A kind of preparation method of high-performance nickel-based alloy composite strip

A technology of composite strips and nickel-based alloys, applied in metal rolling, manufacturing tools, temperature control, etc., can solve problems such as difficult to achieve strong cubic texture, and achieve the effect of good interlayer interface bonding force and uniform surface structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

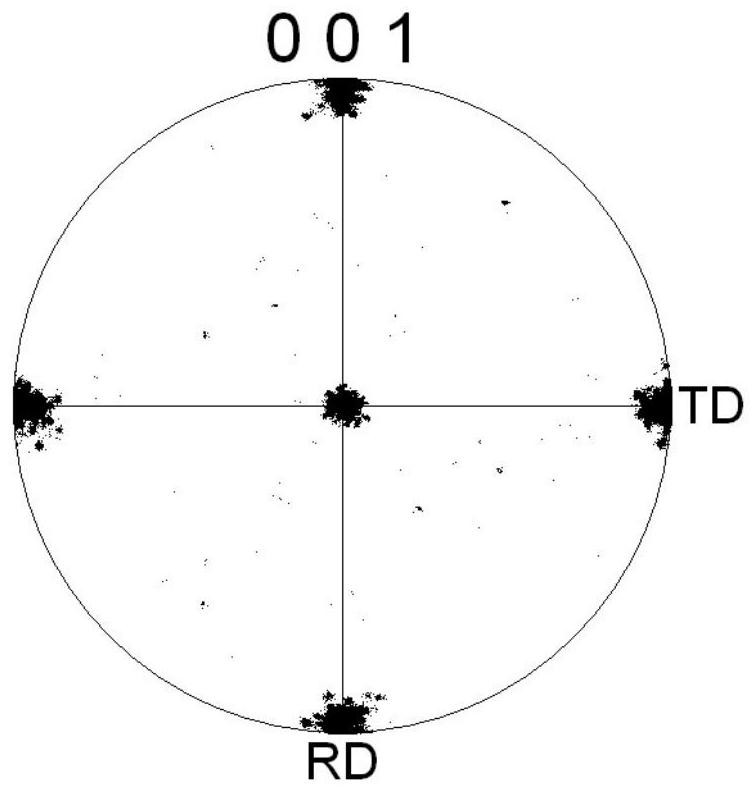

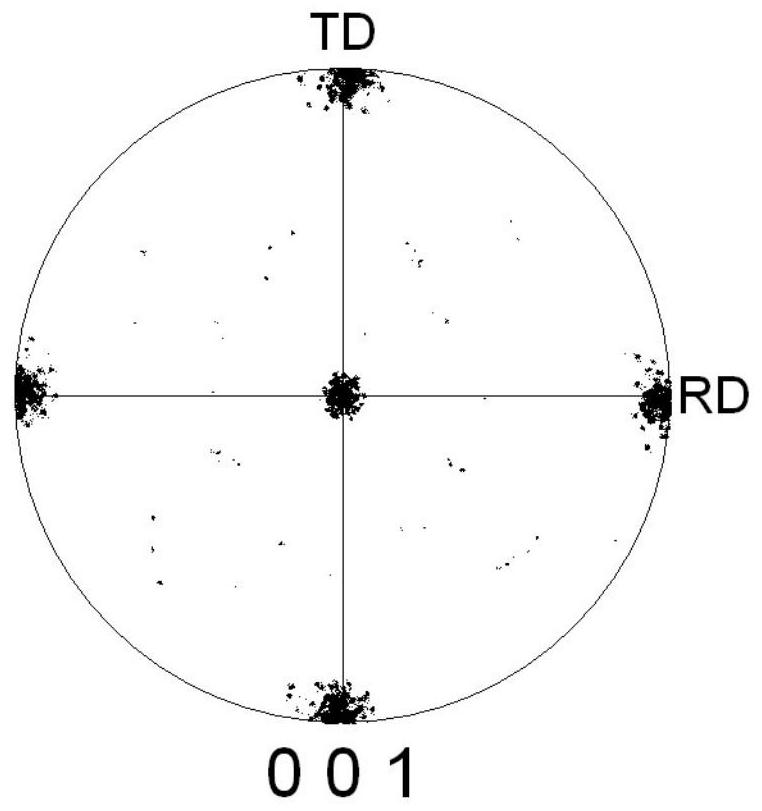

Image

Examples

Embodiment 1

[0033] The steps of the preparation method of the embodiment of the present invention 1 are as follows:

[0034] Firstly, the Ni-9at.%W and Ni-12at.%W alloy ingots were obtained by vacuum induction melting, and the two ingots were directly hot-rolled to a thickness of 15mm, and the hot-rolling temperature was 1280°C, and then Ni-9at. The .%W hot-rolled sheet is the surface layer material, as the upper and lower layers, and the Ni-12at.%W hot-rolled sheet is the core layer material, and the continuous extrusion method is used to obtain 12mm thick Ni-9at.%W / Ni-12at.% W / Ni-9at.% W composite strip with three-layer structure;

[0035] Perform cold rolling deformation on the composite billet to obtain an alloy base strip with a thickness of 80 μm, and the thickness reduction of each pass is controlled at 5% to 20%;

[0036] Add low-temperature annealing to the above cold rolling process. The specific process is to keep warm at 480°C for 30 minutes when cold rolling to 5mm thick, an...

Embodiment 2

[0040] The steps of the preparation method of the embodiment of the present invention 2 are as follows:

[0041] Firstly, the Ni-9at.%W and Ni-12at.%W alloy ingots were obtained by vacuum induction melting, and the two ingots were directly hot-rolled to a thickness of 15mm, and the hot-rolling temperature was 1280°C, and then Ni-9at. The .%W hot-rolled sheet is the surface layer material, as the upper and lower layers, and the Ni-12at.%W hot-rolled sheet is the core layer material, and the 10mm thick Ni-9at.%W / Ni-12at.% is obtained by continuous extrusion W / Ni-9at.% W composite strip with three-layer structure;

[0042] Perform cold rolling deformation on the composite billet to obtain an alloy base strip with a thickness of 80 μm, and the thickness reduction of each pass is controlled at 5% to 20%;

[0043] Add low-temperature annealing to the above cold rolling process. The specific process is to keep warm at 480°C for 40 minutes when cold rolling to 5mm thick, and then kee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com