Treatment method of dibutyltin oxide and application of treatment method to synthesis of cane sugar-6-ethyl ester

A dibutyltin oxide and treatment method technology, applied in the direction of chemical instruments and methods, esterified saccharides, tin organic compounds, etc., can solve problems such as dust interference, difficulty in vacuum dehydration, and existing safety, so as to avoid hazards and Potential safety hazards, suitable for industrial production, not easy to damage and lose effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

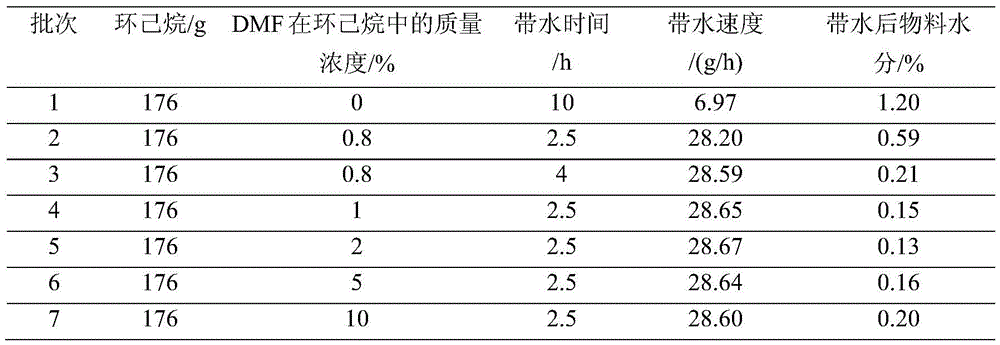

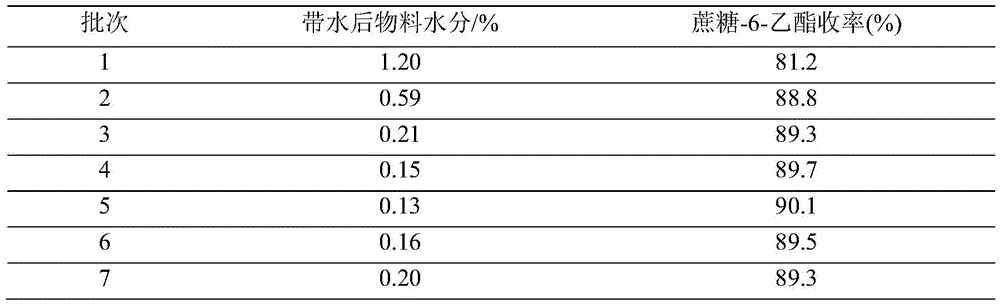

[0033] (1) Weigh 90g of sucrose, 72g of dibutyltin oxide into a 1000ml three-neck flask, add 550ml of N,N-dimethylformamide, 225ml of cyclohexane, heat up to reflux, keep warm at 83-85°C and reflux to separate water 3h. The temperature was lowered to 10°C and 29.63 g of acetic anhydride was added dropwise, and the reaction was stirred for 1.5 h.

[0034] (2) 50ml of water was added, and 300ml of cyclohexane was added to extract the organotin in the reaction solution. Separation, the upper layer is a cyclohexane solution containing DSDA, and the lower layer is extracted with 300ml*2 cyclohexane to extract the remaining organotin. Concentrate the lower layer at no more than 80°C to remove water, cyclohexane and most of DMF. After detection by high performance liquid chromatography, 1.2% of sucrose remains, and the yield of sucrose-6-ethyl ester is 89.7%.

[0035](3) Combine the cyclohexane extracts, concentrate under reduced pressure until the concentrate is 260 to 350 g, and ...

Embodiment 2

[0038] In step (4) of Example 1, dibutyltin oxide containing water was azeotropically dried with DMF-free cyclohexane with water. Repeat Example 1 to obtain hydrated dibutyltin oxide. The specific operation is as follows: add 225ml of cyclohexane, heat up to reflux, keep warm and reflux to separate water for 4 hours, and the obtained dibutyltin oxide cyclohexane liquid has a water content of about 2.28% (w / w) as determined by the Karl Fischer method.

Embodiment 3

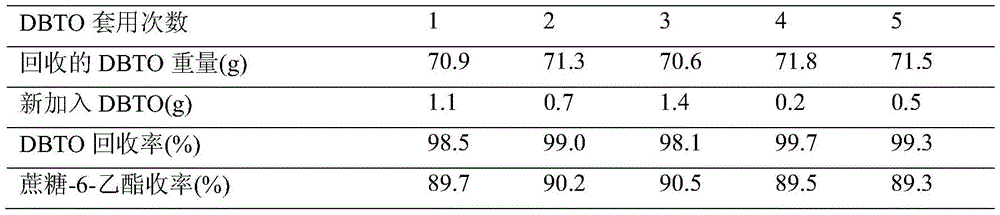

[0040] The dibutyltin oxide cyclohexane solution obtained in Example 1 was used to prepare sucrose-6-ethyl ester, and the operating conditions were repeated in Example 1. The dibutyltin oxide cyclohexane solution obtained in this experiment was again prepared under the same conditions to prepare sucrose-6-ethyl ester. The relevant dibutyl tin oxide recovery that the experiment of dibutyl tin oxide recycling obtains like this, the yield of sucrose-6-ethyl ester and the data such as number of times of applying mechanically are summarized in the following table. The weight of dibutyltin oxide is obtained by subtracting the weight of cyclohexane from the weight of dibutyltin oxide cyclohexane.

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com