A kind of pvdc emulsion and its solar cell backboard

A technology of solar cells and emulsions, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of difficulty in ensuring the adhesion fastness of the support layer, affecting the quality of film formation, and difficult volatilization of solvents, etc., so as to reduce the water vapor transmission rate and interface Improvement of bonding fastness and improvement of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

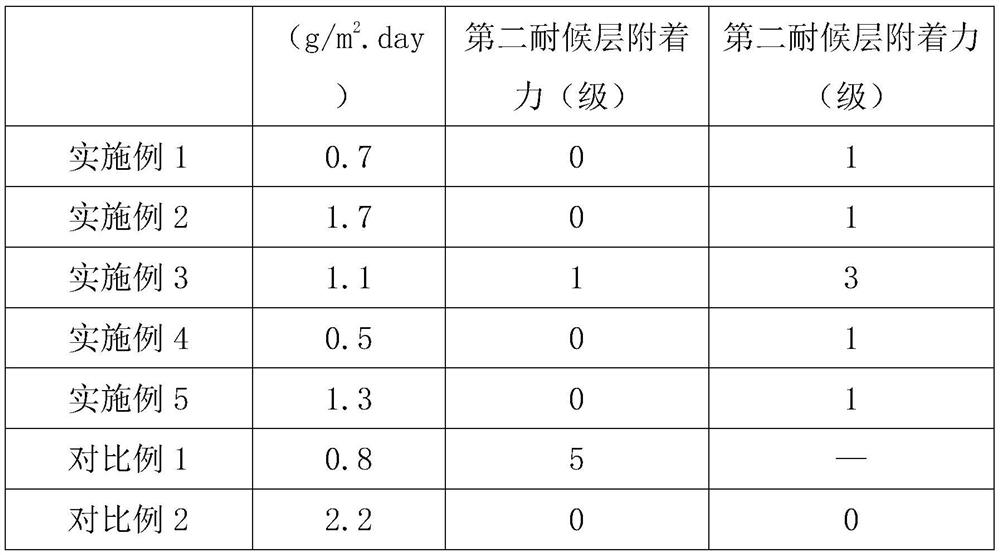

Embodiment 1

[0037] Preparation of modified PVDC emulsion 1: Weigh 100g of vinylidene chloride monomer, 28.6g of glycidyl methacrylate monomer, 4g of sodium dodecylsulfonate, 0.4g of initiator ammonium persulfate, and 70g of deionized water , adjust the pH of the emulsion to 6, in the pass N 2 Under the conditions, the temperature was raised to 50° C., stirred for 10 h, cooled and discharged, and modified PVDC emulsion 1 was obtained.

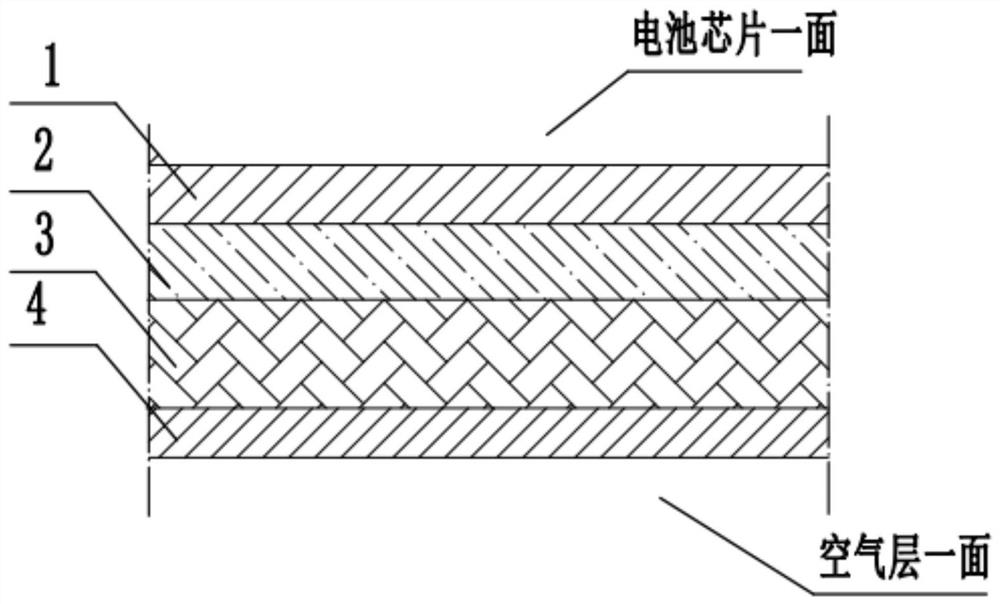

[0038] The substrate layer uses semi-permeable PET with a thickness of 250 μm.

[0039] Production of the backsheet: Coat one side of the PET with 65% modified PVDC emulsion 1, and dry at 90°C for 2 minutes; obtain a barrier layer with a thickness of 6 μm; coat a second weather-resistant layer with a dry thickness of 3 μm on the barrier layer. The other side of the PET was coated with the first weather-resistant layer with a dry thickness of 20 μm, and the performance of the sample was tested after aging at 50°C for 3 days.

Embodiment 2

[0041] Preparation of modified PVDC emulsion 2: Weigh 46 g of vinylidene chloride monomer, 13 g of glycidyl acrylate monomer, 2 g of sodium lauryl sulfate, 0.4 g of initiator potassium persulfate, and 140 g of deionized water to adjust the pH of the emulsion for 6, in thru N 2 Under the conditions, the temperature was raised to 50° C., stirred for 10 h, cooled and discharged, and modified PVDC emulsion 2 was obtained.

[0042] The substrate layer uses semi-permeable PET with a thickness of 220 μm.

[0043] Production of the backsheet: Coat one side of the PET with 30% modified PVDC emulsion 2, and dry at 90°C for 2 minutes; obtain a barrier layer with a thickness of 1 μm; coat a second weather-resistant layer with a dry thickness of 10 μm on the barrier layer. The other side of the PET was coated with the first weather-resistant layer with a dry thickness of 16 μm, and the performance of the sample was tested after aging at 50°C for 3 days.

Embodiment 3

[0045] Preparation of modified PVDC emulsion 3: Weigh 79g of vinylidene chloride monomer, 31g of allyl glycidyl ether monomer, 2g of sodium lauryl sulfate, 0.6g of initiator potassium persulfate, 90g of deionized water, adjust The pH of the emulsion is 6, in the pass N 2 Under the conditions, the temperature was raised to 50° C., stirred for 10 h, cooled and discharged, and modified PVDC emulsion 3 was obtained.

[0046] The substrate layer uses semi-permeable PET with a thickness of 180 μm.

[0047] The production method of the back sheet: apply 55% modified PVDC emulsion 3 on one side of the PET, and dry at 90°C for 2 minutes; obtain a barrier layer with a thickness of 20 μm; coat a second weather-resistant layer with a dry thickness of 20 μm on the barrier layer, The first weather-resistant layer with a dry thickness of 30 μm was coated on the other side of the PET, and the performance of the sample was tested after aging at 50°C for 3 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com