Corrosion resistant unsaturated polyester resin and preparation method thereof

A polyester resin and corrosion-resistant technology, which is applied in the field of corrosion-resistant unsaturated polyester resin and its preparation, can solve problems such as insufficient corrosion resistance of unsaturated polyester resin, and achieve the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

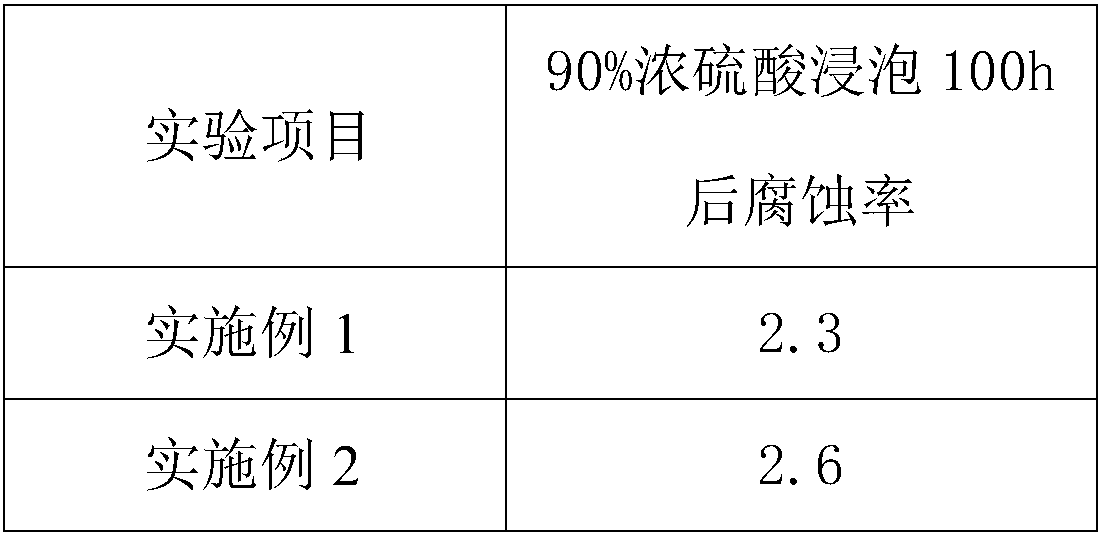

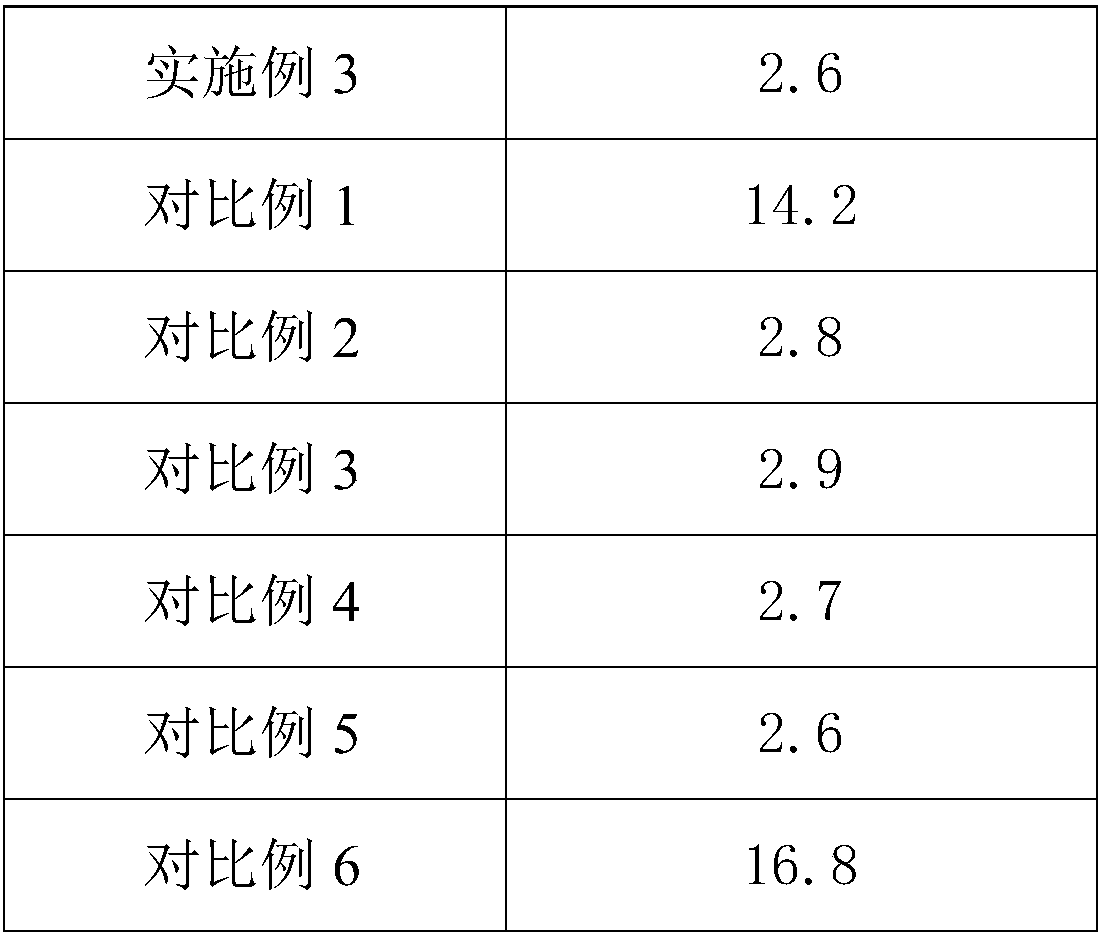

Examples

preparation example Construction

[0021] The preparation method of described corrosion-resistant unsaturated polyester resin, comprises the following steps:

[0022] S1. Mix unsaturated polyester resin, silicone resin, trimethyl phosphate, alkyd resin, dicyclopentadiene, dibutyl ethyl tin oxide, isophthalic anhydride, and triisocyanuric acid ester evenly, Raise the temperature to 70-80°C, keep it warm for 20-30min, then add polycarbonate, cobalt isooctanoate, cobalt cyclopentanoate, hexafluorobutyl methacrylate, methyl ethyl ketone peroxide, oleic acid, dibutyl ethyl tin oxide, formazan Mix hexafluorobutyl acrylate, trimethylolpropane diallyl ether, castor oil, precipitated barium sulfate, and glass flakes evenly, continue to heat up to 70-80°C, keep warm for 30-50min, and then heat at 350-450r / min Stir at a rotating speed for 10-20min, cool to room temperature to obtain the base material;

[0023] S2. Mix cellulose acetate, zinc acetate, silane coupling agent KH-560, and corrosion-resistant modification addi...

Embodiment 1

[0027] A corrosion-resistant unsaturated polyester resin, in parts by weight, comprising the following raw materials: 100 parts of unsaturated polyester resin, 6 parts of silicone resin, 6 parts of trimethyl phosphate, 4 parts of alkyd resin, dicyclopentadiene 6 parts of alkene, 6 parts of dibutyl ethyl tin oxide, 4 parts of isophthalic anhydride, 3 parts of triisocyanuric acid ester, 4.5 parts of polycarbonate, 3 parts of cobalt isooctanoate, 6 parts of cobalt cyclopentanoate, 4.5 parts of hexafluorobutyl methacrylate, 3 parts of methyl ethyl ketone peroxide, 4.5 parts of oleic acid, 6 parts of dibutyl ethyl tin oxide, 6 parts of hexafluorobutyl methacrylate, trimethylolpropane diallyl ether 3.5 parts, castor oil 3 parts, precipitated barium sulfate 6 parts, glass flakes 4 parts, cellulose acetate 11 parts, zinc acetate 7.5 parts, silane coupling agent KH-560 3 parts, corrosion resistance modification additive 22 parts.

[0028] The corrosion-resistant modification additive i...

Embodiment 2

[0034] A corrosion-resistant unsaturated polyester resin, in parts by weight, comprising the following raw materials: 80 parts of unsaturated polyester resin, 8 parts of silicone resin, 3 parts of trimethyl phosphate, 6 parts of alkyd resin, dicyclopentadiene 4 parts of alkene, 9 parts of dibutyl ethyl tin oxide, 2 parts of isophthalic anhydride, 5 parts of triisocyanuric acid ester, 3 parts of polycarbonate, 5 parts of cobalt isooctanoate, 4 parts of cobalt cyclopentanoate, 6 parts of hexafluorobutyl methacrylate, 1 part of methyl ethyl ketone peroxide, 6 parts of oleic acid, 4 parts of dibutyl ethyl tin oxide, 9 parts of hexafluorobutyl methacrylate, trimethylolpropane diallyl ether 2 parts, 5 parts of castor oil, 4 parts of precipitated barium sulfate, 6 parts of glass flakes, 8 parts of cellulose acetate, 9 parts of zinc acetate, 2 parts of silane coupling agent KH-560, 26 parts of corrosion resistance modification additive.

[0035] The corrosion-resistant modification ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com