High-performance micro-expansive grouting binder

A micro-expansion and binder technology, which is applied in the field of building materials, can solve the problems of low concrete bond strength, easy delamination and bleeding, and slow strength growth, and achieve the effects of reducing the probability of water permeability, improving water permeability, and increasing compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 A combination of high-performance micro-expansion grouting ratio is as follows

[0043] High Belite sulfoaluminate cement 35 parts

[0044] Heavy calcium 5 parts,

[0045] 3 parts mineral admixture,

[0046] Rheological preservative 3 parts

[0047] 6 parts of expansion agent,

[0048] 45 parts of quartz sand,

[0049] 1 part of water reducing agent,

[0050] 0.5 part of retarder,

[0051] 0.1 part of water retaining agent,

[0052] 0.2 parts of early strength agent,

[0053] Shrinkage reducer 0.2 part,

[0054] Thixotropic lubricant 0.2 parts

[0055] Redispersible latex powder 0.3 parts,

[0056] 0.2 part of defoamer,

[0057] Hydrophobic agent 0.1 parts

Embodiment 2

[0058] Example 2 A combination of high-performance micro-expansion grouting ratio is as follows

[0059] High Belite sulphoaluminate cement 38 parts

[0060] Heavy calcium 8 parts,

[0061] 4 parts mineral admixture,

[0062] Rheological preservative 5 parts

[0063] 6 parts of expansion agent,

[0064] 35 parts of quartz sand,

[0065] 2 parts of water reducing agent,

[0066] 0.5 part of retarder,

[0067] 0.3 parts of water retaining agent,

[0068] 0.4 parts of early strength agent,

[0069] Shrinkage reducer 0.3 parts,

[0070] Thixotropic lubricant 0.1 part

[0071] Redispersible latex powder 0.1 parts,

[0072] 0.1 part of defoamer,

[0073] Hydrophobic agent 0.2 parts

Embodiment 3

[0074] Example 3 A combination of high-performance micro-expansion grouting ratio is as follows

[0075] High Belite sulfoaluminate cement 45 parts

[0076] Heavy calcium 5 parts,

[0077] 4 parts mineral admixture,

[0078] Rheological preservative 3 parts

[0079] 4 parts of expansion agent,

[0080] 35 parts of quartz sand,

[0081] 1.5 parts of water reducer,

[0082] 1.5 parts of retarder,

[0083] 0.2 parts of water retaining agent,

[0084] 0.4 parts of early strength agent,

[0085] Shrinkage reducer 0.3 part,

[0086] Thixotropic lubricant 0.1 parts

[0087] Redispersible latex powder 0.3 part,

[0088] 0.2 part of defoamer,

[0089] Hydrophobic agent 0.2 parts

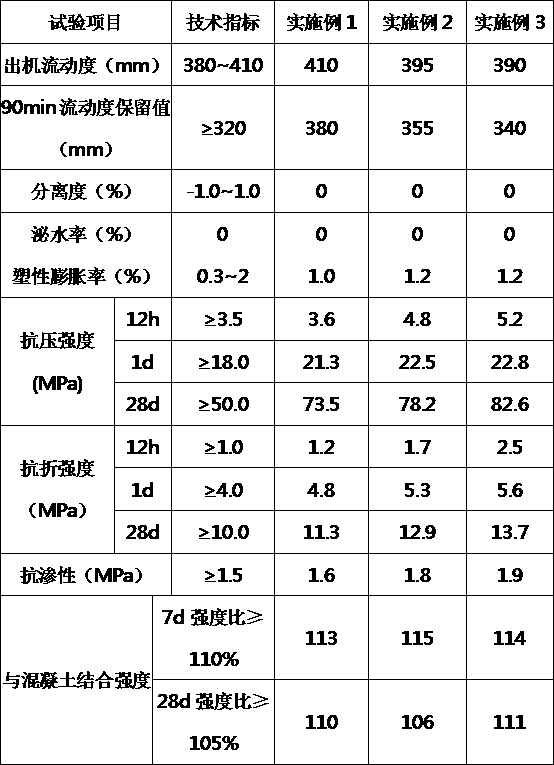

[0090] According to the test method described in the "Temporary Requirements for Grouting with Formwork in Tunnels", the technical performance of the binder in each example is measured by using a water-to-material ratio of 0.18 as shown in the table below:

[0091]

[0092] It can be seen from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| impermeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com