Brushless DC-motor sliding-mode control system used for metro shielding barriers

A brushed DC motor and control system technology, applied in the direction of a single motor speed/torque control, electronic commutator, etc., can solve the problems of difficulty in reaching the optimal state, dependence, poor robustness, etc., and improve the response speed and reduce the speed. Chattering, robustness-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

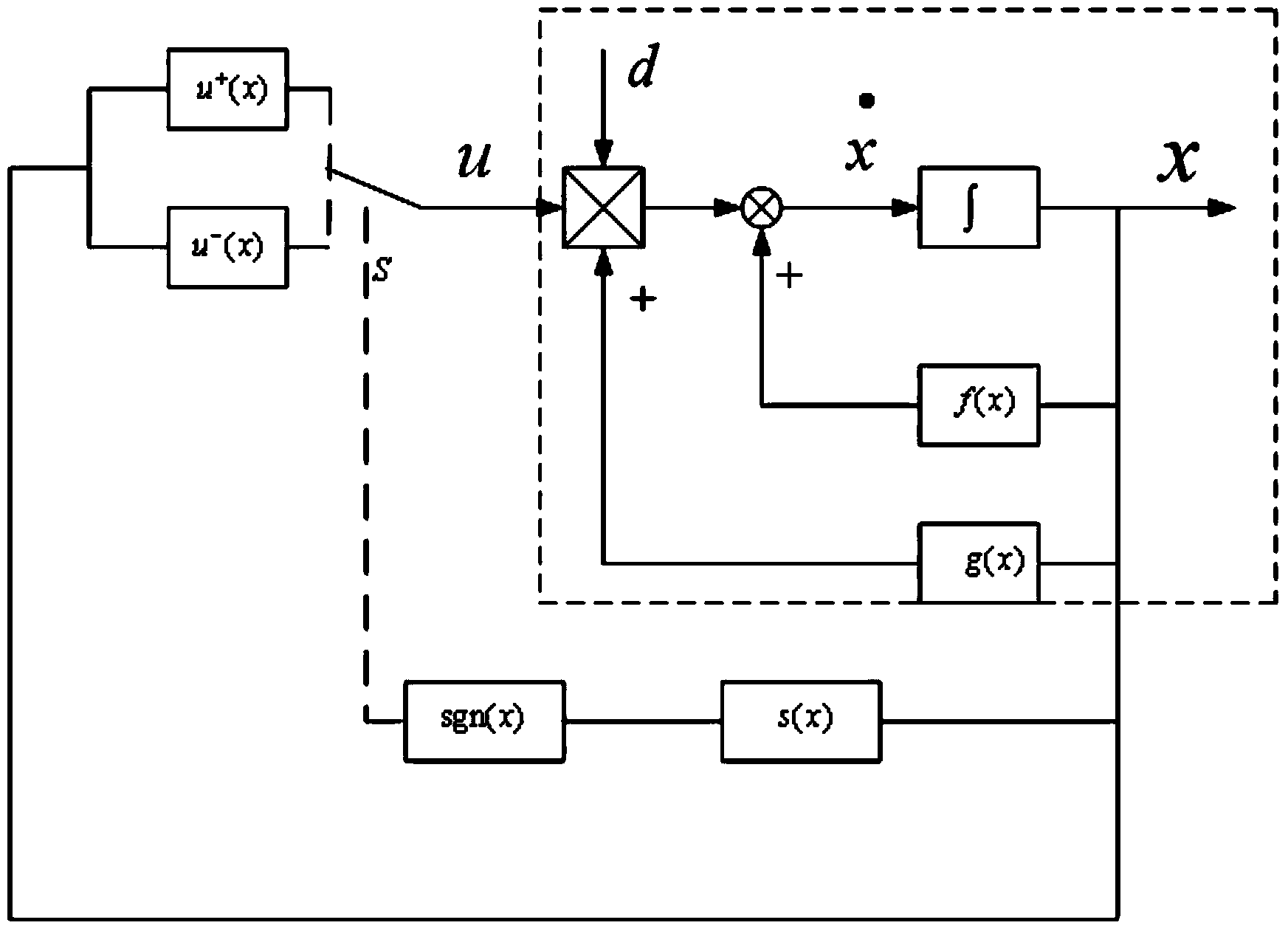

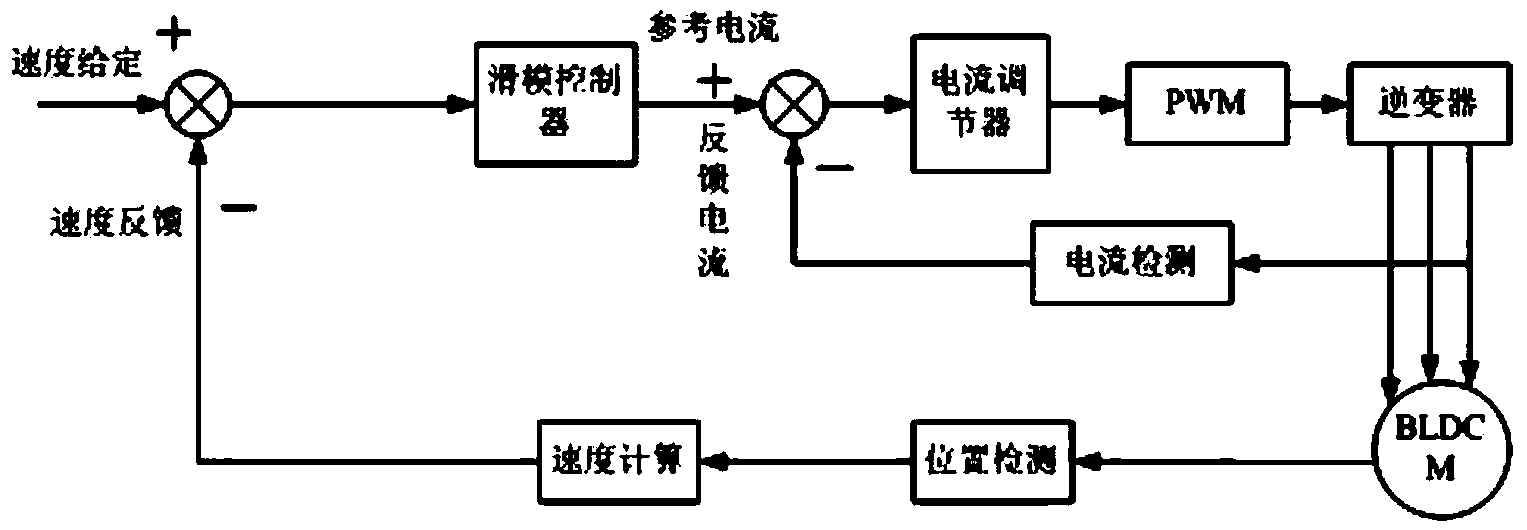

[0011] In view of the above-mentioned defects, the present invention provides a brushless DC motor sliding mode control system for subway screen doors. The control algorithm is simple, the response speed is fast, it is insensitive to parameter changes and disturbances, and does not require system online identification.

[0012] For realizing the above object, technical scheme of the present invention is:

[0013] A brushless DC motor sliding mode control system for subway screen doors, which consists of a sliding mode variable structure controller, a current detection module, a current regulation module, a PWM module, an inverter module, a brushless DC motor BLDCM, and a speed calculation module It is composed of a position detection device; double closed-loop control is adopted, that is, the speed loop is used as the outer loop, and the position detection module is sent to the speed calculation module to realize the speed calculation. The calculated speed is compared with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com