heat of the slag cooler 2, the steam seal cooler 3, and the heat pump 4 are merged into the main pipeline 19 and entered into the deaerator 5 through the desalinated water, and the specific connection structured as image 3 as shown, image 3 The demineralized cold water pipeline 9 treated by the water treatment device 1 is divided into one path through the first branch 12 and enters the desalinated water recovery slag cooler waste heat device 2 to absorb heat and then enters the main pipeline 19, and the other path passes through the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com