Expansive well drilling pile grouting equipment with wide adaptability

An expanded and adaptable technology, applied to drilling equipment, drilling equipment and methods, drill bits, etc., can solve problems such as poor applicability, difficulty in pile filling operations, poor safety and reliability, etc., achieve force balance and improve equipment utilization , Guarantee the effect of stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

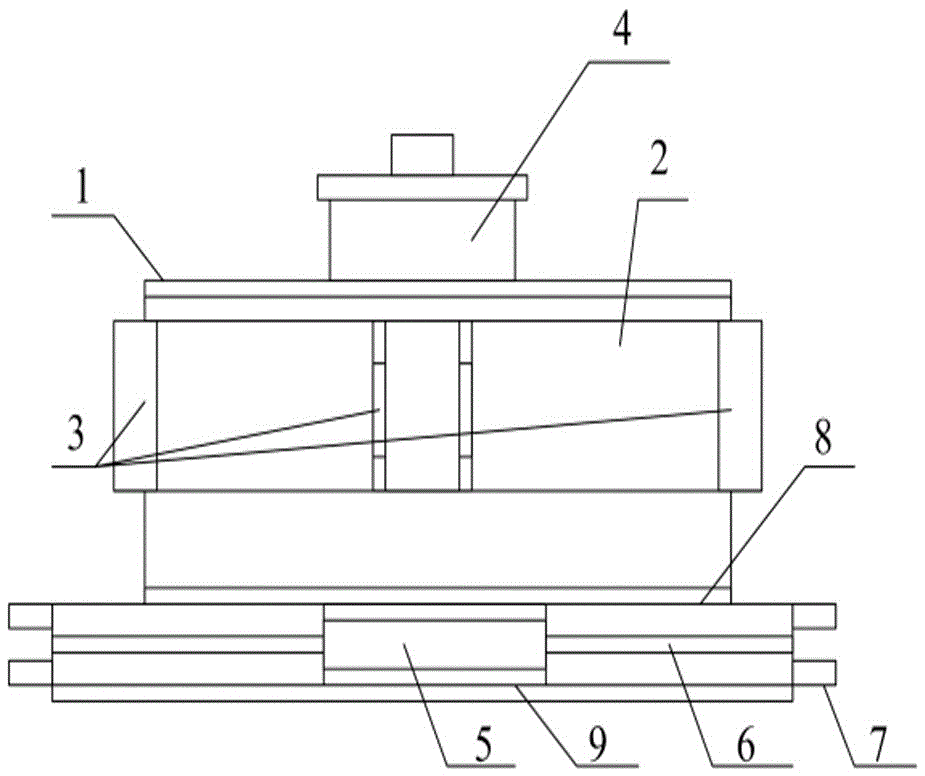

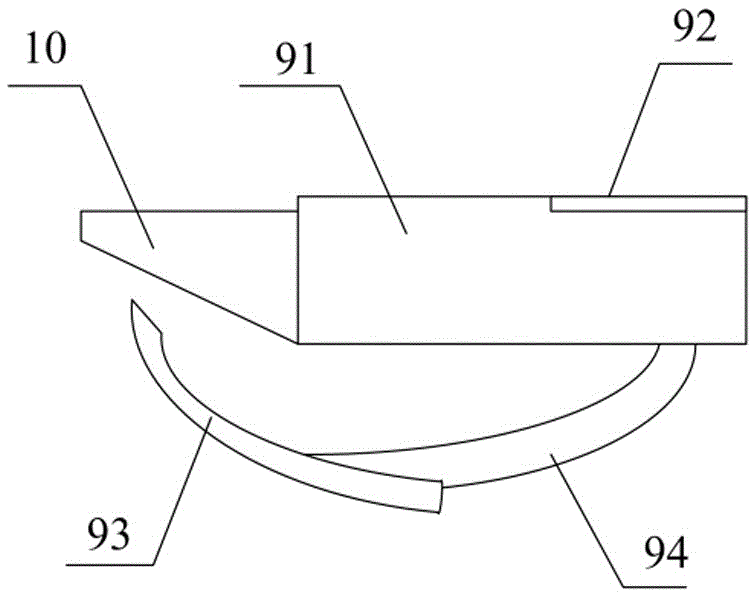

[0025] as attached figure 1 To attach figure 2 shown

[0026] The present invention provides extensive adaptability extended drilling pile filling equipment, including an expansion table 1, a machine body 2, a friction plate 3, a driving mechanism 4, a hydraulic cylinder 5, a piston rod 6, a drilling head 7, an inner cylinder 8 and an expansion arm 9, The expansion table 1 is arranged on the upper part of the body 2; the friction plate 3 is installed on the outside of the body 2; the driving mechanism 4 is connected to the top of the body 2; the hydraulic cylinder 5 is connected to the piston rod 6 on the outside The drill head 7 is installed on the outside of the expansion arm 9; the hydraulic cylinder 5 is installed on the inner lower part of the inner cylinder 8; the expansion arm 9 includes a groove plate 91, a notch 92, a crank 93 and a support plate 94, the upper side of the slot plate 91 is provided with a notch 92; the crank 93 is connected with the support plate 94...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com