Cast-welding production device of accumulator and production process thereof

A technology for production devices and storage batteries, which is applied to secondary batteries, electrochemical generators, circuits, etc., can solve the problems of environmental pollution and human injury, high scrapping and repair welding rates, uneven appearance of casting and welding, etc., and saves money. Time and production cost, low scrap and repair welding rate, reducing environmental pollution and harm to human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

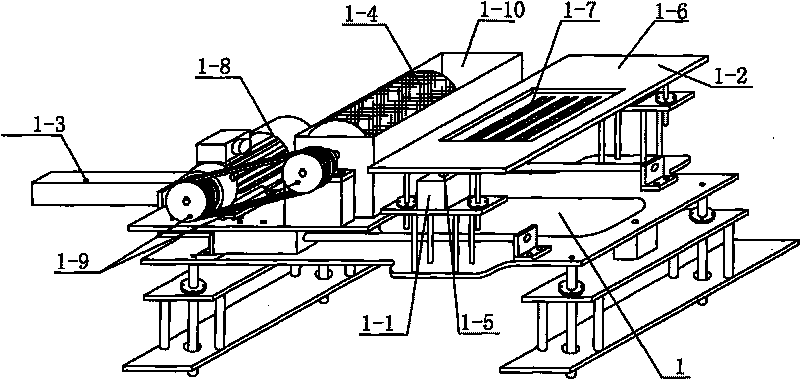

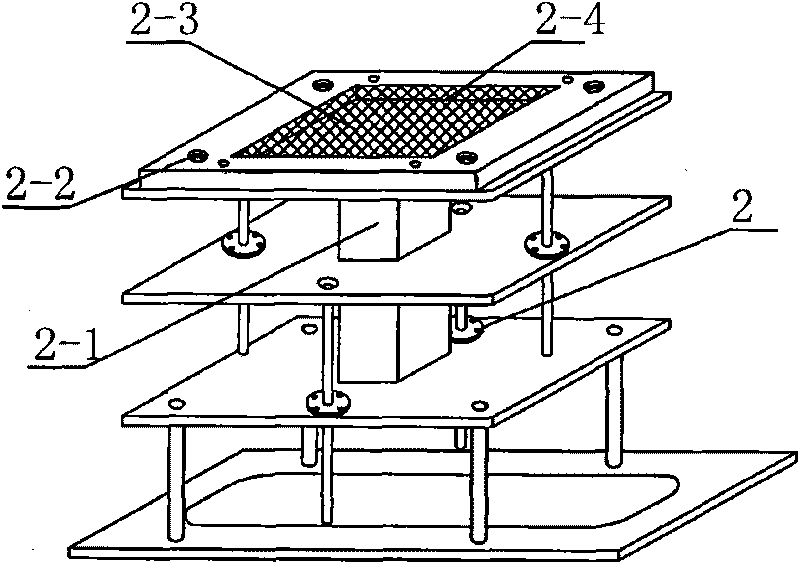

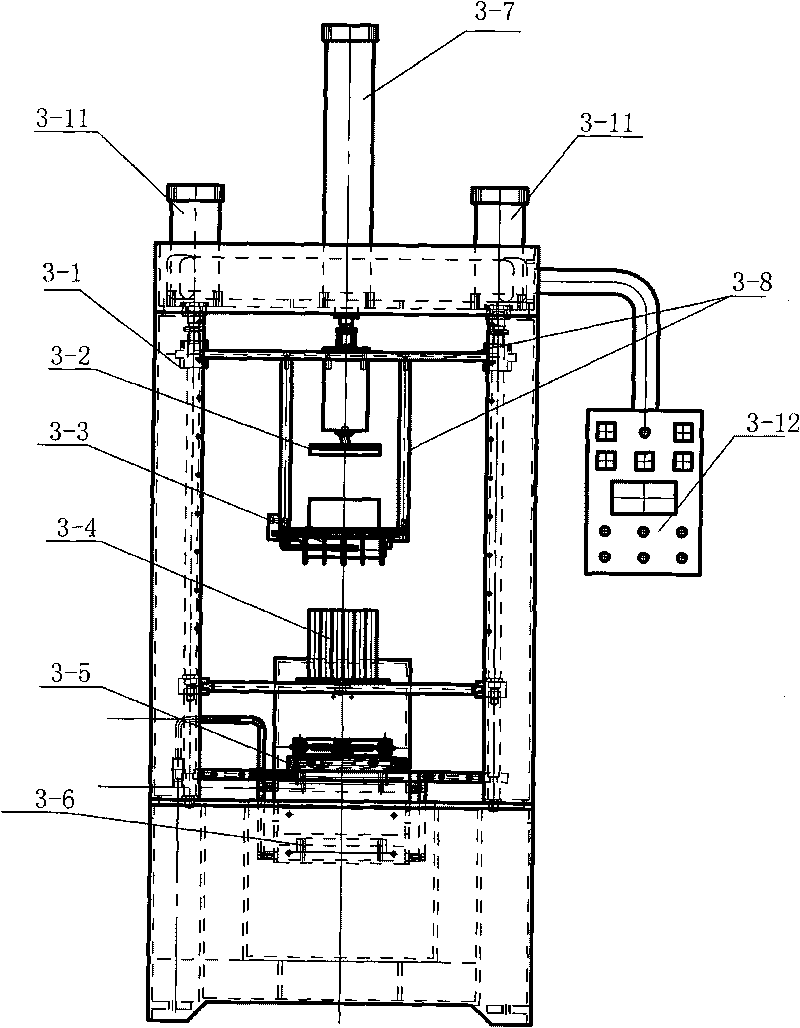

[0013] Such as Figure 1~4 As shown: it includes a brushing device 1, a dipping device 2, a casting and welding host 3, the brushing device, and the dipping device are sequentially connected through a battery transmission line.

[0014] The brush device includes a brush main board 1-2 with an ejecting cylinder 1-1, a wire brush 1-4 with a brush cylinder 1-3, and the brush main board is placed horizontally on the front end of the brush device. The bottom of the brush main board is provided with an ejecting cylinder, and the support rods 1-5 of the ejecting cylinder are connected to both sides of the brush main board, and a brush net plate 1-6 is arranged in the middle of the brush main board, and the brush net board Through holes 1-7 are distributed, and a wire brush is arranged behind the main board of the brush. Also be provided with motor 1-8 on the sheet cylinder, wire brush is connected with motor by belt pulley 1-9. When the battery plate is transported to the brush pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com