Horizontal well-cementation expandable cement mortar and preparation method thereof

A technology for cement slurry and horizontal wells, which is applied in wellbore/well components, chemical instruments and methods, earthwork drilling and production, etc. It can solve the problems of inability to improve the quality of interface cementation, adverse effects of later production operations, and increase in the elastic modulus of cement stones, etc. problems, to achieve the effect of on-site operation feasibility, good settlement stability and micro-expansion characteristics, and improved compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

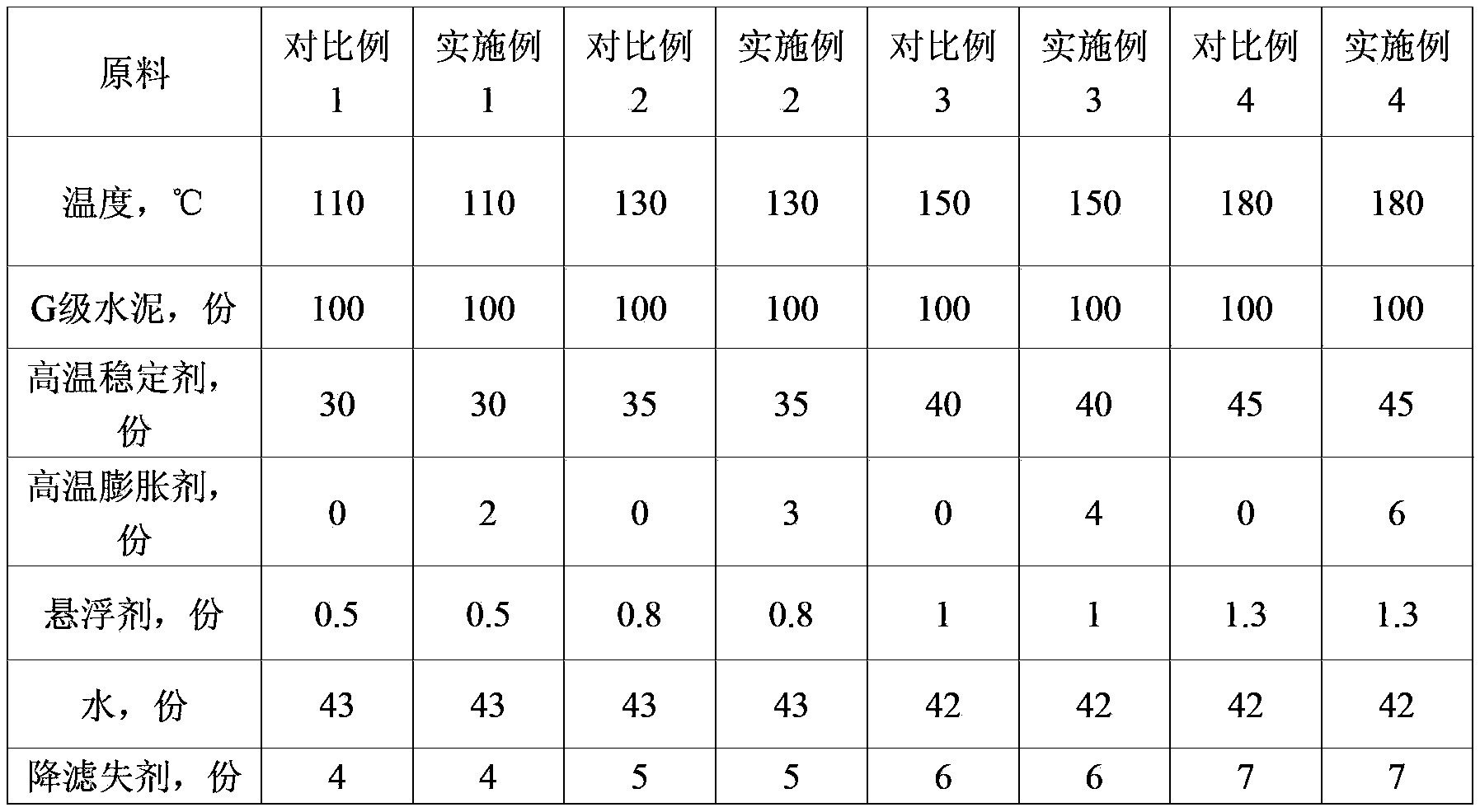

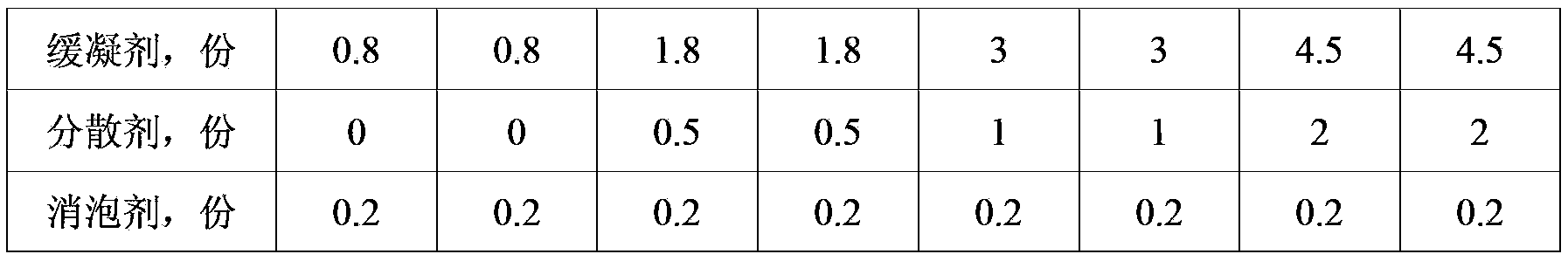

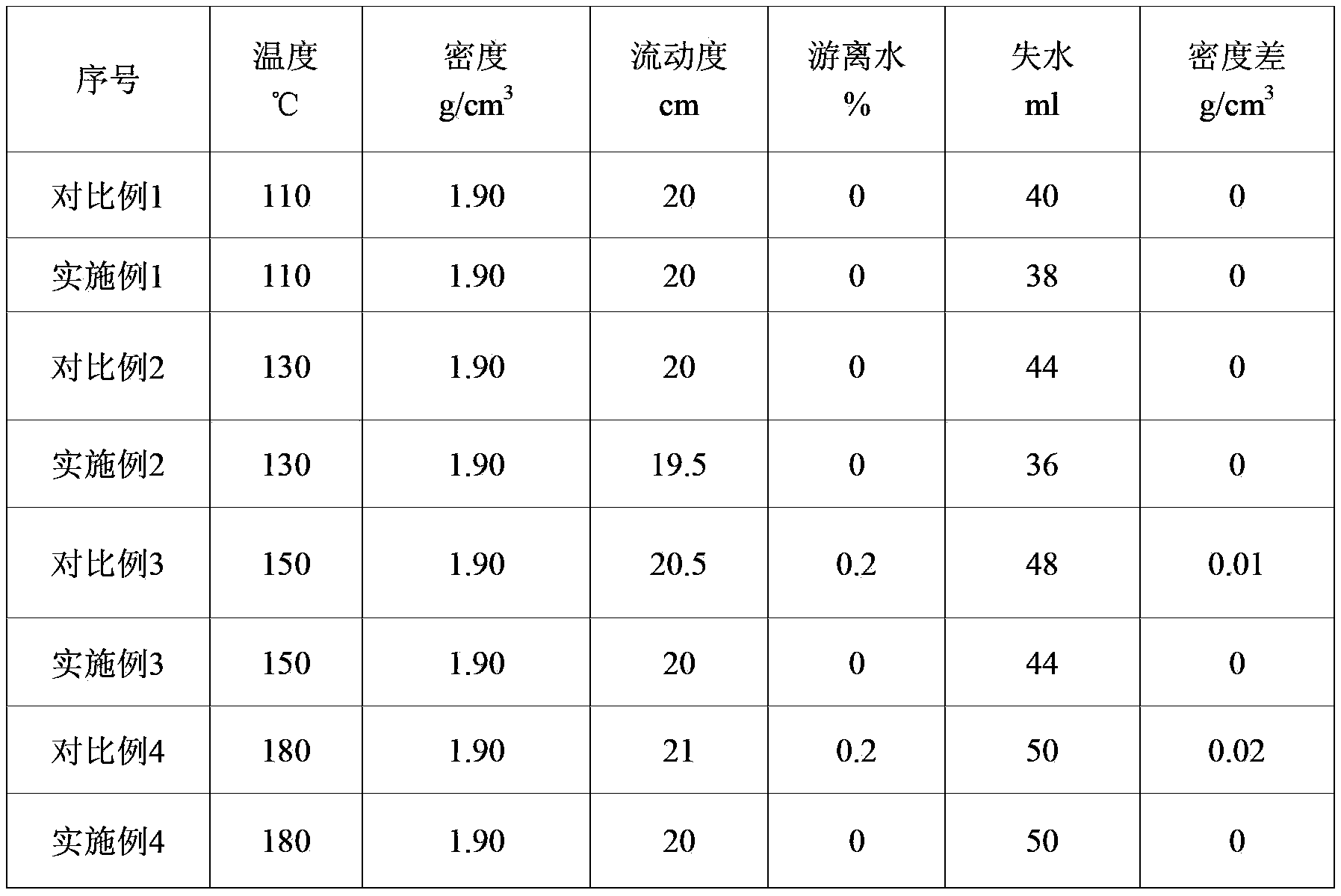

[0041] A horizontal well cementing expansion cement slurry and a preparation method thereof,

[0042] In view of the fact that the drilling and cementing of horizontal wells tends to be deep wells and ultra-deep wells, the cementing faces high temperature and ultra-high temperature, which requires high performance of cement slurry. However, many cement slurry systems have poor settlement stability under high temperature and ultra-high temperature conditions. The cement stone system shrinks, which affects the cementing quality and has the risk of oil and gas channeling. Aiming at the current difficulties faced by high-temperature and ultra-high-temperature horizontal well cementing, an expansive cement slurry for horizontal well cementing and its preparation method are invented.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com