Constant-temperature electroplating rinsing bath and constant-temperature aluminum alloy electroplating technology

A water washing tank and constant temperature technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of difficult to achieve cooling effect, poor binding force, high quality cost, etc., and achieve the solution of poor binding force and oxidation of the deposited zinc layer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

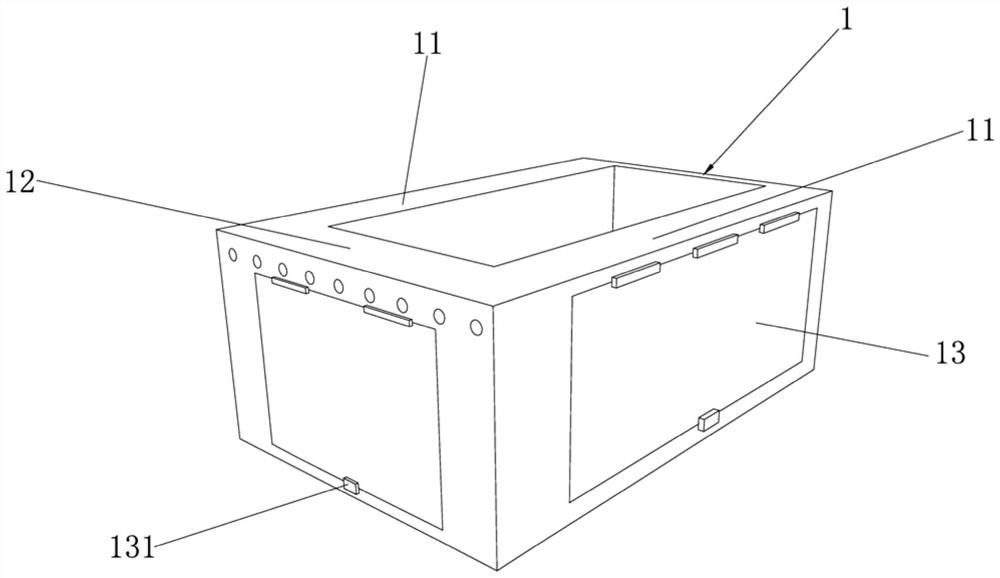

[0024]Appendfigure 1As shown, a constant temperature electro-plated water washing tank, including a tank body 1, and a heat exchange chamber 11 for accommodating a constant temperature device is provided on both sides of the tank body 1, and the other side of the tank body. One side of the upper part is provided with a motor chamber 12 for accommodating a compression motor that provides power to the constant temperature device, and the heat exchange chamber 11 is covered with the motor chamber 12, which is covered with open inspection door 13, The detecting gate 13 has a lock 131 that is locked with a groove body, which is a thermally conductive material, and the inspection gate 13 is an insulated material.

[0025]The corresponding thermostatic apparatus is provided in each of the thermal exchange chambers 11, each set of thermostats, including a heat-washing temperature controlling the water-washing temperature of 10-25 ° C in the tank.

[0026]A constant temperature aluminum alloy elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com