Halogen-free high-impedance water-based washing-free scaling powder as well as preparation method and application thereof

A flux and high-impedance technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve problems such as component pin short circuit, component failure, etc., and achieve good matching, safe use, and excellent electrical insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

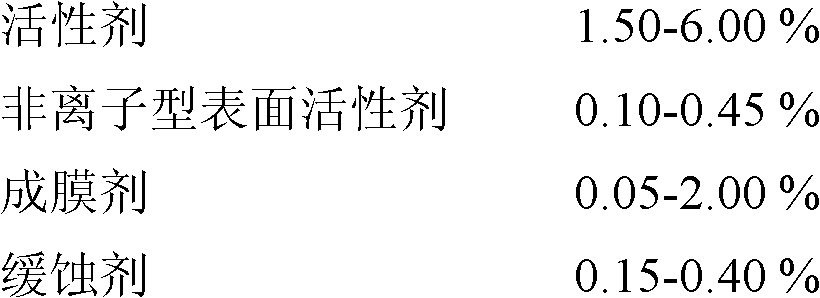

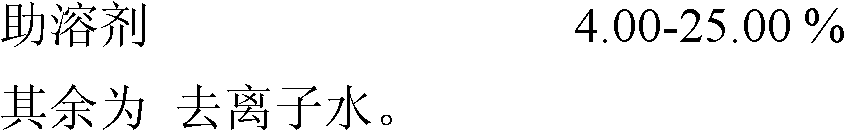

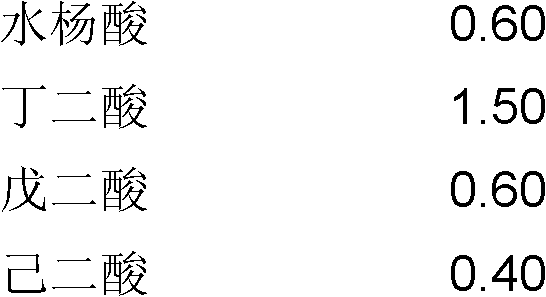

[0023]

[0024]

[0025] Preparation method: add deionized water into a clean reaction kettle with a stirring device at room temperature, start stirring after the co-solvent is added, add active agent and non-ionic surfactant, stir for 20 minutes, then add film-forming agent and stir for 20 minutes, Then add other raw materials, continue to stir until the solid raw materials are completely dissolved, then stop stirring, let stand and filter to obtain the product.

[0026] The method of using the halogen-free high-impedance water-based no-cleaning flux of the present invention: the flux can be evenly coated on the PCB board by spraying, foaming, dipping and other methods, and the PCB board is preheated, and the preheating temperature is 95 ℃-120℃ (measured on the top of the board), the deionized water in the flux is completely evaporated, and then soldered in a single-wave or double-wave soldering solder tank. The solder temperature depends on the type of lead-free solder,...

Embodiment 2

[0028]

[0029] The preparation and use methods are the same as in Example 1.

Embodiment 3

[0031]

[0032]

[0033] The preparation and use methods are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com