Automatic sleeve penetrating device

An automatic casing threading and casing threading technology, which is applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of low work efficiency, inability to automatically thread casings, increase labor, production costs and processing time and other problems to achieve the effect of high work efficiency, labor saving and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

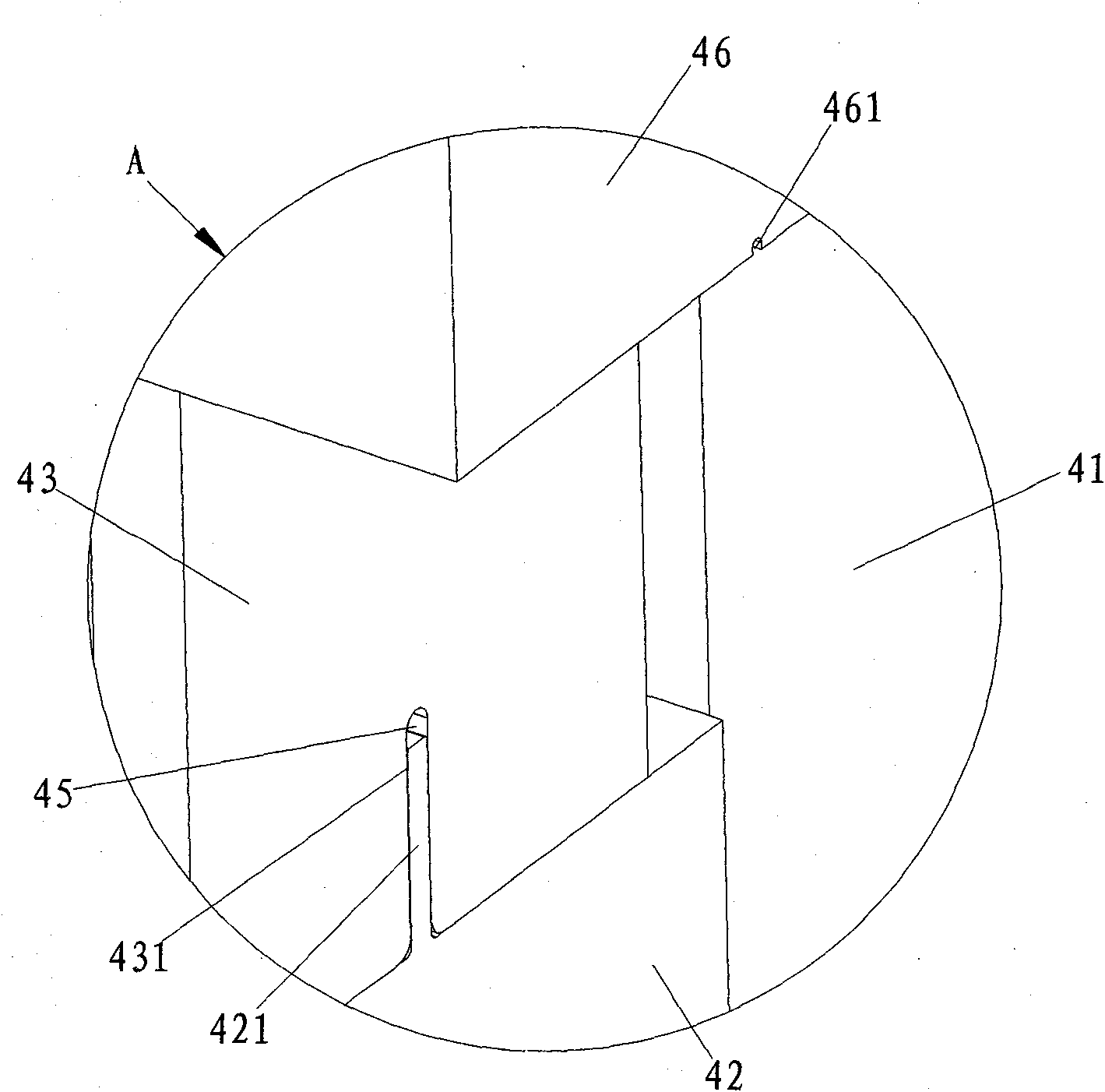

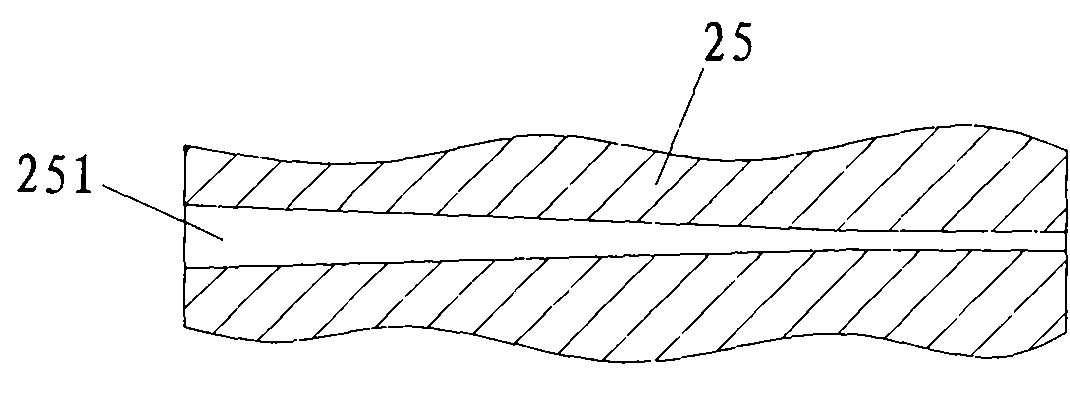

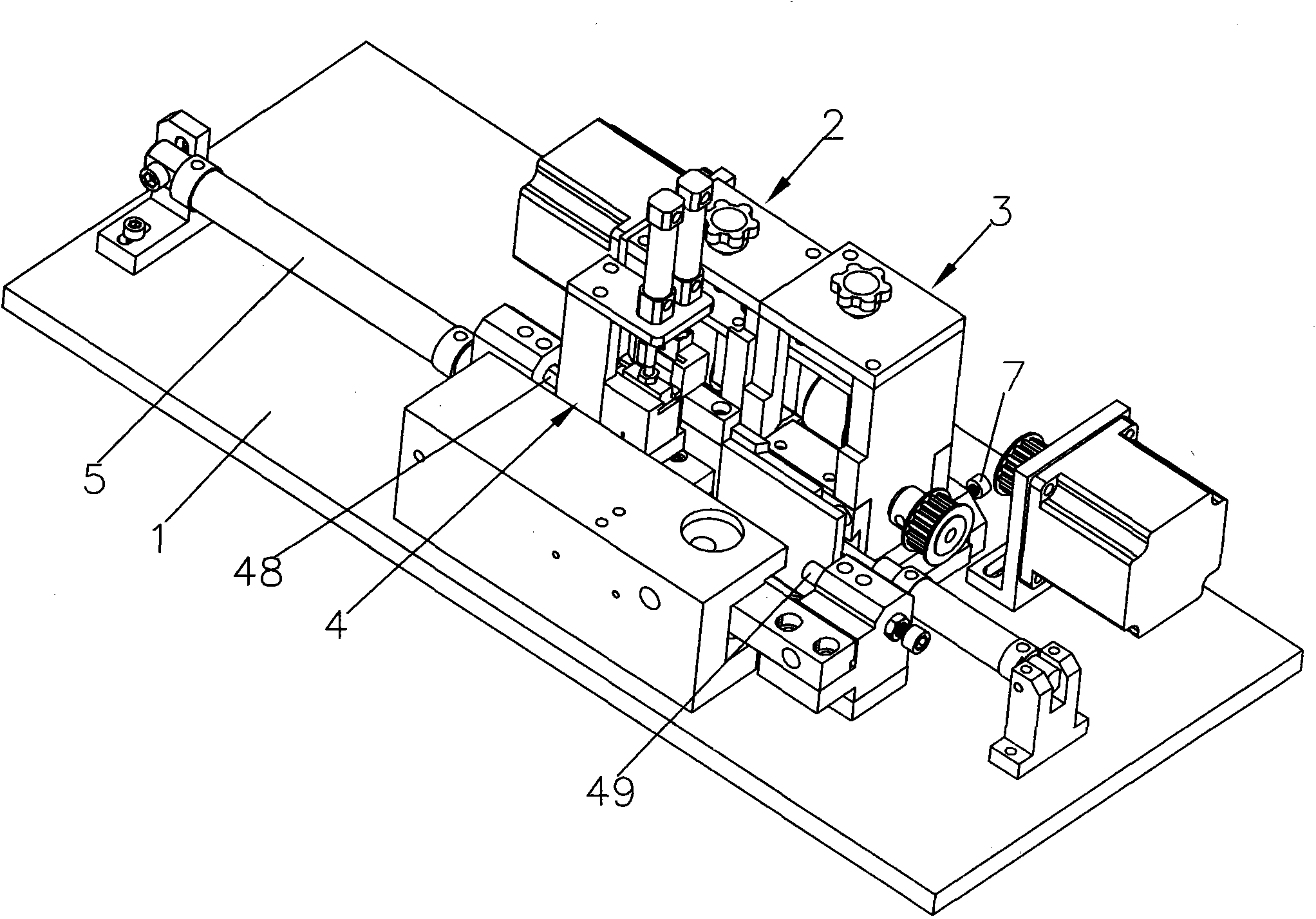

[0024] Below in conjunction with accompanying drawing, the present invention will be further described, see Figure 1-8 As shown, the present invention includes a welding workbench 1, and the welding workbench 1 is provided with a casing threading device 2 for conveying the casing, a copper wire threading device 3 for conveying copper wires, and a casing clamp for outputting the casing threading device 2 Jacketed pipe device 4, the casing moving cylinder 5 that pushes the jacketed pipe device 4 to move between the casing pipe device 2 and the copper wire device 3, the linear slide rail 6, the jacket pipe device 4 and the linear slide rail 6 is slidingly connected, and the output end of the sleeve pipe moving cylinder 5 is connected with the jacket pipe device 4. The linear slide rail 6 ensures that the jacketed pipe device 4 is stable during movement, with small gaps and small resistance, so that the jacketed pipe device 4 slides normally and stably.

[0025] The casing threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com