A brushless DC motor controlling method

A technology of DC motor and control method, which is applied in the direction of electronic commutation motor control, single motor speed/torque control, control system, etc. , The effect of reducing torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below, refer to the attached figure 1 ~ attached Figure 7 Preferred embodiments of the present invention will be described in detail.

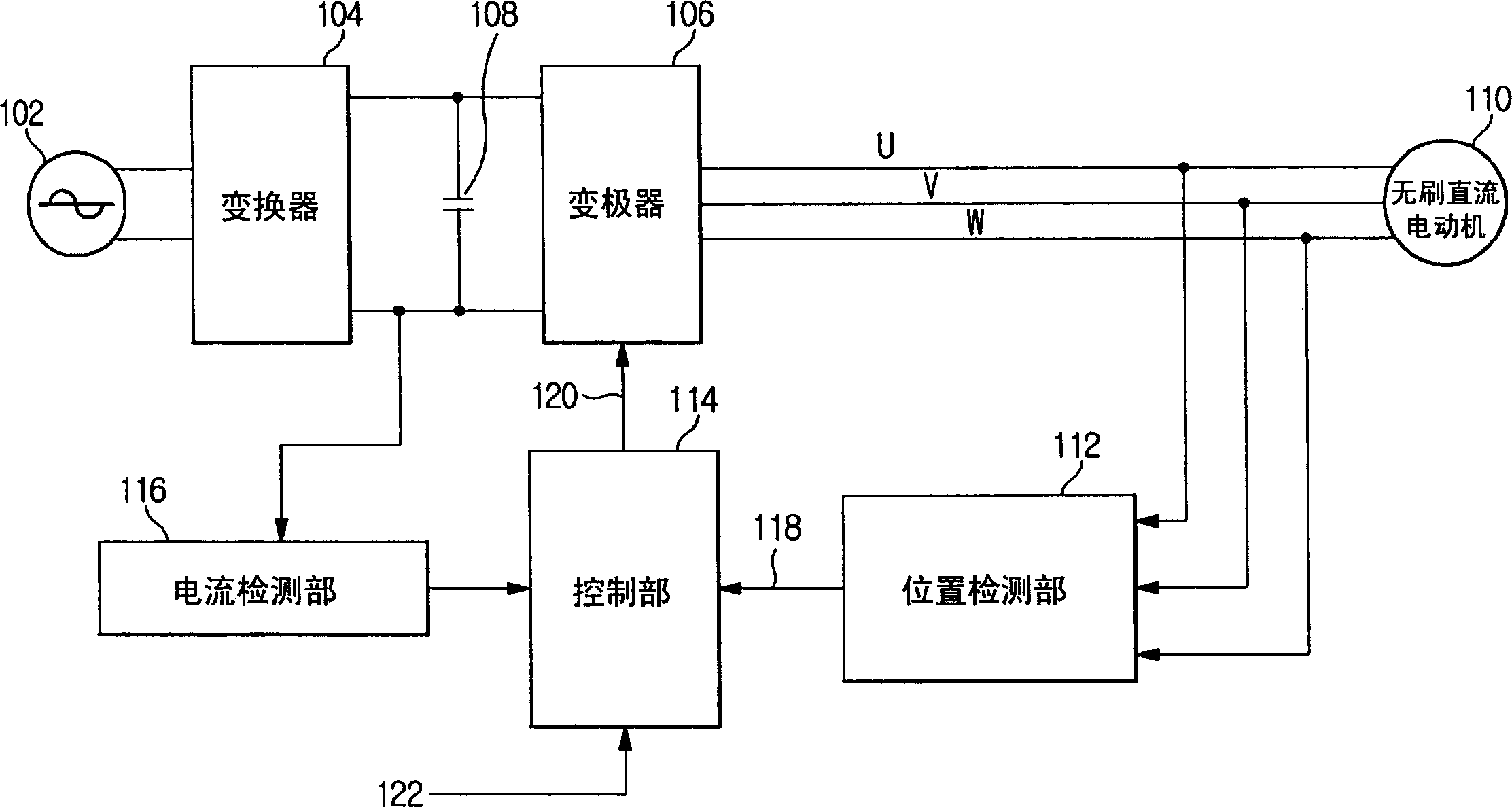

[0019] figure 1 It is a block diagram showing the control device of the brushless DC motor according to the embodiment of the present invention. Such as figure 1 As shown, the power conversion device composed of a converter (converter) 104, a capacitor 108 and an inverter (inverter) 106 converts the AC power provided by the AC power supply device 102 into a pulsed 3-phase AC power supply to the brushless DC motor 110. The position detection unit 112 acquires rotor position information from the three-phase AC power supply (U, V, W) supplied to the brushless DC motor 110 by the inverter 106 to generate a position detection signal 118 . The position detection signal 118 of the position detection part 112 is supplied to the control part 114, and the inverter control signal 120 is generated based on this position detection signal 118. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com