Improved rotary ice feeding system and operating method thereof

An ice-feeding and ice-feeding technology, which is applied to rotary conveyors, conveyors, transportation and packaging, etc., can solve problems such as affecting the efficiency of ice body transportation, the quality of ice output, reducing economic benefits, and affecting the strength of wind pressure, etc. Achieve the effect of improving conveying efficiency and conveying quality, eliminating material accumulation, and ensuring smooth feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

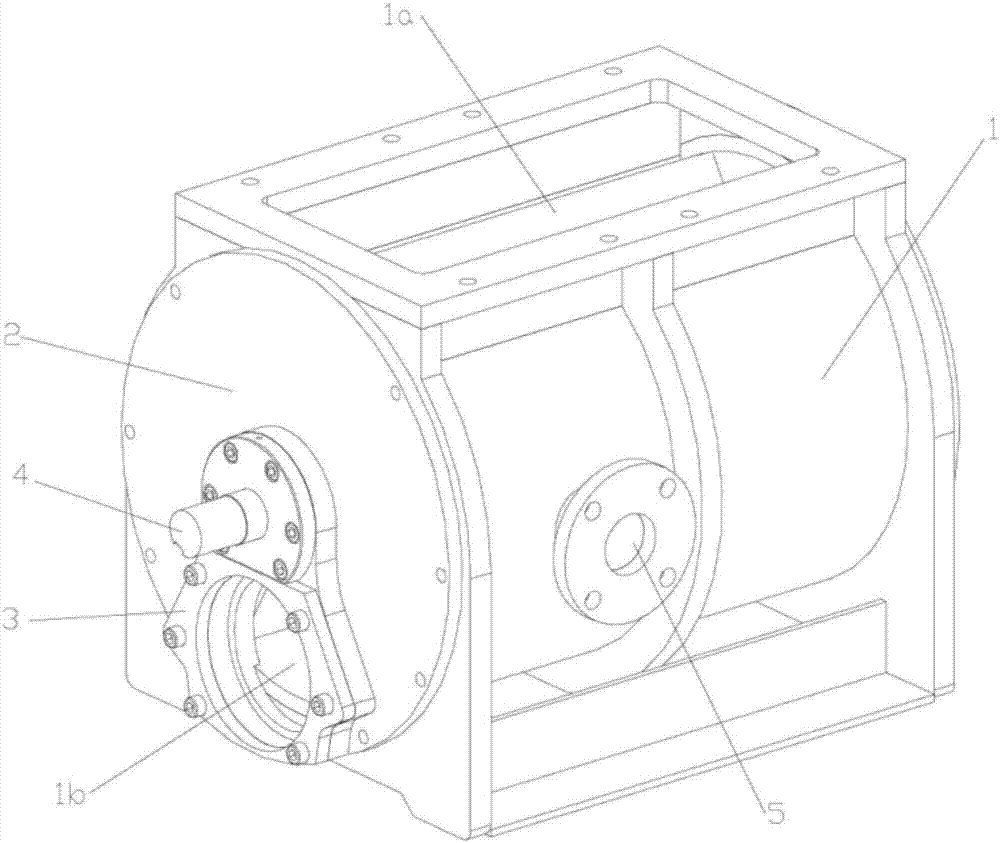

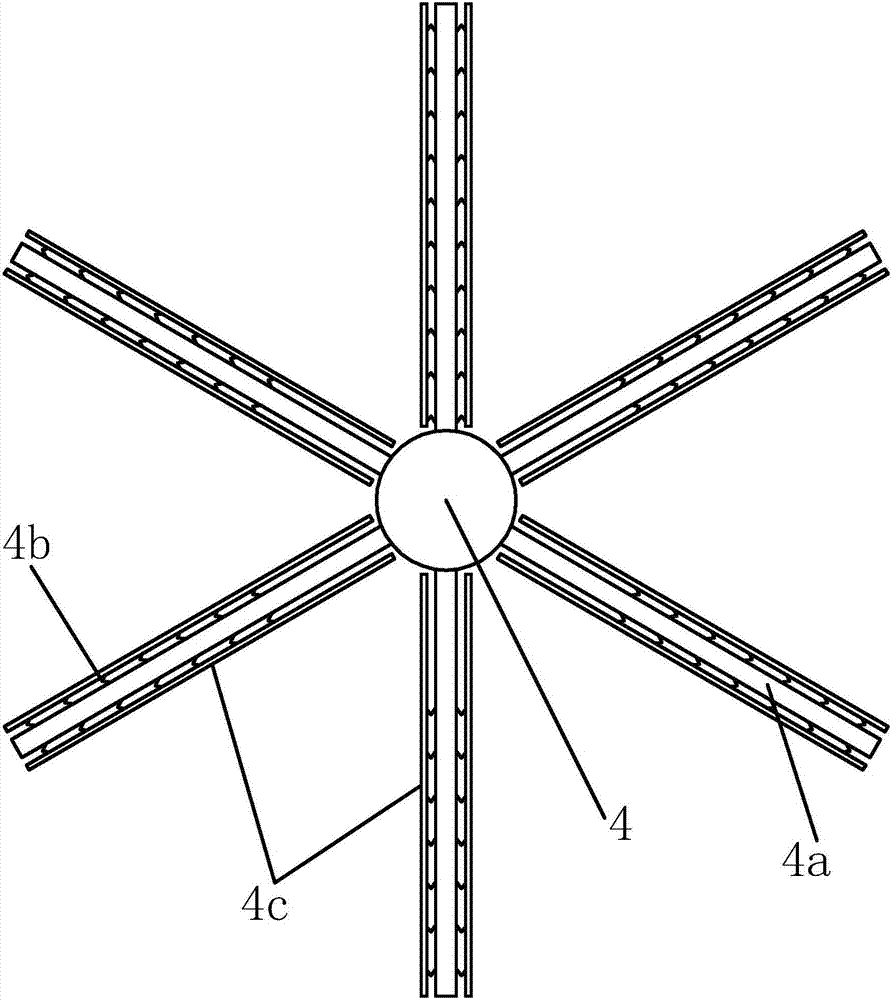

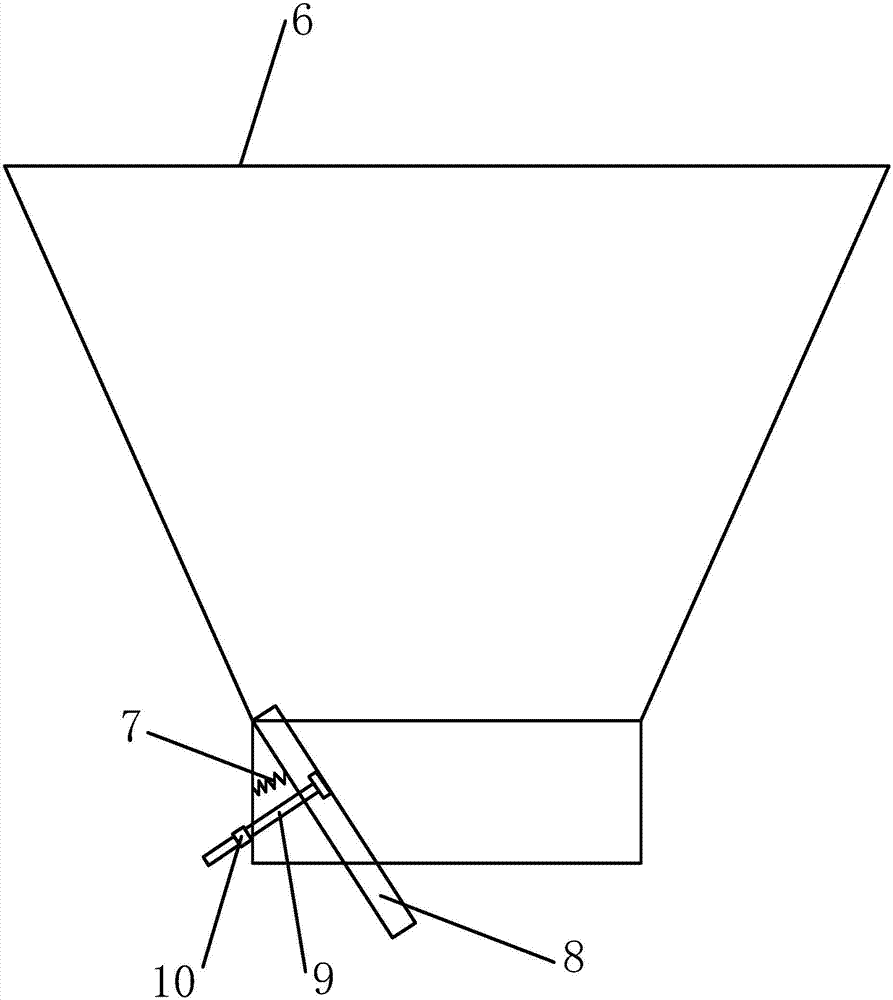

[0026] like figure 1 , figure 2 and image 3 As shown, the improved rotary ice delivery system includes an ice hopper 6, a rotary ice supplier, a blower, and an ice delivery pipeline. The rotary ice supplier includes a cylindrical casing 1, and the top of the casing 1 is provided with a discharge opening 1a. , the two ends of the casing 1 open the ice delivery port, the discharge port of the ice hopper 6 is located directly above the discharge port 1a, the blower is sealed and connected to the ice delivery port at one end of the casing 1, and the ice delivery pipe is sealed and connected to the casing 1 At the other end of the ice delivery port, a material guide plate 8 is provided at the outlet of the ice hopper 6, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com