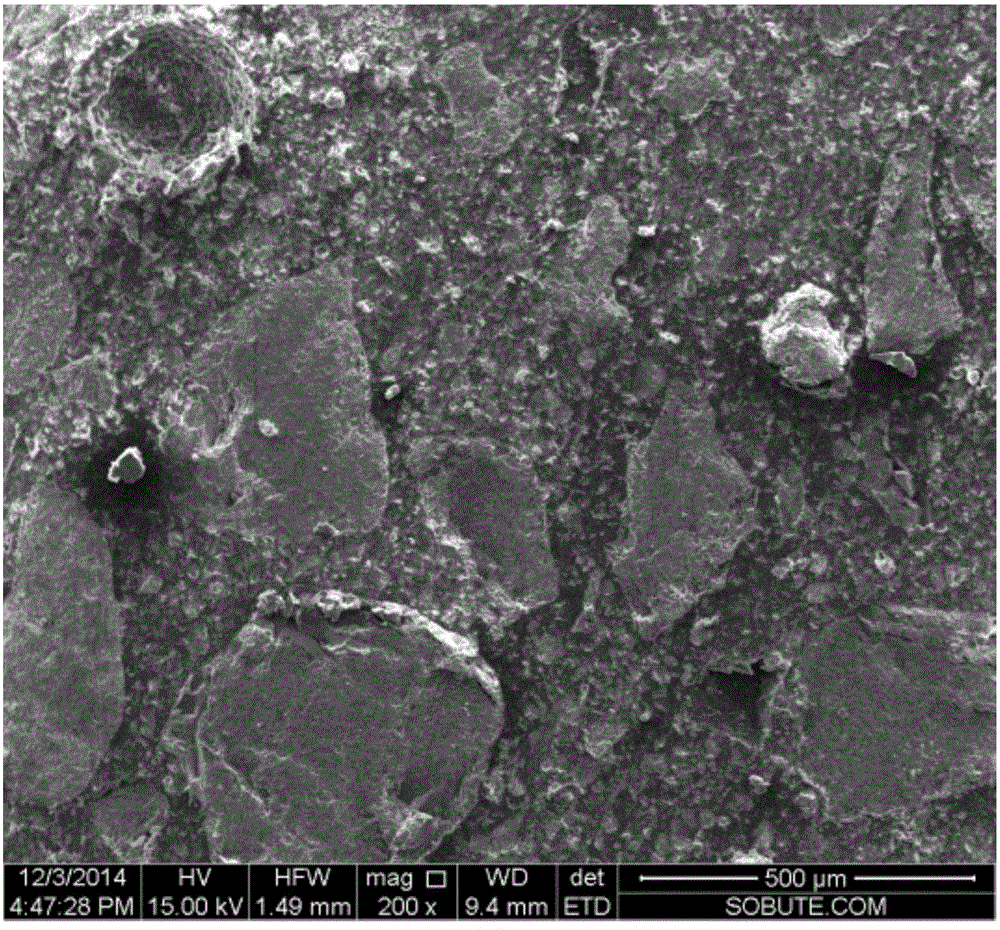

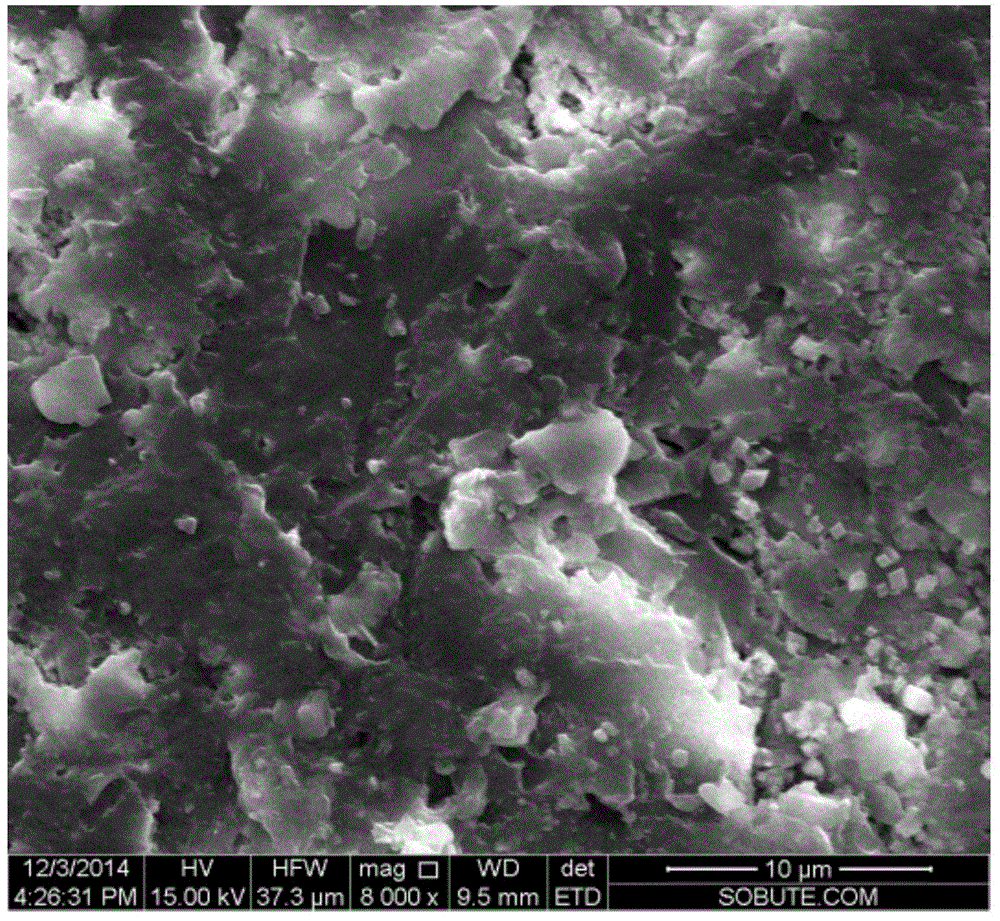

A kind of micro-expansion self-healing polyurethane waterproof mortar and preparation method thereof

A polyurethane waterproof and self-healing technology, applied in the field of building materials, can solve problems such as poor compatibility, and achieve the effects of good compatibility, convenient construction and good micro-expansion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 4 parts of polyether polyol resin N220 (functionality 2, molecular weight 2000, Tianjin Petrochemical), 50 parts of castor oil polyol resin H-306 (functionality 2, molecular weight 660, Ito Oil Co., Ltd.), 0.05 part of emulsifier OP-10, stirring and mixing in a 60°C reactor, 1200r / min high-speed shear dispersion, adding 15 parts of water successively, and emulsifying for 30min to obtain the complex polyol emulsion system A1.

Embodiment 2

[0037]4 parts of polyether polyol resin N220 (functionality 2, molecular weight 2000, Tianjin Petrochemical), 5 parts of N330 (functionality 3, molecular weight 3000, Tianjin Petrochemical), castor oil polyol resin HF-1300 (functionality 2, molecular weight 1068~1496 (Ito Oil Co., Ltd.) 45 parts, 0.05 parts of emulsifier OP-10, 0.03 parts of emulsifier AEO, stirring and mixing in a 60°C reactor, 2000r / min high-speed shear dispersion, adding 25 parts of water successively, emulsifying for 30min , to obtain complex polyol emulsion system A2.

Embodiment 3

[0039] 20 parts of polyether polyol resin N220 (functionality 2, molecular weight 2000, Tianjin Petrochemical), 3 parts of polyester polyol NIPPOLLAN 121E (Xiamen Aikema Chemical Raw Materials Co., Ltd.), polyether polyol N403 (functionality 4, Molecular weight 300, Jiangsu Zhongshan Chemical Industry), 25 parts of castor oil polyol resin Polycin GR-50 (functionality 2.2, molecular weight 2610, U.S. Vertellus company), 0.12 part of emulsifier alkylphenol polyoxyethylene polyoxypropylene ether (brand sea petrochemical), 0.03 parts of emulsifier SDS, stirring and mixing in a 60°C reactor, dispersing at a high speed of 1000r / min, adding 30 parts of water successively, and emulsifying for 30 minutes to obtain a complex polyol emulsion system A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com