Expansive force terminal strain clamp of composite core aluminum-stranded conductor

A technology of tension-resistant clamps and aluminum stranded wires, applied in the direction of adjusting/maintaining mechanical tension, which can solve the problems of small contact surface, many edges and corners on the outside of the device, loss of power supply facilities, etc., to achieve stable radial pressure, reduce discharge phenomenon, The effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

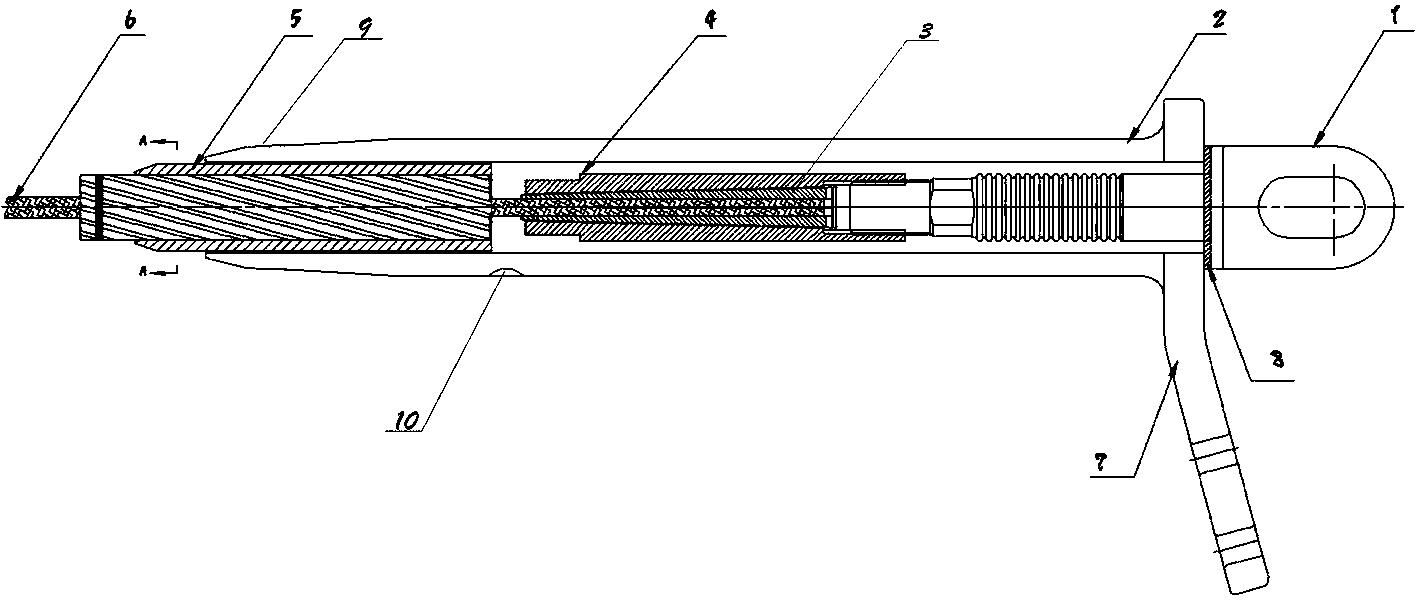

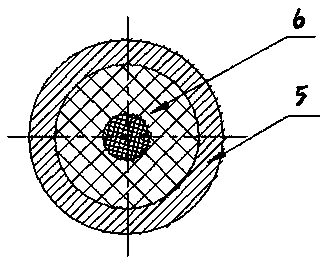

[0018] In the implementation mode, the composite core aluminum stranded wire is inserted into the inner liner (5), and then passed through the tension sleeve (2), the outer layer of the composite core aluminum stranded wire is stripped to expose the wire core (6), and the wire The core (6) penetrates the tension jacket (4), and then penetrates the tension sandwich core (3), and the tension sandwich core (3) is placed in the tension jacket (4), and the spinning steel anchor ( The secondary thread of 1) is screwed to the tension jacket (4), radially pushes the tension sandwich (3), then pushes the spinning steel anchor (1) into the tension jacket (2), and It is screwed and fixed with the tension casing (2), and at the same time, the inner liner (5) is placed in the front end of the tension casing, and finally the crimping point (9) and the burst point (10) are squeezed and fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com