Brushless DC motor control device and control method therefor

A brushed DC motor and control method technology, which is applied in the direction of AC motor control, DC motor speed/torque control, motor control, etc., can solve the problems of limiting the maximum power of the motor, not suitable for the miniaturized design of the motor, and rising manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

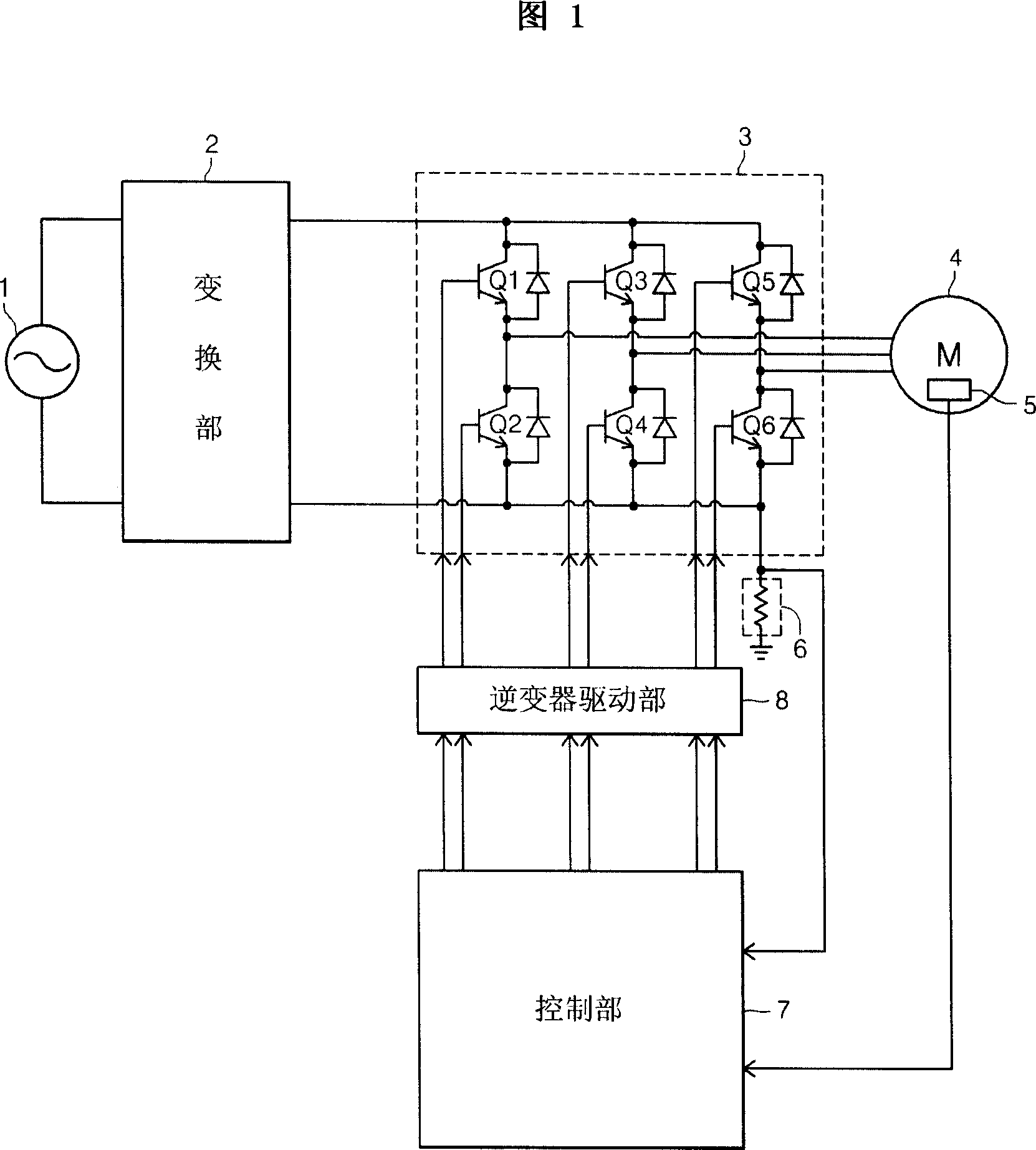

[0021] As shown in Figure 1, the control device of the brushless DC motor 4 provided according to the present invention includes: an AC power supply 1; a converter 2 for converting the AC power of the AC power supply 1 into DC power; The inverter 3 that converts the DC power of the device 2 into AC power; the brushless DC motor 4 driven by the inverter 3; the current detection part 6 for detecting the load current of the brushless DC motor 4; The inverter driving part 8 of the inverter 3; the control part 7 controls the inverter by outputting a control signal for controlling the rotation speed of the brushless DC motor 4 to the inverter driving part 8 according to the current value detected by the current detecting part 6. Transformer.

[0022] The inverter 3 is composed of a plurality of transistors (Q1 to Q6), and the plurality of transistors (Q1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com