Preparation method of high-purity dibutyltin oxide

A technology of dibutyltin oxide and dibutyltin chloride, which is applied in chemical instruments and methods, organic chemistry, tin organic compounds, etc., can solve the problems of aggravating water pollution and consuming water resources, so as to reduce water pollution, The effect of saving water resources and reducing the content of chloride ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

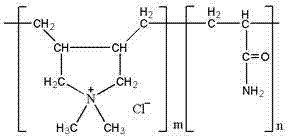

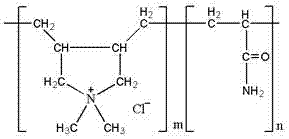

[0021] 607.4kg of dibutyltin chloride is dissolved in 500kg of toluene, and is dropped into the solution containing 1600kg of 10% sodium hydroxide and 0.4kg of surfactant at a rate of 14kg / min, wherein the molecules of surfactant In the structural formula, m takes a value of 10, and n takes a value of 2. The temperature was controlled at 50°C, and the stirring reaction was continued for 2 hours after the dripping was completed;

[0022] The reaction solution after the stirring reaction was allowed to stand for 1.5 hours to separate layers, and the upper organic solvent layer was separated and collected for later use. Add 400kg of deionized water into the distiller, heat to 90°C, then add dropwise an organic solvent containing dibutyltin oxide, and distill to recover the toluene solvent. The remaining water phase after distillation was centrifuged and dried to prepare 495.2 kg of white dibutyltin oxide powder.

[0023] The productive rate of the present embodiment is 99.54%. ...

Embodiment 2

[0025] Dissolve 607.4kg of dibutyltin chloride in 800kg of toluene, drop in 2240kg of potassium hydroxide with a mass concentration of 10% at a rate of 14kg / min, control the temperature at 45°C, and continue to stir for 2.5 hours after the drop;

[0026] The reaction solution after the stirring reaction was left to stand for 2 hours and separated into layers, and the upper organic solvent layer was separated and collected for later use. Add 400kg of deionized water into the distiller, heat to 95°C, then add dropwise an organic solvent containing dibutyltin oxide, and distill to recover the toluene solvent. The remaining water phase after distillation was centrifuged and dried to prepare 493.4 kg of white dibutyltin oxide powder.

[0027] The productive rate of the present embodiment is 99.18%.

Embodiment 3

[0029] Dissolve 607.4kg of dibutyltin chloride in 650kg of cyclohexane, drop 1680kg of sodium hydroxide with a mass concentration of 10% at a rate of 15kg / min, control the temperature at 50°C, and continue to stir the reaction after dripping 3 Hour;

[0030] The reaction solution after the stirring reaction was left to stand for 2 hours and separated into layers, and the upper organic solvent layer was separated and collected for later use. Add 350 kg of deionized water into the distiller, heat to 95° C., then dropwise add an organic solvent containing dibutyltin oxide, and recover the cyclohexane solvent by distillation. The remaining water phase after distillation was centrifuged and dried to prepare 495.9 kg of white dibutyltin oxide powder.

[0031] The productive rate of the present embodiment is 99.48%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com