Defibering and fiber-adding process and equipment of tobacco stems of rolling process reconstituted tobacco

A technology of reconstituted tobacco leaves and rolling method, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of uneven fiber addition, poor taste, complicated process, etc., and achieves good comprehensive effects, reduces production costs, and overcomes damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

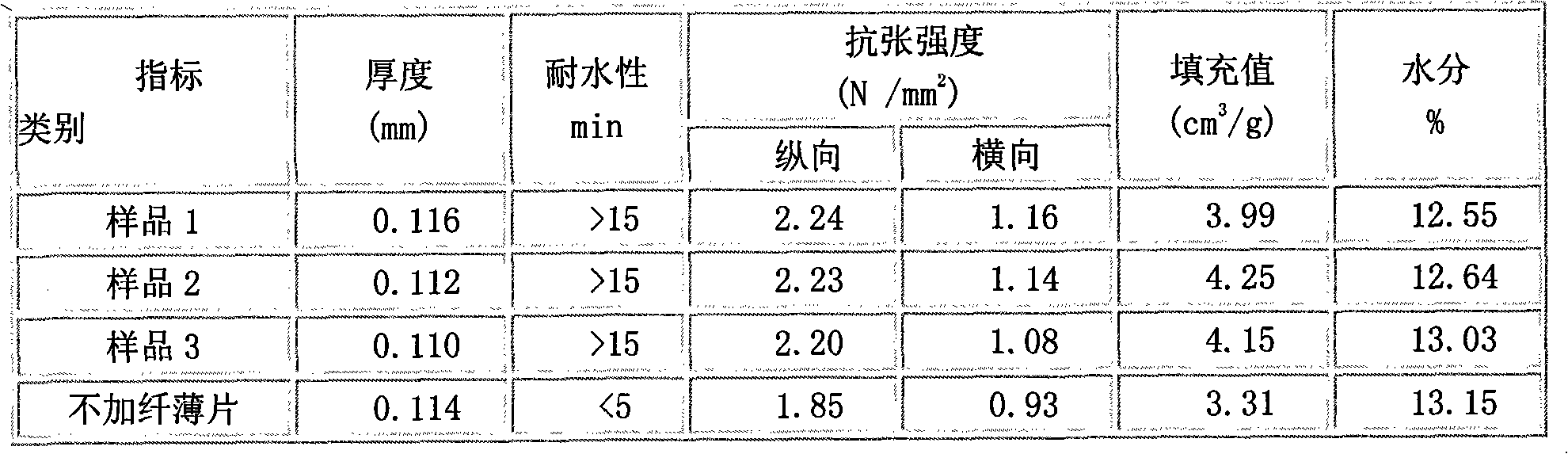

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

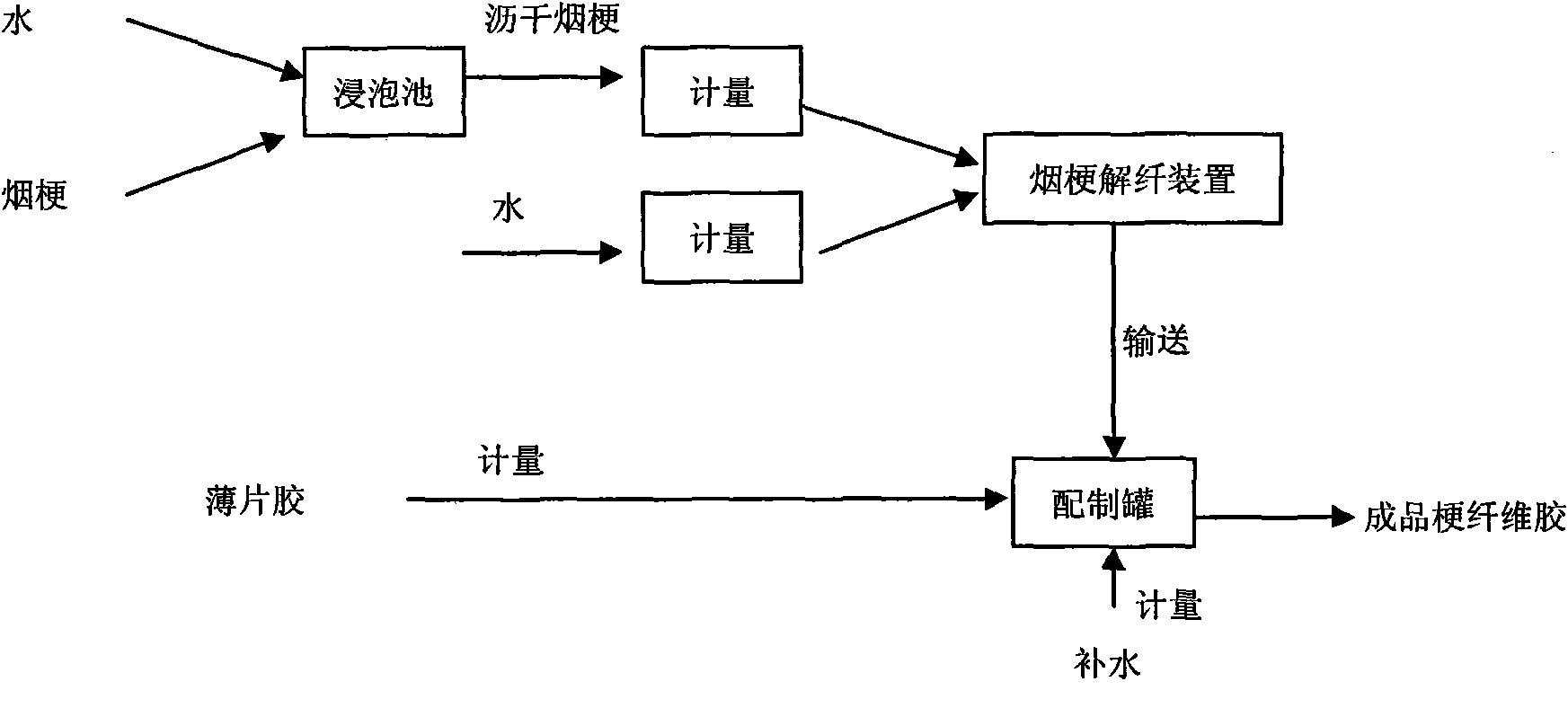

[0015] A process for defibrillating and fiberizing reconstituted tobacco leaves and stems by roll pressing, characterized in that it comprises the following steps:

[0016] a) Add the tobacco stems from which impurities have been removed into the immersion tank, add an appropriate amount of water to soak for 24 to 36 hours, remove and drain until it is anhydrous and analyzed in a natural state;

[0017] b) placing the drained tobacco stems and water in the tank of special tobacco stem defibrating equipment according to the weight ratio of 1:2-3 to defibrate for 10-30 minutes to obtain a suspended fiber liquid with uniform thickness and length;

[0018] c) mixing the fiber liquid obtained in step b and the sheet glue according to a mass ratio of 1:1 to 1.5 to form a tobacco stem plus fiber glue;

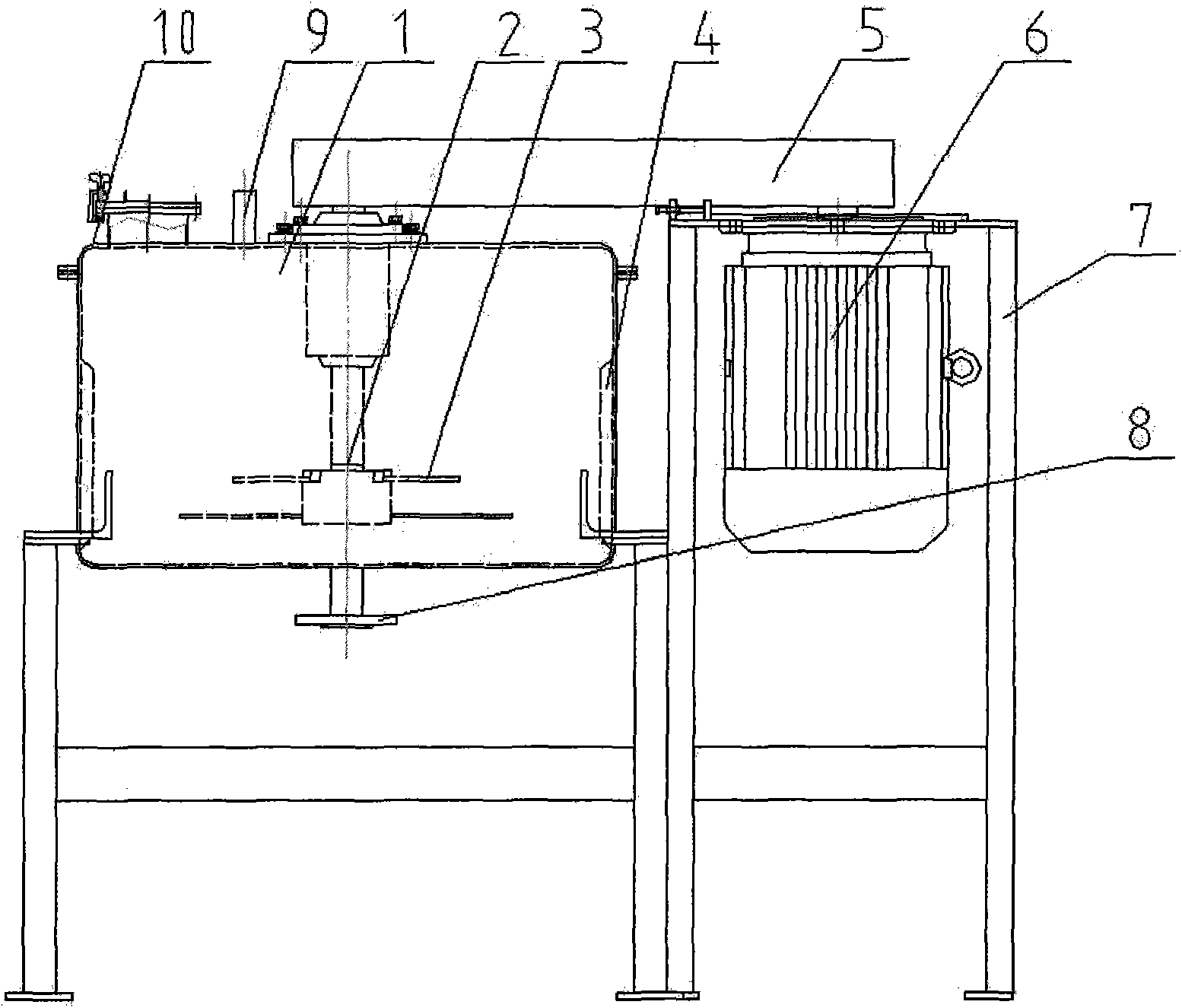

[0019] In order to realize the above process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com