Technique for producing acetylene gas by dry method

An acetylene gas and process technology, which is applied in the field of dry production of acetylene gas, can solve problems such as dissolution loss, and achieve the effects of reducing drying, high yield and reducing equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

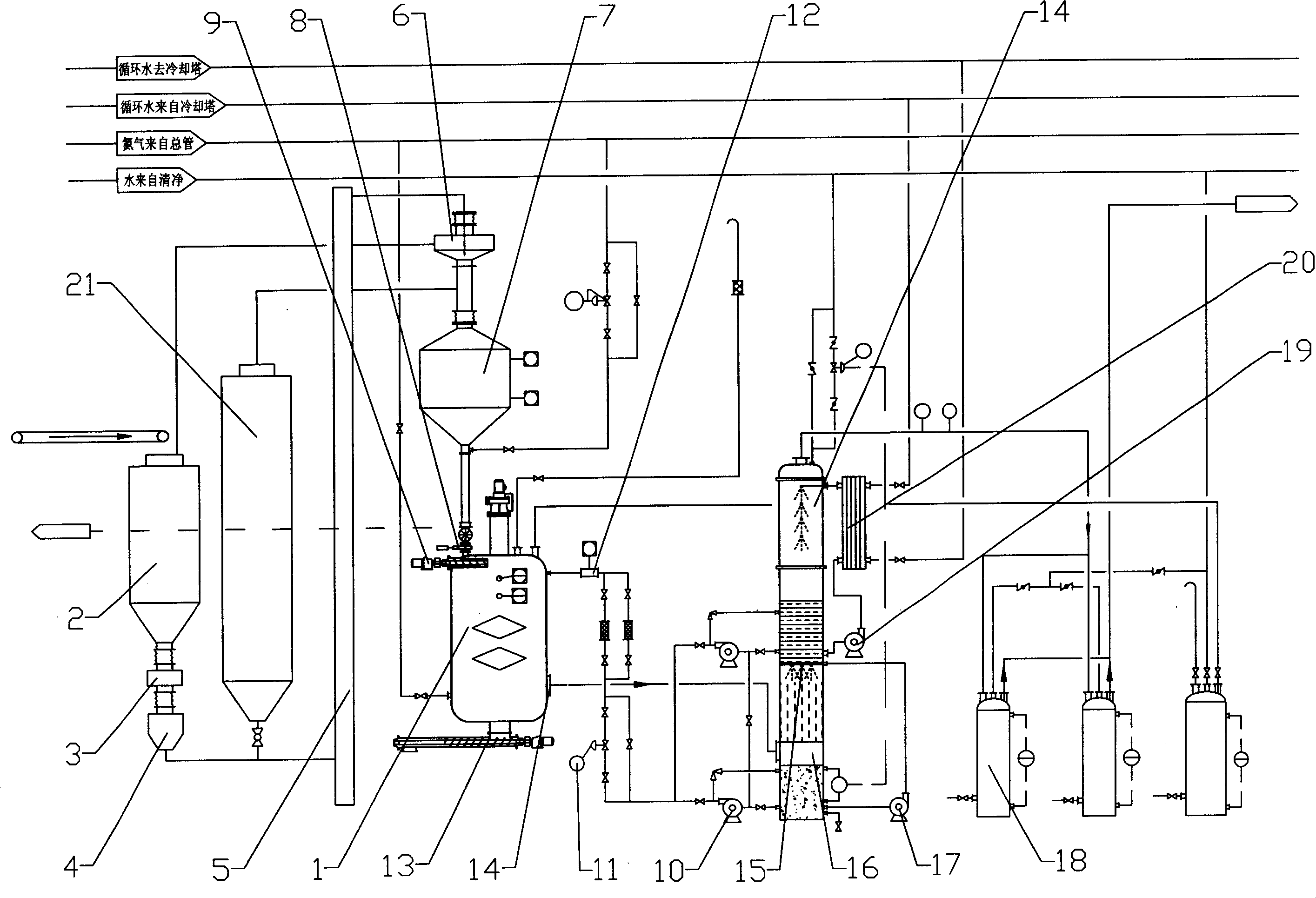

[0031] Embodiment 1, a kind of technique of dry method production acetylene gas, production technique comprises the following steps:

[0032] a. After rough crushing and fine crushing, the massive calcium carbide becomes particles with a particle size of less than 70mm, and then after electromagnetic iron removal, it is transported to the coarse material bin 2 by a belt conveyor;

[0033] b. The calcium carbide particles in the coarse feeder 2 are sent to the crusher 4 for pulverization through the centrifugal feeder 3, and the calcium carbide particles are pulverized, and the crushed calcium carbide particles are transported to the rotary screen filter 6 through the bucket elevator 5 for filtration. Calcium carbide powder less than 7mm after filtering enters the silo 7. When the silo 7 is full, the calcium carbide powder overflows to the fine silo 21, and the calcium carbide powder in the fine silo 21 enters through the bucket elevator 5 and the rotary sieve filter 6. The cal...

Embodiment 2

[0041] Embodiment 2, a kind of technique of dry production acetylene gas, production technique comprises the following steps:

[0042] a. After coarse crushing and fine crushing, the massive calcium carbide becomes particles with a particle size of less than 50mm, and then after electromagnetic iron removal, it is transported to the coarse material bin 2 by a belt conveyor;

[0043] b. The calcium carbide particles in the coarse feeder 2 are sent to the crusher 4 for pulverization through the centrifugal feeder 3, and the calcium carbide particles are pulverized, and the crushed calcium carbide particles are transported to the rotary screen filter 6 through the bucket elevator 5 for filtration. Calcium carbide powder less than 3mm after filtering enters the silo 7. When the silo 7 is full, the calcium carbide powder overflows to the fine silo 21, and the calcium carbide powder in the fine silo 21 enters through the bucket elevator 5 and the rotary sieve filter 6. The calcium c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com