Waterborne polyester resin and preparation method as well as functional auxiliary agent based on waterborne polyester resin

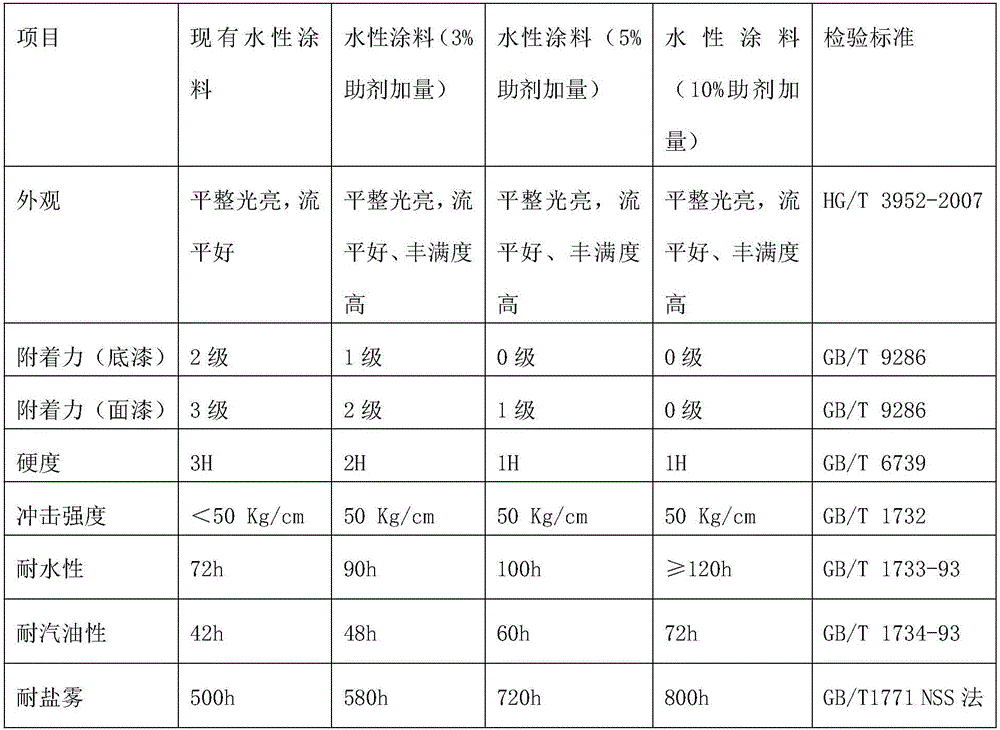

A technology of water-based polyester resin and trimethylolpropane, applied in the field of water-based polyester resin, can solve the problems of high gloss, unsatisfactory weather resistance, insufficient adhesion of water-based paint coating, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] On the other hand, the present invention provides a kind of preparation method of waterborne polyester resin, comprises the following steps;

[0022] Add 25-30g neopentyl glycol, 15-18g trimethylolpropane, 18-22g sodium isophthalic acid-5-sulfonate, 25-30g adipic acid and 0.05-0.08g dibutyltin oxide into the belt In the reaction vessel of the stirrer and the condenser, pass nitrogen gas, slowly raise the temperature to 130°C to melt the material completely, then raise the temperature to 170°C, keep it warm for 1 hour, then raise the temperature to 210°C at a heating rate of 10°C / h, and keep it Temperature esterification until the acid value (KOH) reaches 5-8 mg / g;

[0023] Then cool down to 180°C, add 5-8g of hexahydrophthalic acid, heat up to 200°C for constant temperature esterification for 2 hours, wait until the acid value (KOH) reaches 30-35 mg / g, and the hydroxyl value (KOH) reaches 60-70 mg / g Finally, lower the temperature to below 100°C and add 12-15g ethylene ...

Embodiment 1

[0026] The invention provides a water-based polyester resin, which is composed of the following raw materials: 15g of trimethylolpropane, 25g of neopentyl glycol, 18g of isophthalic acid-5-sodium sulfonate, 25g of adipic acid, and phthalic acid 5g, ethylene glycol butyl ether 12g, sec-butanol 8g, dibutyltin oxide 0.05g, dimethylethanolamine 8g.

[0027] The invention provides a kind of preparation method of waterborne polyester resin, comprises the following steps;

[0028] Add 25g of neopentyl glycol, 15g of trimethylolpropane, 18g of isophthalic acid-5-sodium sulfonate, 25g of adipic acid and 0.05g of dibutyltin oxide into a reaction vessel with a stirrer and a condenser tube, Through nitrogen, slowly raise the temperature to 130°C to melt the material completely, then raise the temperature to 170°C, keep it warm for 1 hour, then raise the temperature to 210°C at a heating rate of 10°C / h, and keep this temperature for esterification until the acid value (KOH) up to 5mg / g; ...

Embodiment 2

[0031] The invention provides a water-based polyester resin, which is composed of the following raw materials: 18g of trimethylolpropane, 30g of neopentyl glycol, 22g of isophthalic acid-5-sodium sulfonate, 30g of adipic acid, and phthalic acid 8g, ethylene glycol butyl ether 15g, sec-butanol 10g, dibutyltin oxide 0.08g, dimethylethanolamine 10g.

[0032] The invention provides a kind of preparation method of waterborne polyester resin, comprises the following steps;

[0033] 30g of neopentyl glycol, 18g of trimethylolpropane, 22g of isophthalic acid-5-sodium sulfonate, 30g of adipic acid and 0.08g of dibutyltin oxide are added to a reaction vessel with a stirrer and a condenser tube, Through nitrogen, slowly raise the temperature to 130°C to melt the material completely, then raise the temperature to 170°C, keep it warm for 1 hour, then raise the temperature to 210°C at a heating rate of 10°C / h, and keep this temperature for esterification until the acid value (KOH) up to 8m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com