Method for preparing cement-based light transparent material by applying optical fiber parallel arrangement process

A technology of light-transmitting materials and parallel arrangement, applied in manufacturing tools, ceramic molding machines, etc., can solve the problems of immaturity and little research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

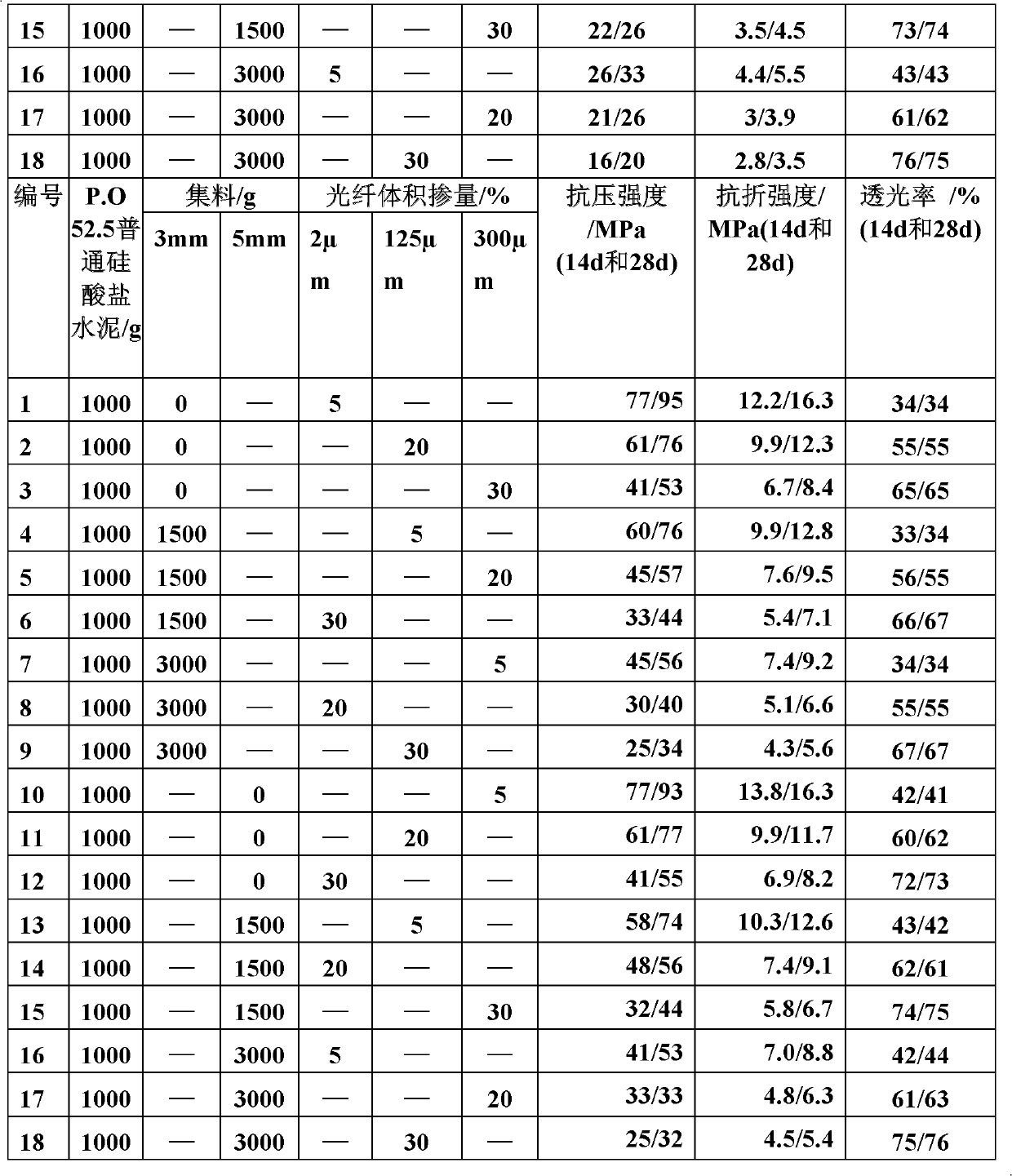

[0019] The raw materials used in the implementation example are as follows: the cement is P.O 32.5 colored cement and P.O 52.5 ordinary Portland cement, both of which have a quality of 1000g, and the water-cement ratios of the mortars prepared are 0.4 and 0.45 respectively, and the water-cement ratios of the prepared mortars are respectively 0.28 and 0.33; two kinds of aggregates are selected, the maximum particle diameters are 3mm and 5mm respectively; the water reducer is a naphthalene-based high-efficiency water reducer produced by the Swiss SIKA company with a water reducing rate greater than 15%, and the water-cement ratio is 0.4 and The dosage of 0.45 mortar is 12g and 9g respectively, and the dosage of clean slurry with water-cement ratio of 0.28 and 0.33 is respectively 4g and 2g; the measured water-cement ratio is 0.4 and 0.45, and the aggregate dosage is 3000g Consistency is 11cm and 14cm respectively, the consistency of mortar with aggregate content of 1500g is 12cm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com