Thermal ampoule for sprinkler

A technology of thermal glass tube and sprinkler head, which is applied in the direction of sprinkler with movable outlet, injection device, fire protection equipment, etc., can solve the problems of slow response, impossible to prevent fire expansion, difficult to prevent corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

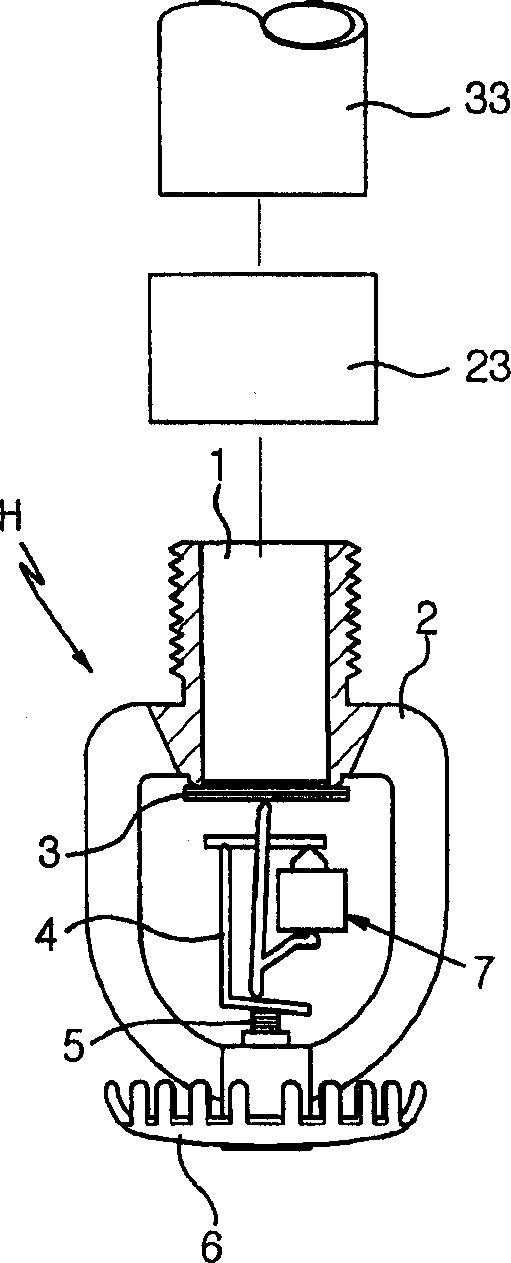

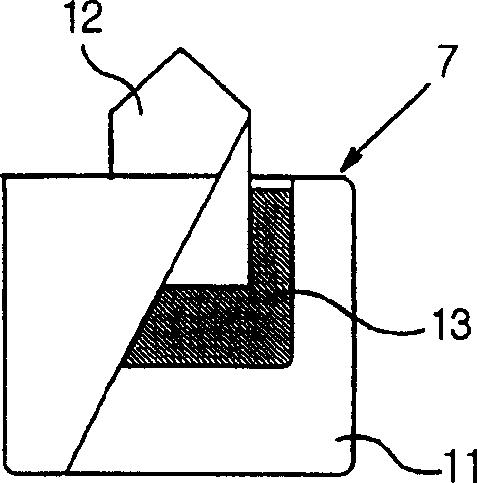

[0038] Figure 11 A schematic view showing the structure of a shower head equipped with a glass glass tube according to the present invention; Figure 12 is a partially cut-away sectional view of a glass tube according to the present invention; Figure 13 is a plan view of a glass tube according to the present invention; Figure 14 for along Figure 12 Sectional view taken on line 14-14 in ; and Figure 15 is a partially enlarged cross-sectional view of a shower head equipped with glass tubes according to the present invention. As shown in these figures, the glass tube 200 for a shower head according to the present invention is made of a conventional glass tube with a gas expanded by heat inside, but inside it, a new element of an electric heating coil is installed. According to the glass tube 200 used for the shower head of the present invention, it comprises: a closed hollow cylindrical glass shell 100; an electric heating coil 120 installed in the glass shell; a negati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com