Novel environment-friendly soldering flux for low-silver SnAgCu unleaded soldering paste

A lead-free solder paste, environmentally friendly technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., to achieve good activity, long storage and service life, and less residue after welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

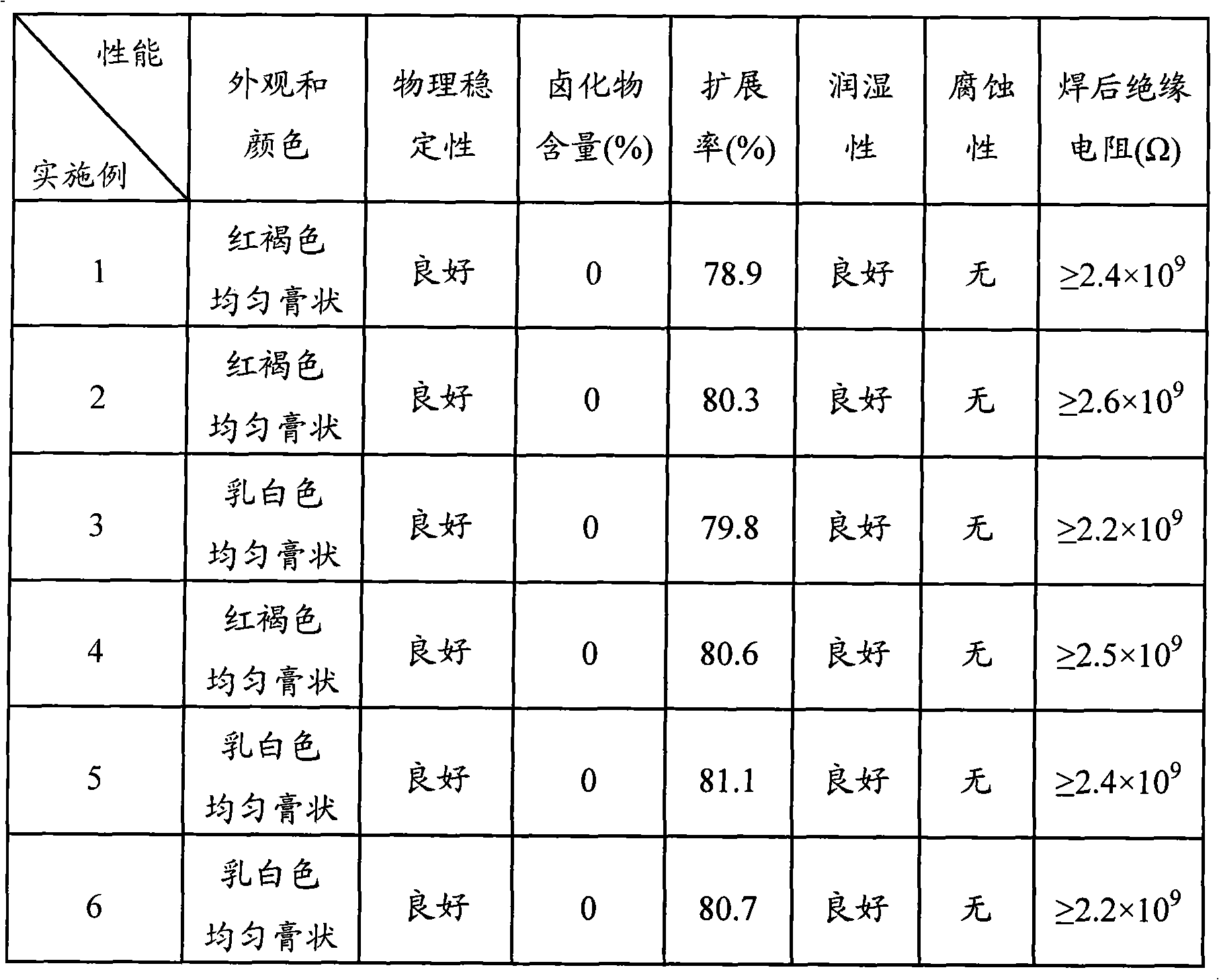

Examples

Embodiment 1

[0030] The active agents selected are succinic acid, salicylic acid and DL-malic acid, the solvent is glycerol and diethylene glycol monoethyl ether, the corrosion inhibitor is triethylamine, the thixotropic agent is hydrogenated castor oil, and the ointment is polyethylene glycol. Ethylene glycol 1000, the stabilizer is paraffin, the surfactant is octylphenol polyoxyethylene ether, and the modified rosin is polymerized rosin and hydrogenated rosin; the mass percentage (wt %) of each component is:

[0031] Succinic acid 1.5

[0032] Salicylic acid 1.5

[0033] DL-Malic Acid 2.0

[0034] Glycerol 14.0

[0035] Diethylene glycol monoethyl ether 18.0

[0036] Triethylamine 0.8

[0037] Hydrogenated castor oil 4.2

[0038] Polyethylene glycol 1000 6.0

[0039] Paraffin 2.5

[0040] Octylphenol ethoxylate 3.5

[0041] polymerized rosin 24.0

[0042] Hydrogenated rosin 22.0

Embodiment 2

[0044] The active agents selected are glutaric acid, salicylic acid and citric acid, the solvents are diethylene glycol and diethylene glycol monobutyl ether, the corrosion inhibitor is triethanolamine, the thixotropic agent is hydrogenated castor oil, and the ointment is polyethylene glycol. Alcohol 1000, stabilizer is paraffin, surfactant is octylphenol polyoxyethylene ether, and modified rosin is polymerized rosin and water-white rosin; the mass percentage (wt %) of each component is:

[0045] Glutaric acid 2.0

[0046] Salicylic acid 2.5

[0047] Citric acid 3.0

[0048] Diethylene glycol 18.0

[0049] Diethylene glycol monobutyl ether 18.0

[0050] Triethanolamine 1.5

[0051] Hydrogenated Castor Oil 1.0

[0052] Polyethylene glycol 1000 4.4

[0053] Paraffin 0.3

[0054]Octylphenol ethoxylate 1.3

[0055] polymerized rosin 24.0

[0056] Water white rosin 24.0

Embodiment 3

[0058] The active agents selected are adipic acid, succinic acid and DL-malic acid, the solvents are glycerol and ethylene glycol monomethyl ether, the corrosion inhibitors are triethylamine and triethanolamine, and the thixotropic agent is hydrogenated castor oil. The ointment is polyethylene glycol 2000, the stabilizer is paraffin, the surfactant is isooctylphenol polyoxyethylene ether, and the modified rosin is perhydrogenated rosin and water-white rosin; the mass percentage (wt%) of each component for:

[0059] Adipic acid 1.5

[0060] Succinic acid 3.0

[0061] DL-malic acid 4.5

[0062] Glycerol 16.0

[0063] Ethylene glycol monomethyl ether 20.0

[0064] Triethylamine 3.0

[0065] Triethanolamine 2.0

[0066] Hydrogenated Castor Oil 6.0

[0067] Polyethylene glycol 2000 2.0

[0068] Paraffin 1.0

[0069] Isooctylphenol ethoxylate 1.0

[0070] Fully hydrogenated rosin 20.0

[0071] Water white rosin 20.0

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com