Vacuum eutectic welding method

A technology of vacuum eutectic welding and eutectic furnace, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of low heating efficiency, accelerated chip, failure, etc., achieve low cost, avoid chip over-soldering, The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The method adopted in this embodiment is:

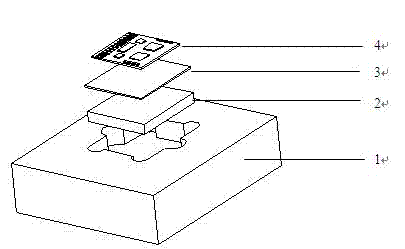

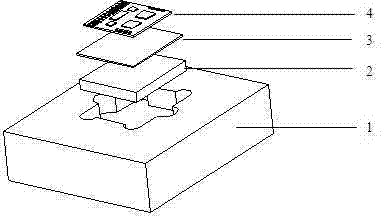

[0028] 1. Design and process a kind of tooling. The material of the tooling is high-purity graphite plate. Several square grooves are milled on the graphite plate, and two semicircular grooves are milled on a group of opposite sides of the square grooves, which are used for taking and placing heat sinks, preheating Forming solder sheets and chips;

[0029] 2. Clean the graphite tooling and install it into the process chamber of the vacuum eutectic furnace;

[0030] 3. Clean the heat sink and preformed solder sheet;

[0031] 4. Put the heat sink, preformed solder sheet and chip into the square groove of the graphite tooling in turn;

[0032] 5. Close the cover plate of the process chamber of the vacuum eutectic furnace;

[0033] 6. The process chamber is vacuumed, filled with nitrogen, and then vacuumed again, and the oxygen and water vapor in the chamber are removed by repeated vacuuming and nitrogen filling, and the atmosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com