Mixing method for preparing geopolymer cement soil

A geopolymer and cement-soil technology, applied in cement production and other directions, can solve problems such as affecting the performance of cement-soil, unable to ensure uniform mixing of cement, geopolymer and soft soil, etc., so as to reduce engineering construction costs and solve the phenomenon of agglomeration. , the effect of improving strength and failure strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Raw material preparation

[0024] 500g of dry soil, spray wet with optimal moisture content, soak for a day and night.

[0025] Flake NaOH 3.15g, dissolve NaOH solid in water to make a solution with a concentration of 50%.

[0026] Water glass solution 18.15g, the water glass solution after weighing is poured into NaOH solution, is configured as alkali activator.

[0027] 60g of cement is 42.5 grade ordinary Portland cement.

[0028] Metakaolin 15g.

[0029] The mixing ratio chosen for this test is 3% of metakaolin and 12% of cement. Made into a cube specimen of 70.7×70.7×70.7mm

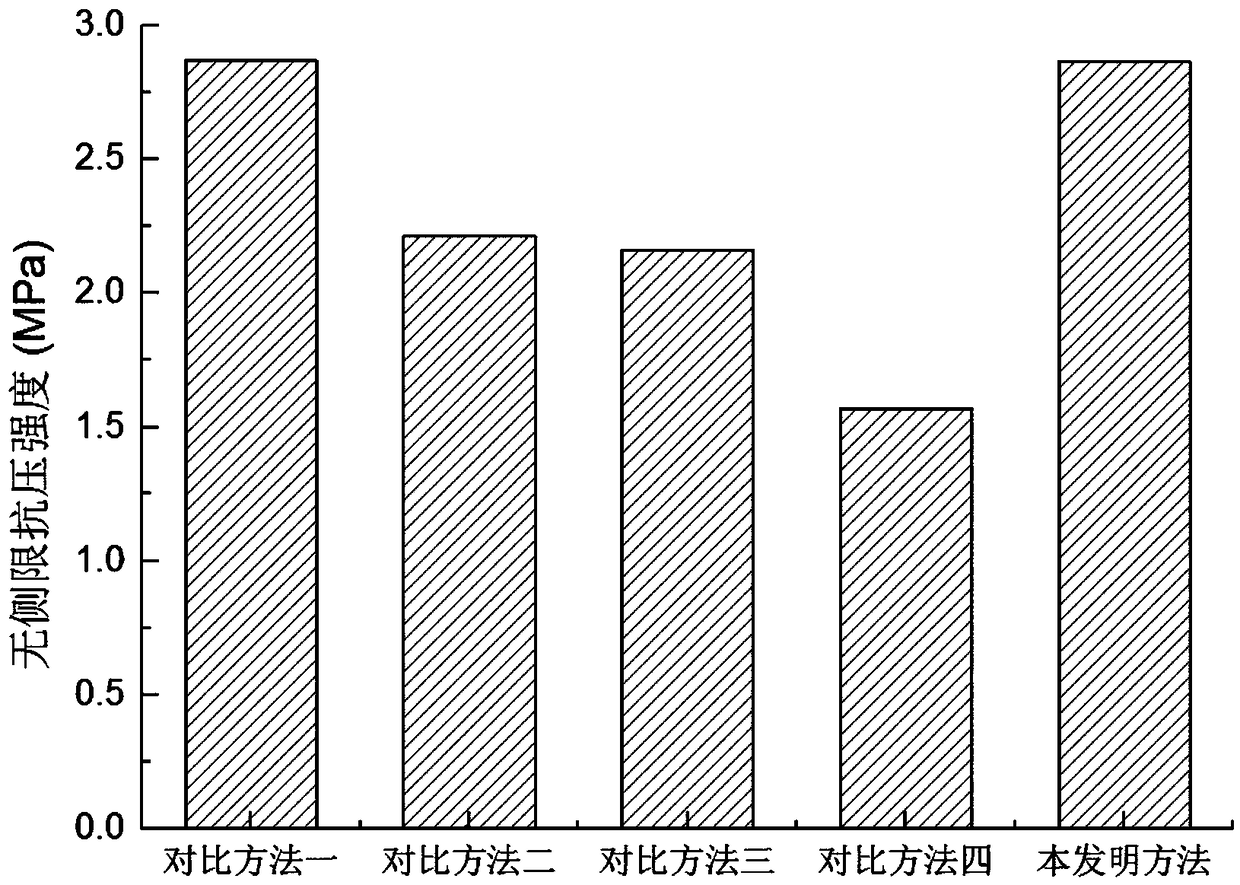

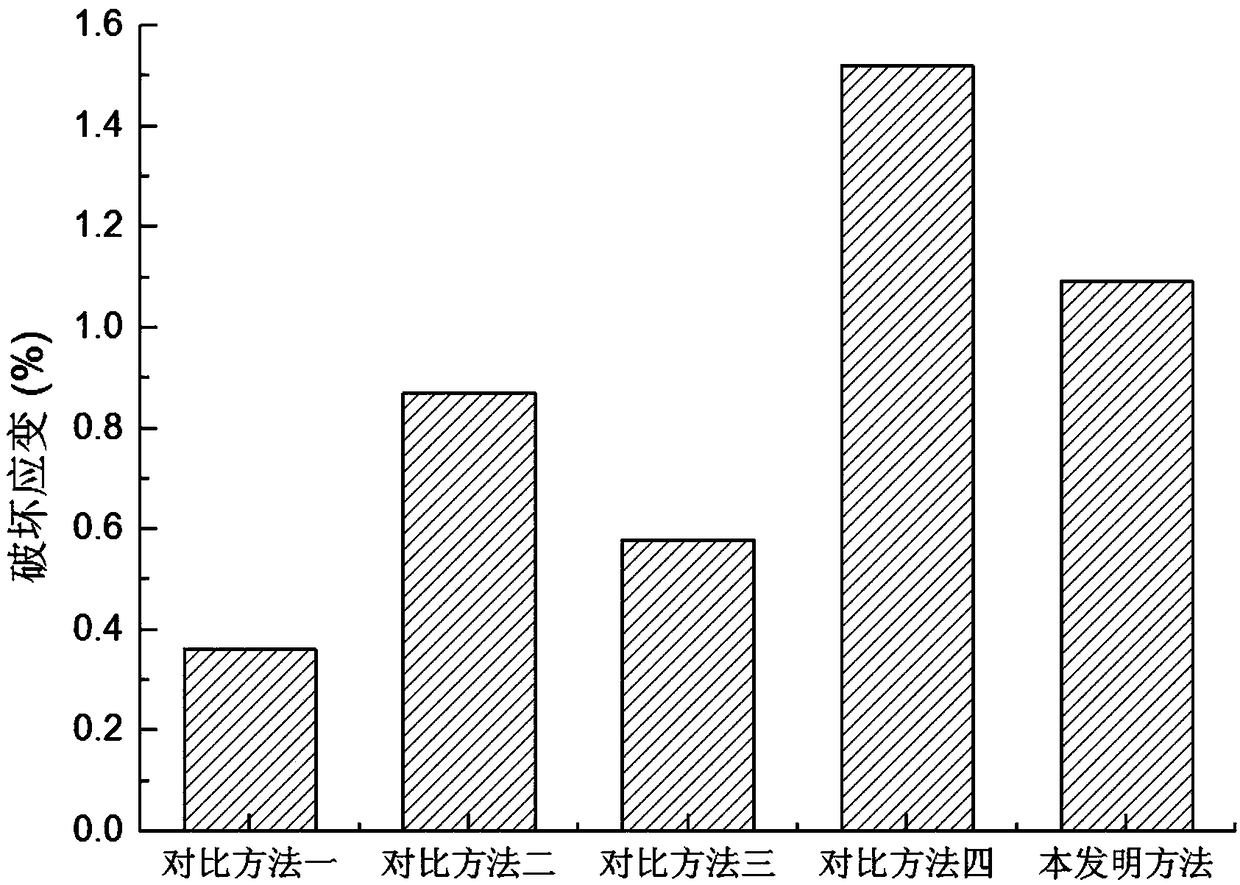

[0030] The first comparison method is dry soil mixing, and the geopolymer is prepared first, and then the geopolymer is poured into the dry soil.

[0031] The second comparison method is wet soil mixing, and the geopolymer is prepared first, and the geopolymer is poured into the wet soil.

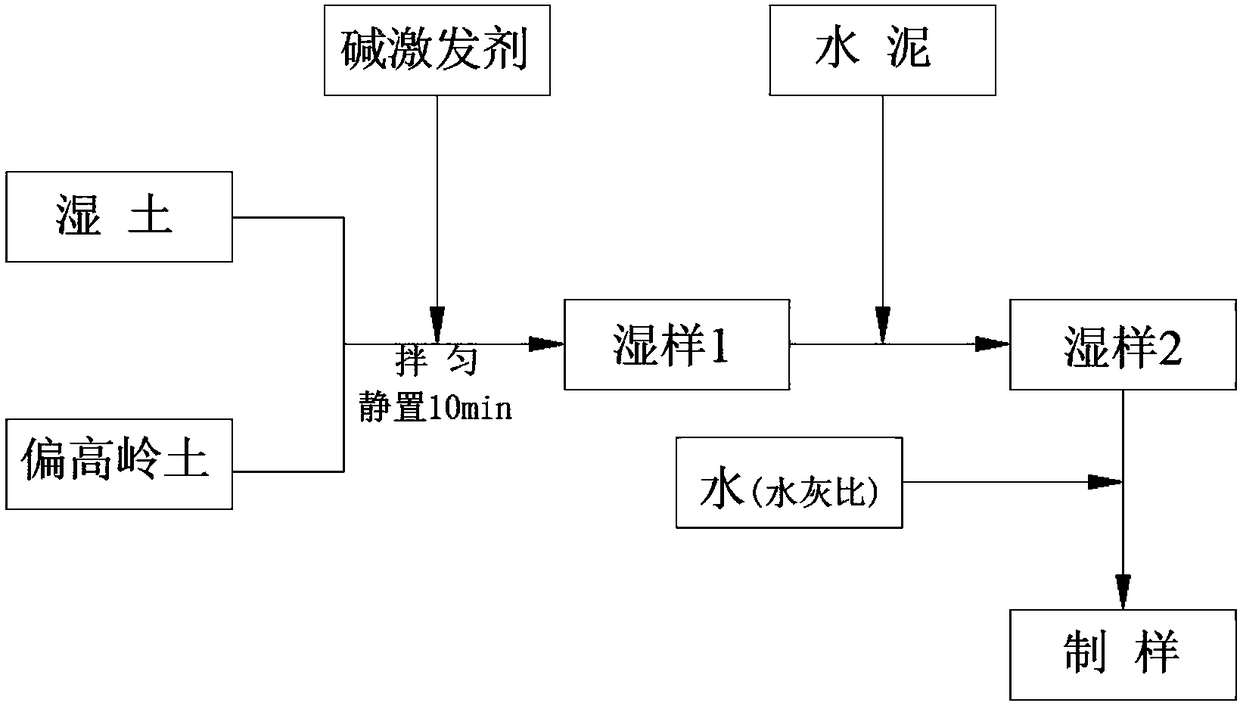

[0032] The following table shows the mixing method of geopolymer cement soil

[0033]

[0034]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com