Synthesis method of dibutyltin dilaurate

A technology of dibutyltin cinnamate and dibutyltin dichloride, applied in the direction of tin organic compounds, etc., can solve problems such as environmental pollution, a large amount of waste water, unfavorable environment and human health, etc., to protect the environment and personal safety, shorten the process, and reduce energy. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

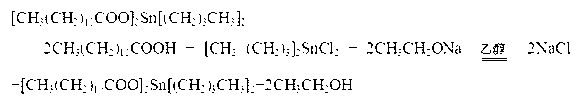

Image

Examples

Embodiment 1

[0018] A kind of synthetic method of dibutyltin dilaurate, comprising the following steps: (1) add 200g lauric acid, 123.3g dichloro Dibutyltin and 100mL of absolute ethanol, inject 226.6g of sodium ethoxide-ethanol solution with a mass fraction of 30% into the constant pressure dropping funnel, start heating and stirring, when the temperature of the mixed solution reaches 55°C, add the sodium ethoxide-ethanol solution dropwise , keep the dropping rate at 7mL / min;

[0019] (2) After the sodium ethoxide-ethanol solution is added dropwise, keep the temperature at 50-60°C. After reacting for 30 minutes, turn on the cooling water and start vacuuming to evaporate the ethanol solvent. When the temperature of the mixed solution in the reactor reaches 70 ℃, and when no liquid distills out, stop vacuuming and heating;

[0020] (3) Use a funnel to filter out the crystals in the feed liquid to obtain a light yellow liquid product.

Embodiment 2

[0022] A kind of synthetic method of dibutyltin dilaurate, comprising the following steps: (1) add 200g lauric acid, 123.3g dichloro Dibutyltin and 76mL of absolute ethanol, inject 226.6g of sodium ethoxide-ethanol solution with a mass fraction of 28% into the constant pressure dropping funnel, start heating and stirring, when the temperature of the mixed solution reaches 55°C, add the sodium ethoxide-ethanol solution dropwise , keep the dropping rate at 10mL / min;

[0023] (2) After the sodium ethoxide-ethanol solution is added dropwise, keep the temperature at 50-60°C. After reacting for 30 minutes, turn on the cooling water and start vacuuming to evaporate the ethanol solvent. When the temperature of the mixed solution in the reactor reaches 70 ℃, and when no liquid distills out, stop vacuuming and heating;

[0024] (3) Use a funnel to filter out the crystals in the feed liquid to obtain a light yellow liquid product.

Embodiment 3

[0026] A kind of synthetic method of dibutyltin dilaurate, comprising the following steps: (1) add 200g lauric acid, 123.3g dichloro Dibutyltin and 100mL of absolute ethanol, inject 226.6g of sodium ethoxide-ethanol solution with a mass fraction of 32% into the constant pressure dropping funnel, start heating and stirring, when the temperature of the mixed solution reaches 55°C, add the sodium ethoxide-ethanol solution dropwise , keep the dropping rate at 5mL / min;

[0027] (2) After the sodium ethoxide-ethanol solution is added dropwise, keep the temperature at 50-60°C. After reacting for 30 minutes, turn on the cooling water and start vacuuming to evaporate the ethanol solvent. When the temperature of the mixed solution in the reactor reaches 70 ℃, and when no liquid distills out, stop vacuuming and heating;

[0028] (3) Use a funnel to filter out the crystals in the feed liquid to obtain a light yellow liquid product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com