Preparation process of dibutyltin oxide

A technology of dibutyltin oxide and dibutyltin chloride, which is applied in the fields of organic chemistry, tin organic compounds, chemical instruments and methods, etc., can solve problems such as complicated process, poor effect, and increased production cost, and achieve the goal of preparing The reaction process is simple, easy to wash and dry, and the effect of saving raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

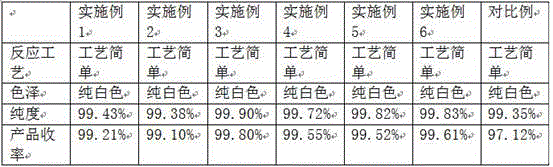

Embodiment 1

[0028] 607.4g dibutyl tin chloride and 1.2g n-heptane are added in the reactor that thermometer and stirrer are housed, be warmed up to 60 ℃, then dropwise add 1600g mass concentration with the dropping rate of 14Kg / min in the reactor. 10% sodium hydroxide solution, about 2.5 hours to drop, after the drop, continue to stir and react at constant temperature for 1 hour;

[0029] The reaction solution after the stirring reaction was left to stand for stratification for 1.5 hours, and the supernatant was separated, and transferred to the secondary reactor, and then 80 g of 10% mass concentration was added dropwise to the secondary reactor at a rate of 14Kg / min. Sodium hydroxide solution, controlled reaction temperature 50 DEG C to react for 3 hours, after the reaction finished, the reaction solution in the secondary reactor was allowed to stand for stratification for 2 hours;

[0030] Transfer the upper layer solution in the secondary reactor to the distiller, distill out n-heptan...

Embodiment 2

[0032] 607.4g dibutyl tin chloride and 1.2g n-heptane are added in the reactor that thermometer and stirrer are housed, be warmed up to 60 ℃, dropwise with the dropping rate of 14Kg / min in the reactor then 1640g mass concentration is 10% sodium hydroxide solution, about 2.5 hours to drop, after the drop, continue to stir and react at constant temperature for 1 hour;

[0033] The reaction solution after the stirring reaction was left to stand for stratification for 1 hour, and the supernatant was separated, and transferred to the secondary reactor, and then 160 g of 10% mass concentration was added dropwise to the secondary reactor at a rate of 14Kg / min. Sodium hydroxide solution, controlled reaction temperature 50 DEG C to react for 3 hours, after the reaction finished, the reaction solution in the secondary reactor was allowed to stand for stratification for 2 hours;

[0034] Transfer the upper layer solution in the secondary reactor to the distiller, distill out n-heptane at...

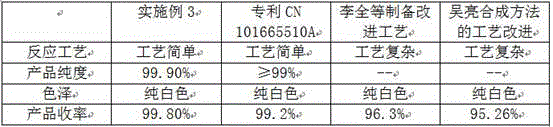

Embodiment 3

[0036] Add 607.4g of dibutyltin chloride and 1g of n-heptane into a reactor equipped with a thermometer and a stirring device, raise the temperature to 60°C, and then dropwise add 1680g of 1680g with a mass concentration of 10 to the reactor at a rate of 14Kg / min. % sodium hydroxide solution, drop it in about 2.5 hours, after the drop, continue to stir and react at a constant temperature for 1 hour;

[0037] The reaction solution after the stirring reaction was left to stand for stratification for 2 hours, and the supernatant was separated, and transferred to the secondary reactor, and then 80 g of 10% mass concentration was added dropwise to the secondary reactor at a rate of 14Kg / min. Sodium hydroxide solution, controlled reaction temperature 50 DEG C to react for 3 hours, after the reaction finished, the reaction solution in the secondary reactor was allowed to stand for stratification for 2 hours;

[0038] Transfer the upper layer solution in the secondary reactor to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com