Patents

Literature

108 results about "Vinylidene Chlorides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water and oil repellent composition and treatment method

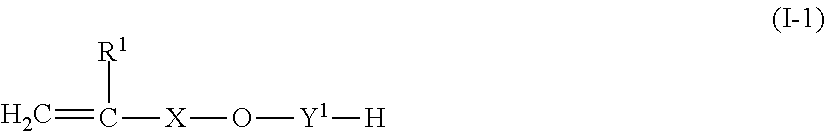

InactiveUS20070088141A1Improve performanceImprove copolymerization performanceFibre treatmentEmulsion paintsCarbon atomStereochemistry

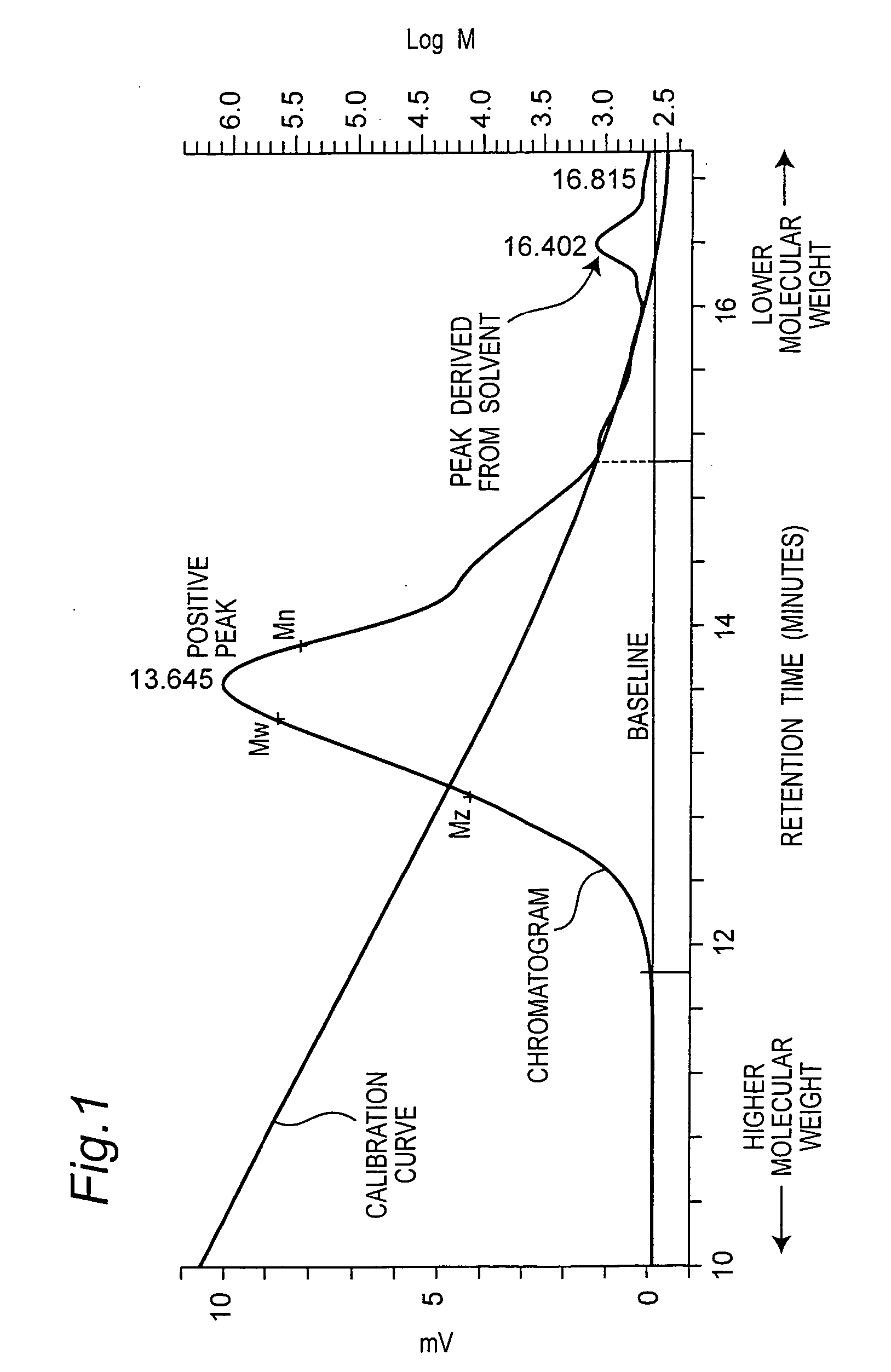

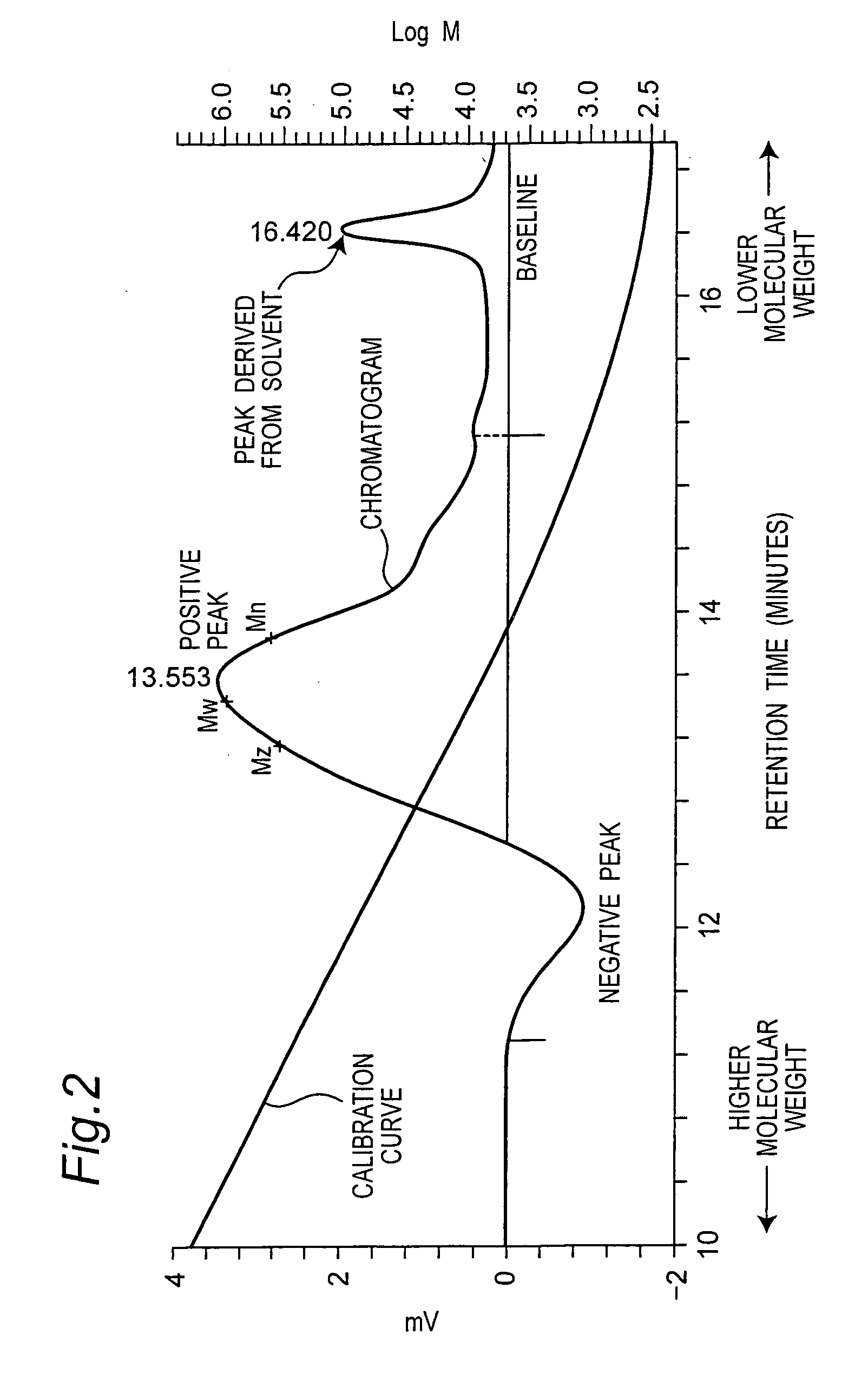

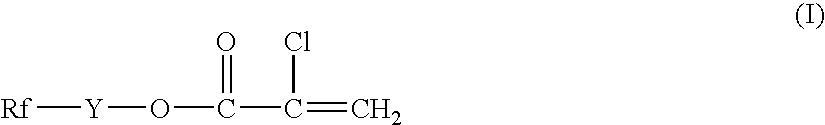

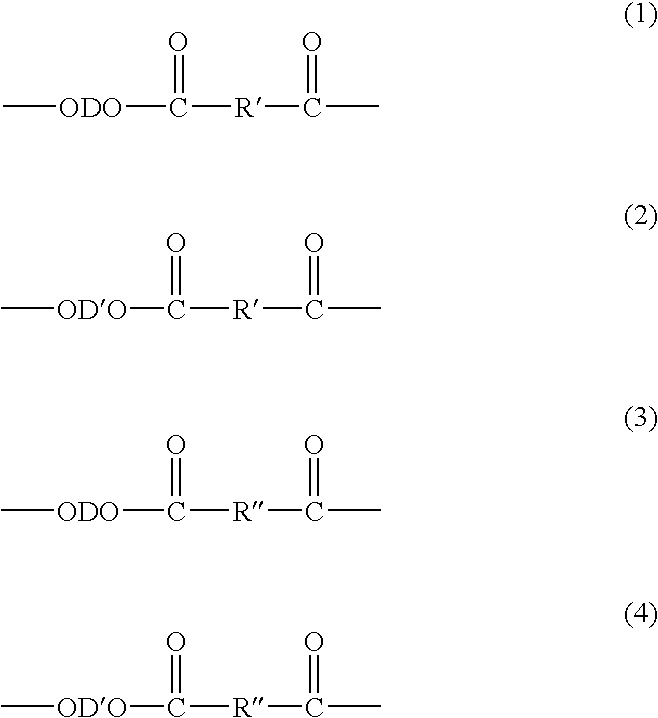

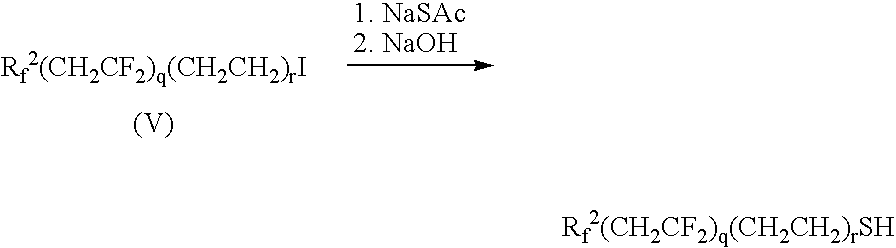

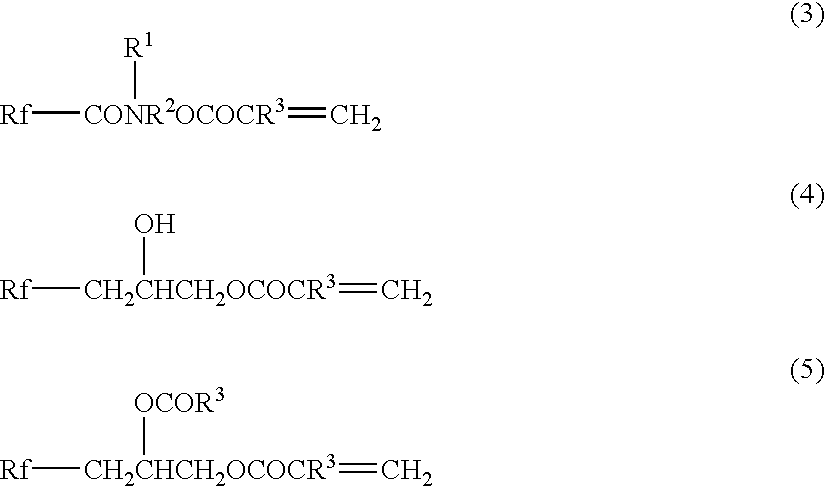

Disclosed is a water- and oil-repellent agent comprising the following fluorine-containing copolymer (A). The fluorine-containing copolymer (A) comprises: (a1) a fluoroalkyl group-containing polymerizable monomer of the formula: wherein Y is a divalent organic group [for example, an aliphatic group having 1 to 10 carbon atoms, an aromatic or cycloaliphatic group having 6 to 10 carbon atoms, a —SO2N(R1)R2— group (in which R1 is a hydrogen atom or an alkyl group having 1 to 4 carbon atoms, and R2 is an alkylene group having 1 to 10 carbon atoms), a —CON(R1)R2— group (in which R1 is a hydrogen atom or an alkyl group having 1 to 4 carbon atoms, and R2 is an alkylene group having 1 to 10 carbon atoms), or a —CH2CH(OY1)CH2— group (in which Y1 is a hydrogen atom or an acyl group having 1 to 4 carbon atoms)]; and Rf is a linear or branched fluoroalkyl or fluoroalkenyl group having 1 to 6 carbon atoms; and (a2) vinylidene chloride.

Owner:DAIKIN IND LTD

Water PVDC latex specially for painting special cloth and its preparing method

InactiveCN1986583AReduce contentImprove water resistanceTextiles and paperPolymer scienceNonwoven fabric

The present invention relates to water-thinned PVDC latex, and is especially a kind of water-thinned PVDC latex for painting special cloth and its preparation process. The water-thinned PVDC latex is prepared with mixed monomer through emulsion polymerization in the presence of emulsifier and initiator. The mixed monomer includes vinylidene chloride 75-90 %, acrylate monomer 8-20 % and unsaturated fatty acid 1-5 %. The water-thinned PVDC latex is used in treating non-woven fabric, and the treated non-woven fabric is hard, elastic, waterproof, heat resistant and crease resistant and may be used widely. In addition, the water-thinned PVDC latex has excellent compatibility with acrylic acid emulsion.

Owner:ZHEJIANG SENLANDE PACKAGING TECH

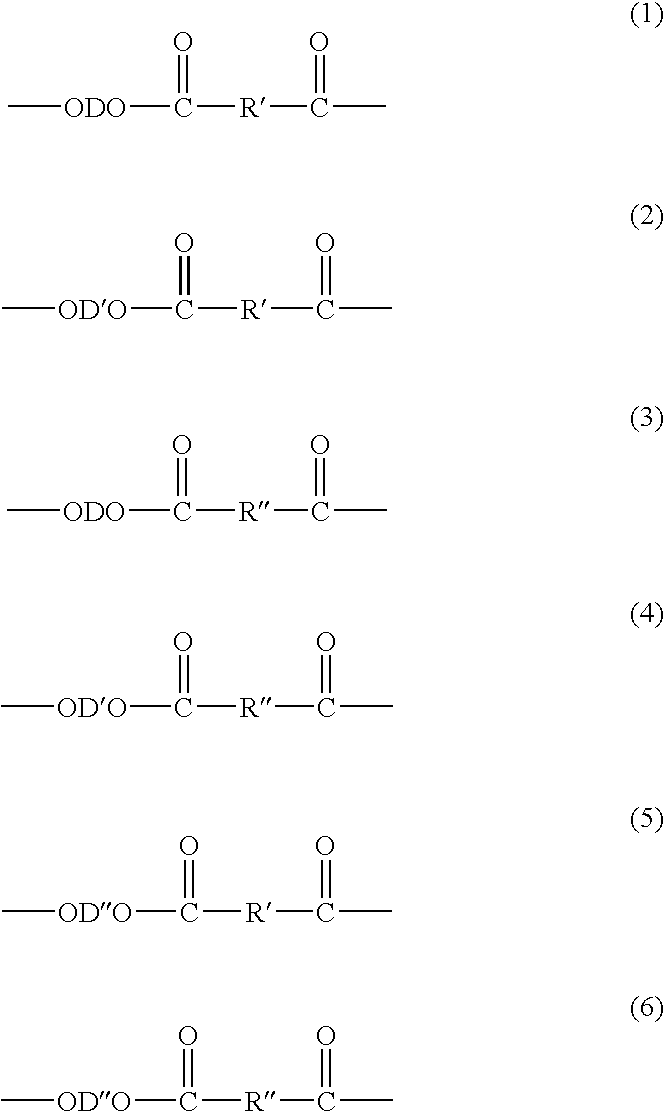

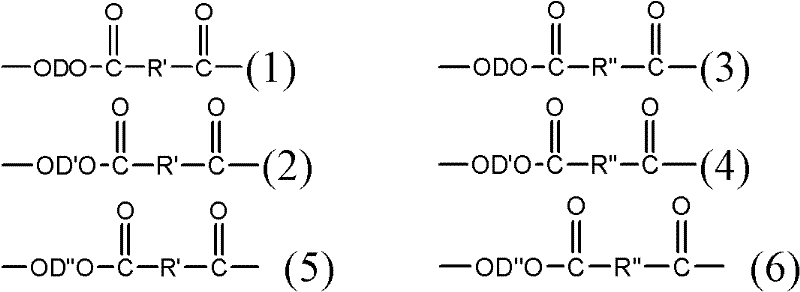

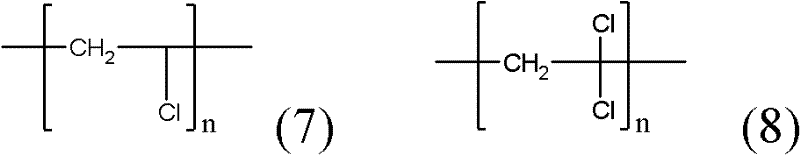

Poly(butylene terephthalate) compositions, methods of manufacture, and articles thereof

InactiveUS20100168317A1Improved flow and mechanical propertyImprove protectionPolyethylene terephthalatePolyamide

A composition comprises, from 5 to 90 wt. % of a modified poly(butylene terephthalate) copolymer, wherein (i) the modified poly(butylene terephthalate) copolymer is derived from a first polymer comprising a poly(ethylene terephthalate) component selected from the group consisting of poly(ethylene terephthalate) homopolymers, poly(ethylene terephthalate) copolymers, and combinations thereof, in the presence of a second polymer selected from the group consisting of polyvinyl chlorides, polyvinylidene chlorides, polyamides, polylactic acid, and combinations thereof, and wherein (ii) the modified poly(butylene terephthalate) copolymer comprises at least one poly(ethylene terephthalate) component residue and a member selected from the group consisting of a second polymer selected from the group consisting of polyvinyl chlorides, polyvinylidene chlorides, polyamides, polylactic acid, and combinations thereof at least one residue derived from the second polymer, and combinations thereof; from 5 to 90 wt. % of a polycarbonate component; at least 1 wt. % of an impact modifier component.

Owner:SABIC INNOVATIVE PLASTICS IP BV

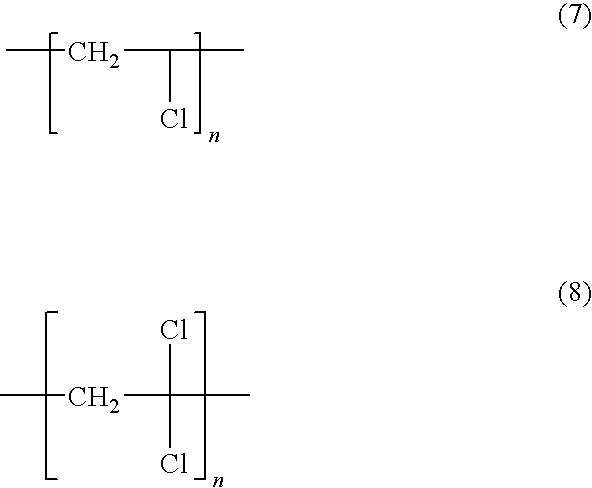

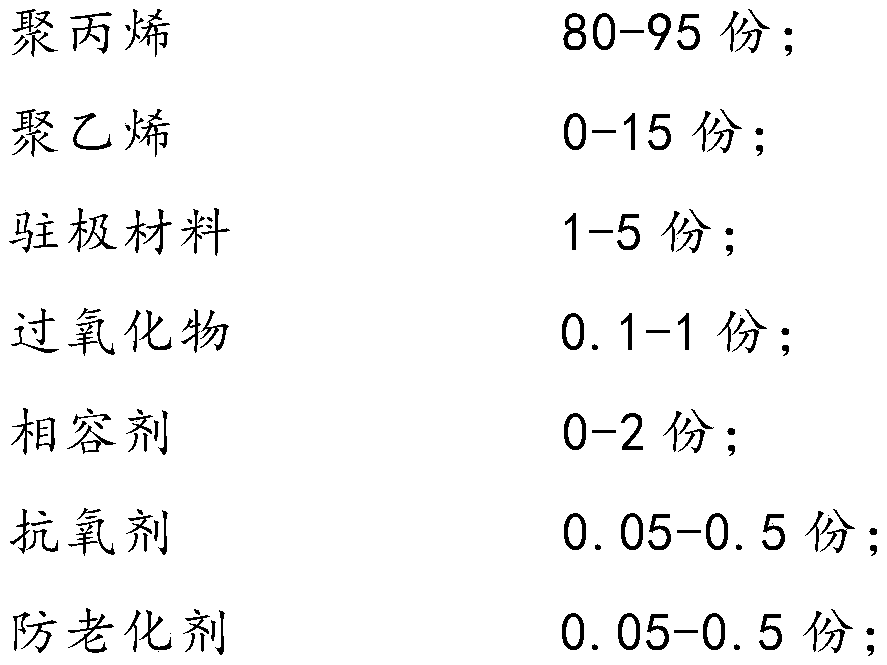

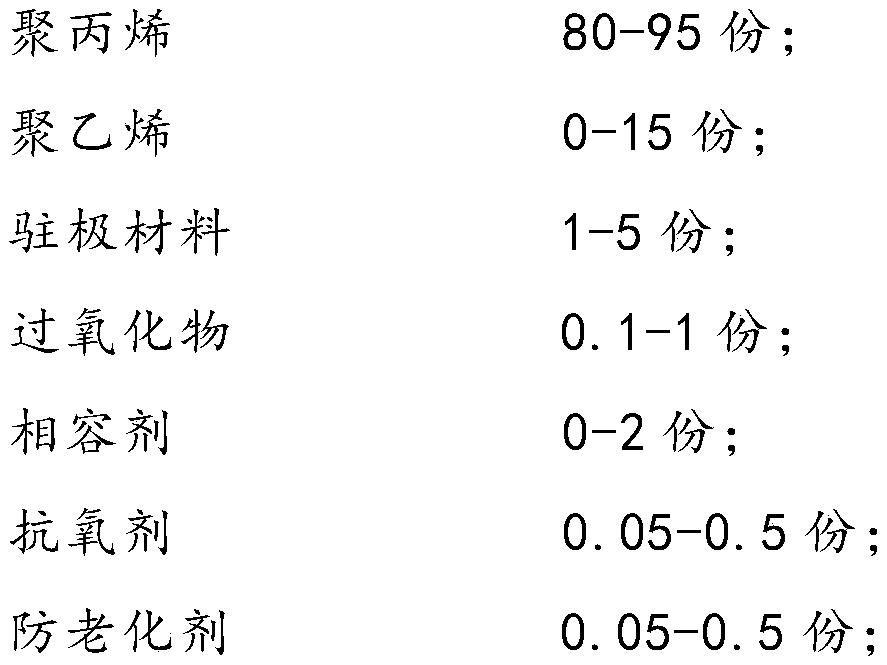

Melt-blown non-woven material with electret effect and preparation method of melt-blown non-woven material

PendingCN111533995AGood dispersionSolve the problem of liquidity differencesMelt spinning methodsNon-woven fabricsPolymer sciencePolypropylene

The invention discloses a melt-blown non-woven material which comprises the following components in parts by weight: 80-95 parts of polypropylene; 0-15 parts of polyethylene; 1-5 parts of an electretmaterial; 0.1 to 1 part of a peroxide; 0-2 parts of a compatilizer; 0.05 to 0.5 part of an antioxidant and 0.05 to 0.5 part of an anti-aging agent; the electret material is selected from one or more of fatty acid with the carbon atom number of 6-20 or salt thereof, fumed silica, titanium dioxide, calcium carbonate, talcum powder, polytetrafluoroethylene and polyvinylidene chloride. According to the melt-blown non-woven material with the electret effect and the preparation method of the melt-blown non-woven material, in the production process of the melt-blown non-woven material, the electret material is added together, so that the electret material can be better dispersed in a melt-blown resin base material, and meanwhile, the problem that the mobility difference between electret master batch and melt-blown resin is caused by adopting an electret master batch method is also solved.

Owner:朴蓝聚烯烃科技发展(上海)有限公司 +2

Method of making 1,1,1-trifluoroethane

ActiveUS7071368B1Easy to changePreparation by halogen halide additionPreparation by halogen replacementTrifluoroethaneChemistry

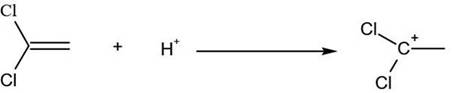

A process for producing 1,1,1-trifluoroethane (HFC-143a) which process comprises reacting hydrogen fluoride with vinylidene chloride along with one or more of 1,1,-dichloro-1-fluoroethane (HCFC-141b), 1-chloro-1,1-difluoroethane (HCFC-142b) and 1,1,1-trichloroethane (HCC-140a) in the presence of pentavalent antimony as a fluorination catalyst under conditions to produce 1,1,1-trifluoroethane (HFC-143a), generally in yields of 90% or more.

Owner:HONEYWELL INT INC

Fluoropolymer emulsions

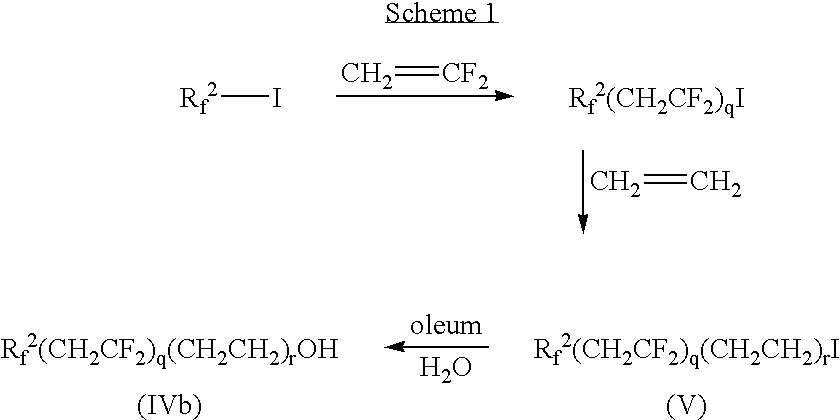

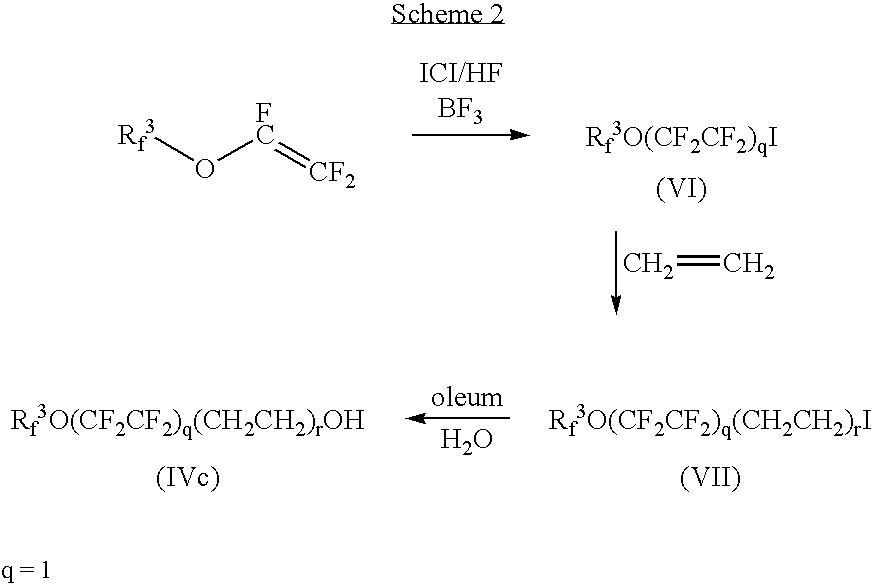

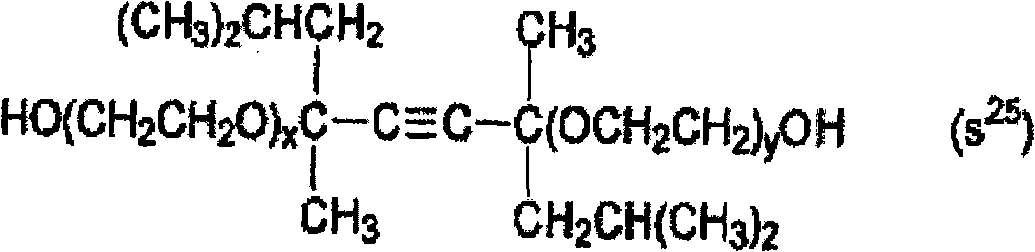

A core-shell emulsion polymer comprisingA) a core composition comprising components (a) and (b):(a) from about 40 to about 95% of styrene, alkyl substituted styrene, or alkyl (meth)acrylate; and(b) from about 5 to about 60% of vinylidene chloride, vinyl chloride, or combinations thereof; andB) a shell composition components (c) and (d):(c) from about 50 to about 85% of(I) Rf1(CH2)m Z-C(O)—C(R1)═CH2 (II) Rf2(CH2CF2)q(CH2CH2)rZ-C(O)—C(R1)═CH2, or(III) Rf3O(CF2CF2)q(CH2CH2)rZ-C(O)—C(R1)═CH2 whereinR1 is hydrogen, Cl, F or CH3;Z is —O—, —NH— or —S—;Rf1 and Rf2 are each a C4 or C6 perfluoroalkyl; andRf3 is a C2 to C7 perfluoroalkyl optionally interrupted by one to three ether oxygens; and(d) from about 15 to about 50% of styrene, alkyl substituted styrene, or alkyl (meth)acrylate,provided that i) the core composition comprises from about 20 to about 75% of the polymer; ii) when Rf1 or Rf2 has 4 carbons, R1 is CH3; and iii) when Rf3 has 2 or 3 carbons, R1 is CH3.

Owner:EI DU PONT DE NEMOURS & CO

Treatment of textile product for imparting water and oil repellency

A textile having sufficient water repellency, oil repellency and soil releasability before and after cleaning can be prepared by a method of preparing a treated textile has the steps of (1) preparing a treatment liquid containing a water- and oil-repellent agent and a stain blocking agent, (2) bringing the pH of the treatment liquid to at most 7, (3) applying the treatment liquid to the textile, (4) thermally treating the textile with steam, and (5) washing the textile with water and dehydrating the textile, wherein the water- and oil-repellent agent has a combination of (A) a fluorine-containing polymer comprising a repeat unit derived from vinyl chloride and / or vinylidene chloride, and (B) a fluorine-containing polymer free from a repeat unit derived from vinyl chloride and / or vinylidene chloride.

Owner:DAIKIN IND LTD

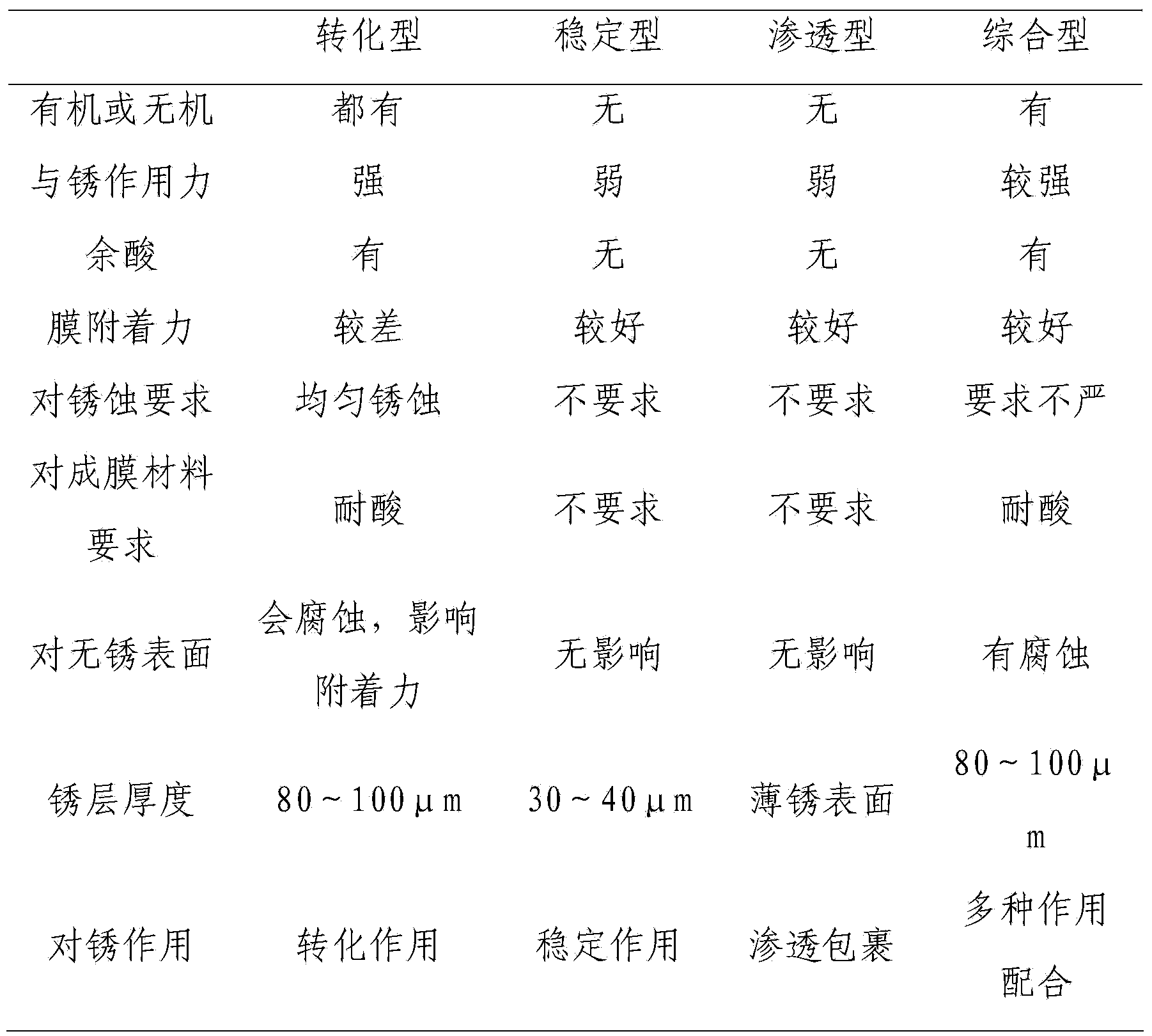

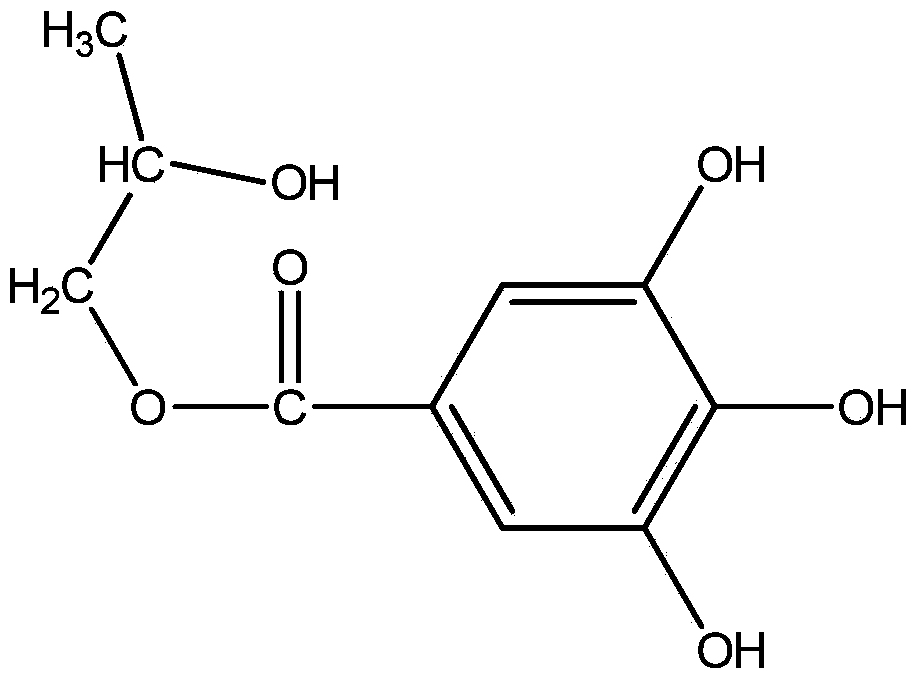

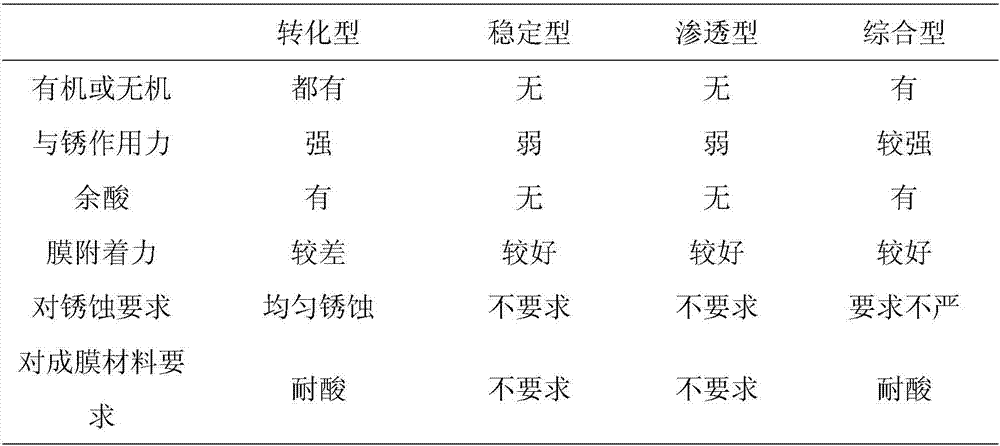

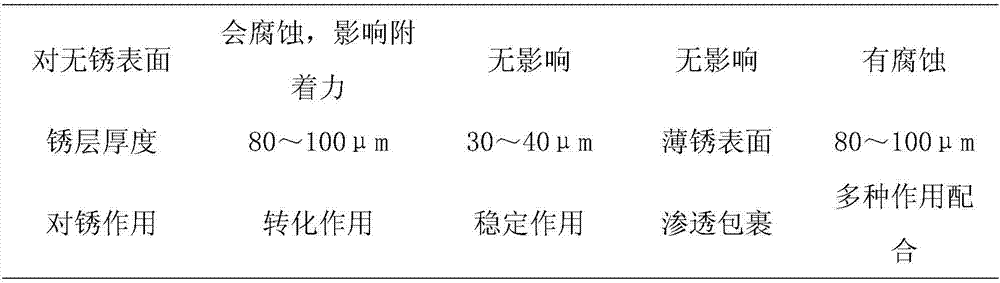

Rust transforming agent and preparation method thereof, water-based iron rust conversion coating and preparation method thereof

InactiveCN103849862AImprove water resistanceImprove stabilityAnti-corrosive paintsMetallic material coating processesWater basedGallic acid ester

The invention belongs to the technical field of a metal anti-corrosion coating, and particularly relates to a rust transforming agent and a preparation method thereof, a water-based iron rust conversion coating and a preparation method thereof. The rust transforming agent comprises a step of synthesizing 2-hydroxypropyl 3,4,5-trihydroxybenzoic acid by taking a gallic acid, 1,2-propylene glycol and a p-toluenesulfonic acid as initial raw materials, wherein the rust transforming agent contains 18.5-26.7% of gallic acid, 66.6-74% of 1,2-propylene glycol, and 6.6-7.5% of p-toluenesulfonic acid; the water-based iron rust conversion coating is prepared from a vinylidene chloride composite polymer emulsion, ethylene glycol butyl ether, filling slurry prepared in the step (1) and the rust transforming agent. The prepared rust transforming agent disclosed by the invention is good in water tolerance, strong in stability, and good in matching property with a water paint and an oil paint.

Owner:SHANDONG UNIV OF SCI & TECH

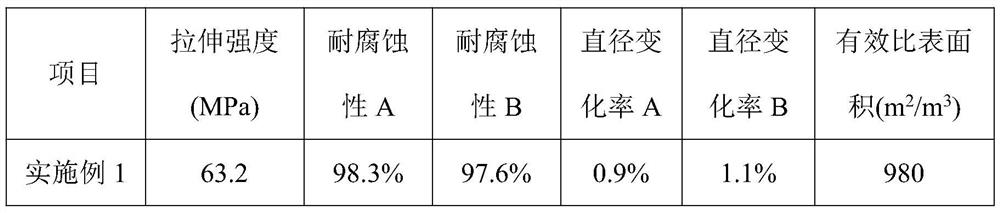

Polyvinylidene chloride-acrylate copolymer emulsion for water-based metal anti-corrosion coating and synthetic method thereof

InactiveCN107759721AImprove toughnessIncrease the degree of cross-linkingAnti-corrosive paintsChemistryEmulsion

The invention provides a polyvinylidene chloride-acrylate copolymer emulsion for a water-based metal anti-corrosion coating and a synthetic method thereof. The copolymer emulsion is prepared from, byweight, 40-50 parts of mixed monomer, 0.2-0.25 part of an initiator and 0.4-0.5 part of emulsifier, wherein the mixed monomer is prepared from 15% of acrylic ester, 5% of acrylic acid and 80% of vinylidene chloride, the initiator is prepared from potassium persulfate, and the emulsifier is prepared from 20% of sodium lauryl sulfate and 80% of 1-allyl-2-sodium hydroxy alkanesulfonate. The preparedpolyvinylidene chloride-acrylate copolymer emulsion for the water-based metal anti-corrosion coating is high in toughness and adhesive force, and good in storage stability, salt spray resistance, corrosion resistance and other comprehensive performance.

Owner:摩田材料科技(昆山)有限公司

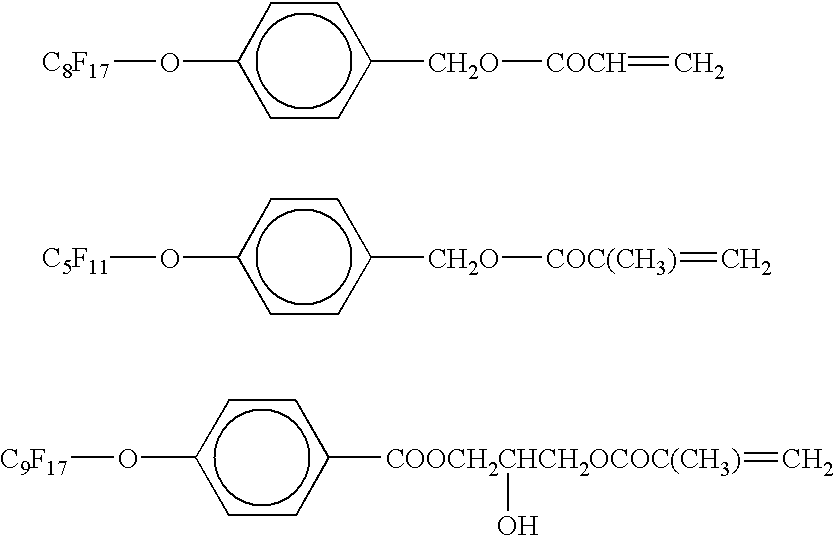

A water-and-oil repellant composition and article

InactiveCN101809112AHigh friction durabilityReduce environmental loadOther chemical processesLiquid repellent fibresPolymer scienceStructural unit

A water-and-oil repellant composition which has structural units based on a monomer having an Rf group with 6 or less carbon atoms and has a minimal amount of structural units based on a monomer having an Rf group with 8 or more carbon atoms and which, despite this, can impart water and oil repellency with excellent long-term friction resistance to the surface of an article. Also provided is an article which is reduced in environmental burden and is less apt to frictionally decrease in water and oil repellency. The water-and-oil repellant composition comprises a polymer (A) having units of a monomer (a) and units of a monomer (b) and having no units of a monomer (c), the proportion of fluorine atoms in the polymer (A) being 15-45 mass%, excluding 45 mass%, and a polymer (B) having units of a monomer (a) and having no units of a monomer (c), the proportion of fluorine atoms in the polymer (B) being 45 mass% or higher. Monomer (a): a monomer having an Rf group with 4-6 carbon atoms. Monomer (b): a monomer having C12 or higher alkyl, vinyl chloride, or vinylidene chloride. Monomer (c): a monomer having an Rf group with 8 or more carbon atoms.

Owner:AGC INC

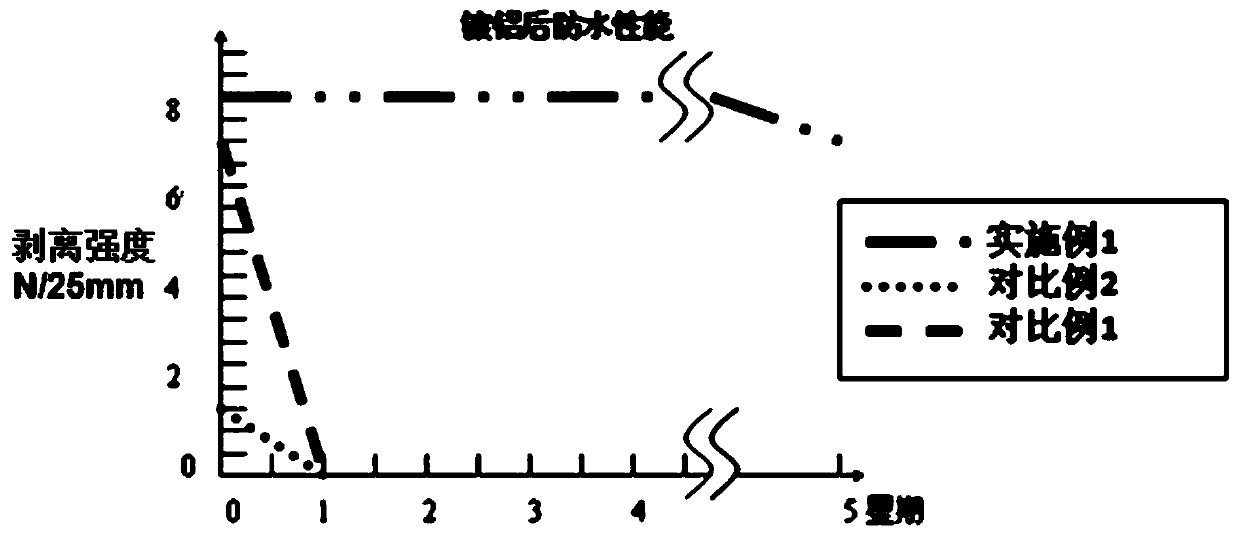

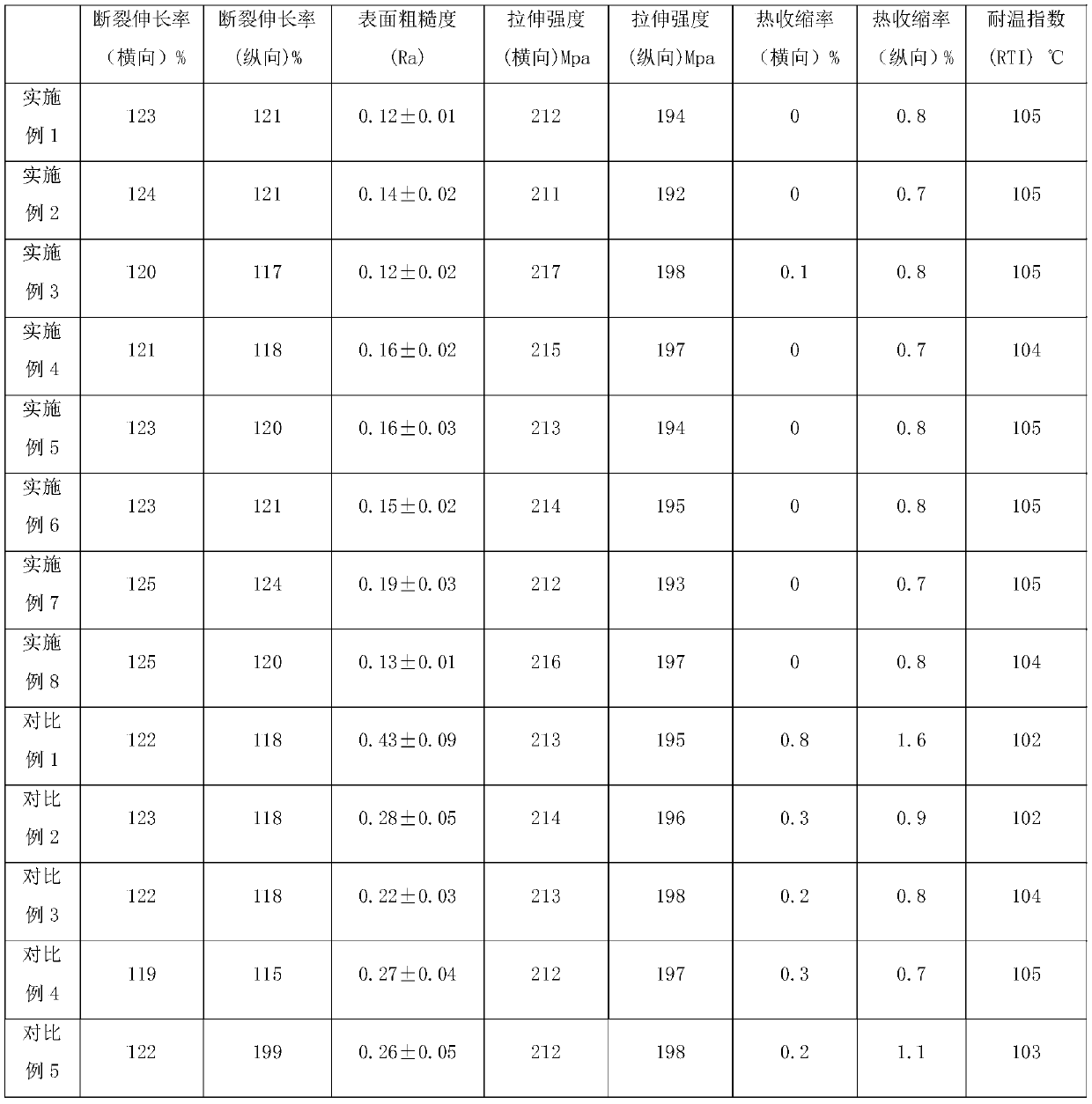

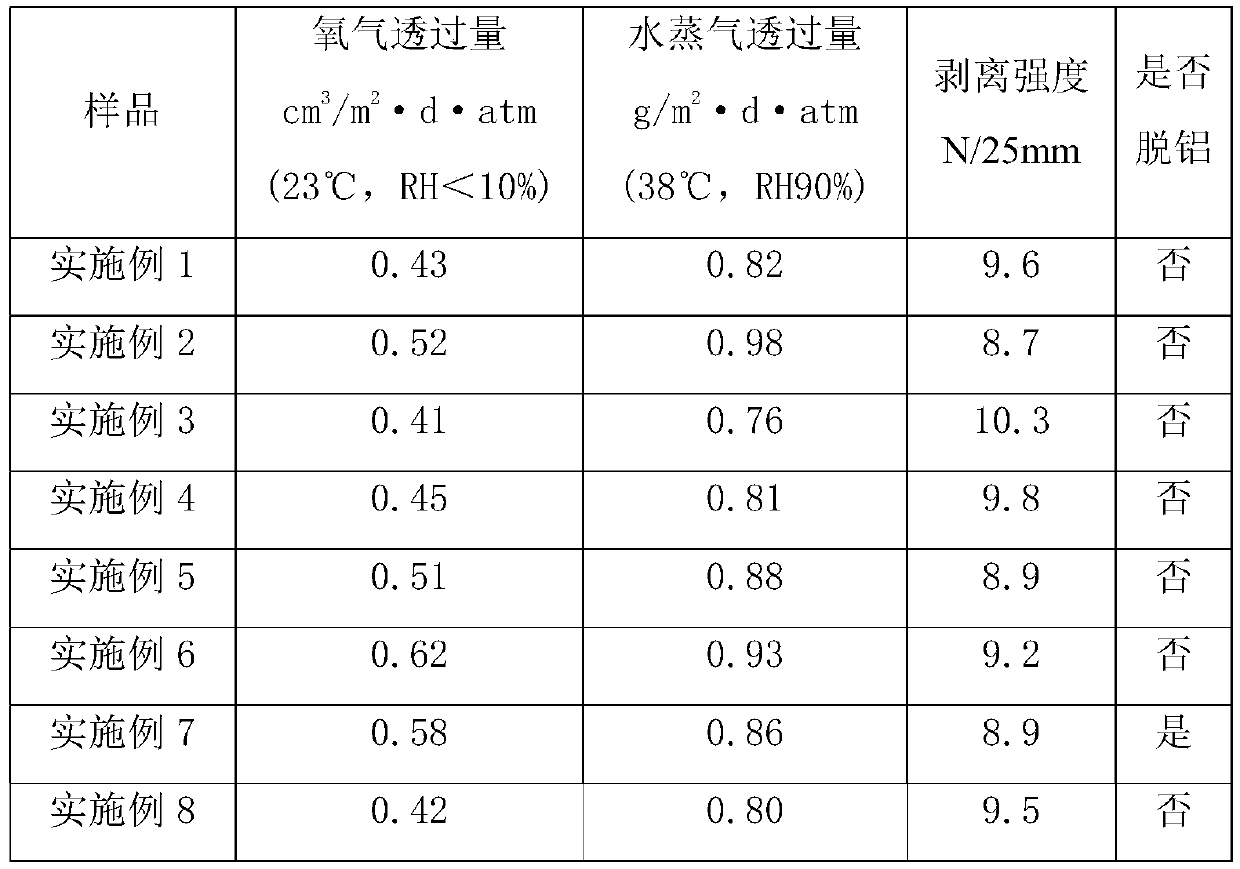

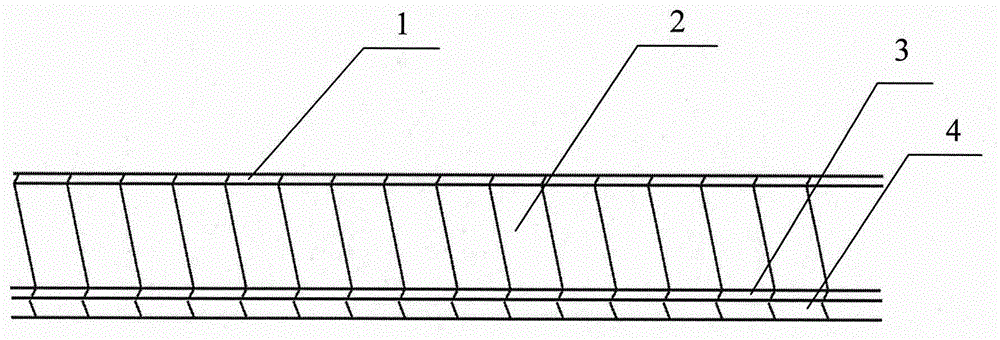

Online-coated modified biaxially-oriented polyester film and preparation method therefor

The invention provides an online-coated modified biaxially-oriented polyester film, a preparation method therefor and use of the online-coated modified biaxially-oriented polyester film. According tothe modified biaxially-oriented polyester film, a single face or both faces of a polyester base film have coatings, the coatings are obtained through coating surfaces of the polyester base film with aqueous coating liquid and then carrying out volatile drying, the aqueous coating liquid comprises water-soluble resin, a curing agent, a surfactant, chitosan and functional assistants, and the water-soluble resin is obtained through copolymerizing the following monomers: vinylidene chloride, acrylic acid, alkyl (meth)acrylate, vinyl acetate and acrylic cellulose. After aluminizing, the film provided by the invention is good in barrier property and is particularly suitable for serving as a food packaging material; meanwhile, the adhesive power between the film and an aluminum layer is high, thepeeling strength reaches 8.7N / 25mm or more; and due to high fastness of the aluminum layer, a dealuminizing phenomenon does not occur even if under high-heat high-humidity conditions, fire control potential safety hazards and harmfulness to human bodies are greatly reduced, and thus, the film has an obvious environment-friendly significance.

Owner:佛山杜邦鸿基薄膜有限公司

Water-based rust conversion priming paint and preparation method

InactiveCN107033686AImprove water resistanceImprove stabilityAnti-corrosive paintsWater basedEmulsion

The invention belongs to the technical field of metal anticorrosive coatings and relates to a water-based rust conversion priming paint and a preparation method. The water-based rust conversion priming paint comprises the components of, by weight, 30-60 parts of vinylidene chloride compound macromolecule emulsion, 20-40 parts of color filling slurry, 5-15 parts of 2-hydroxyl propyl-3,4,5-trihydroxybenzoic acid rust conversion agent, 0.05-0.1 part of antifoaming agent and 0.1-0.5 part of thickening agent. The rust conversion agent is good in water resistance, high in stability and excellent in matching with water-based and oil-based paints, and the workability, the conversion efficiency and the corrosion resistance are all relatively high.

Owner:SHANDONG UNIV OF SCI & TECH

Polymer thick film solder alloy/metal conductor compositions

This invention provides a polymer thick film conductor composition comprising (a) a solder alloy powder selected from the group consisting of (i) a tin, silver, and copper alloy powder, (ii) a tin and bismuth alloy powder, and (iii) mixtures thereof, (b) a metal selected from the group consisting of silver, copper, gold, aluminum and mixtures thereof, and (c) an organic medium comprising a resin that is a vinyl co-polymer resin of vinylidene chloride and acrylonitrile or a phenoxy resin dissolved in an organic solvent, wherein the solder alloy powder and the metal are dispersed in the organic medium.

Owner:DU PONT CHINA LTD

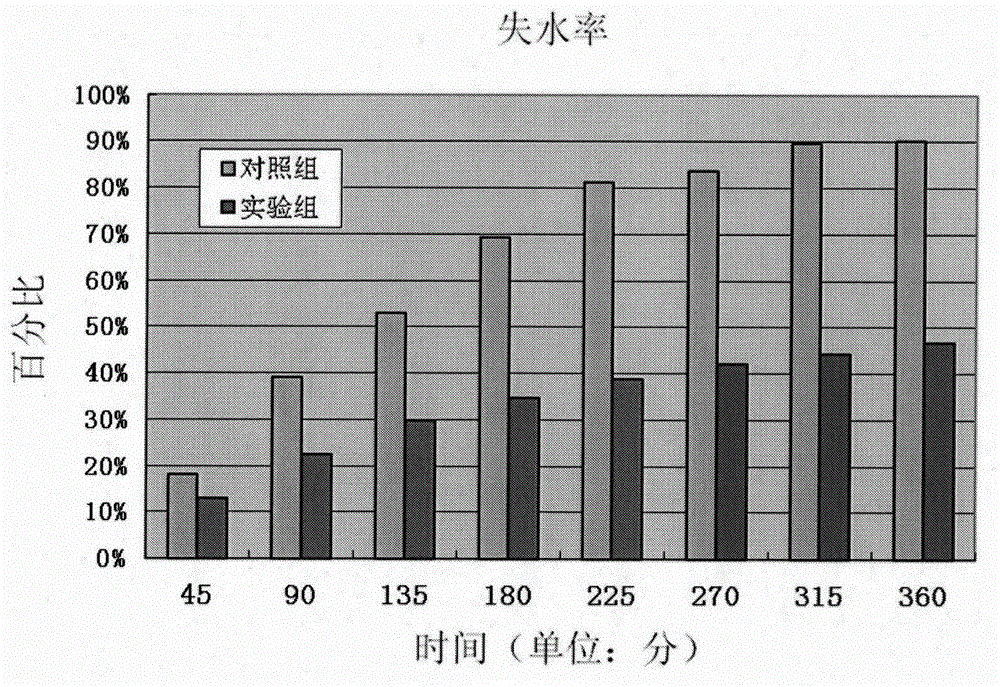

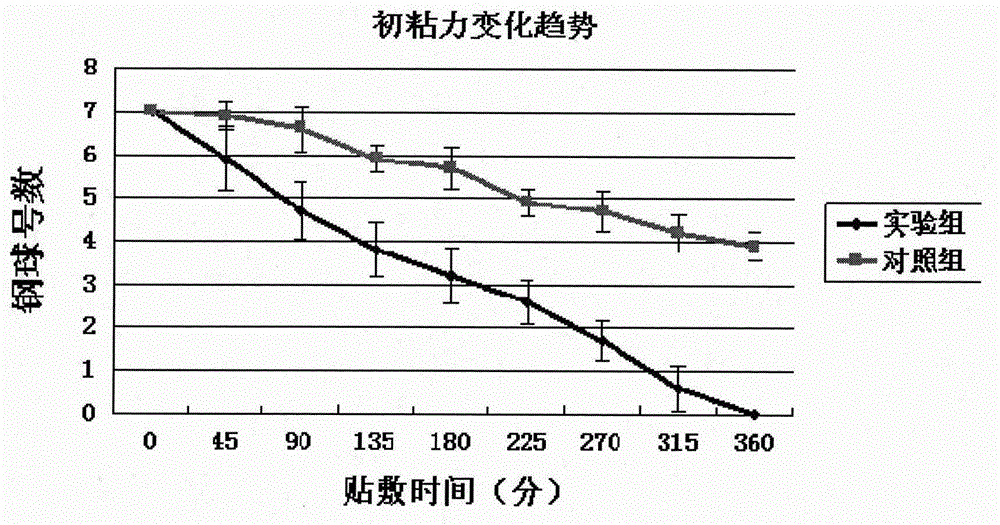

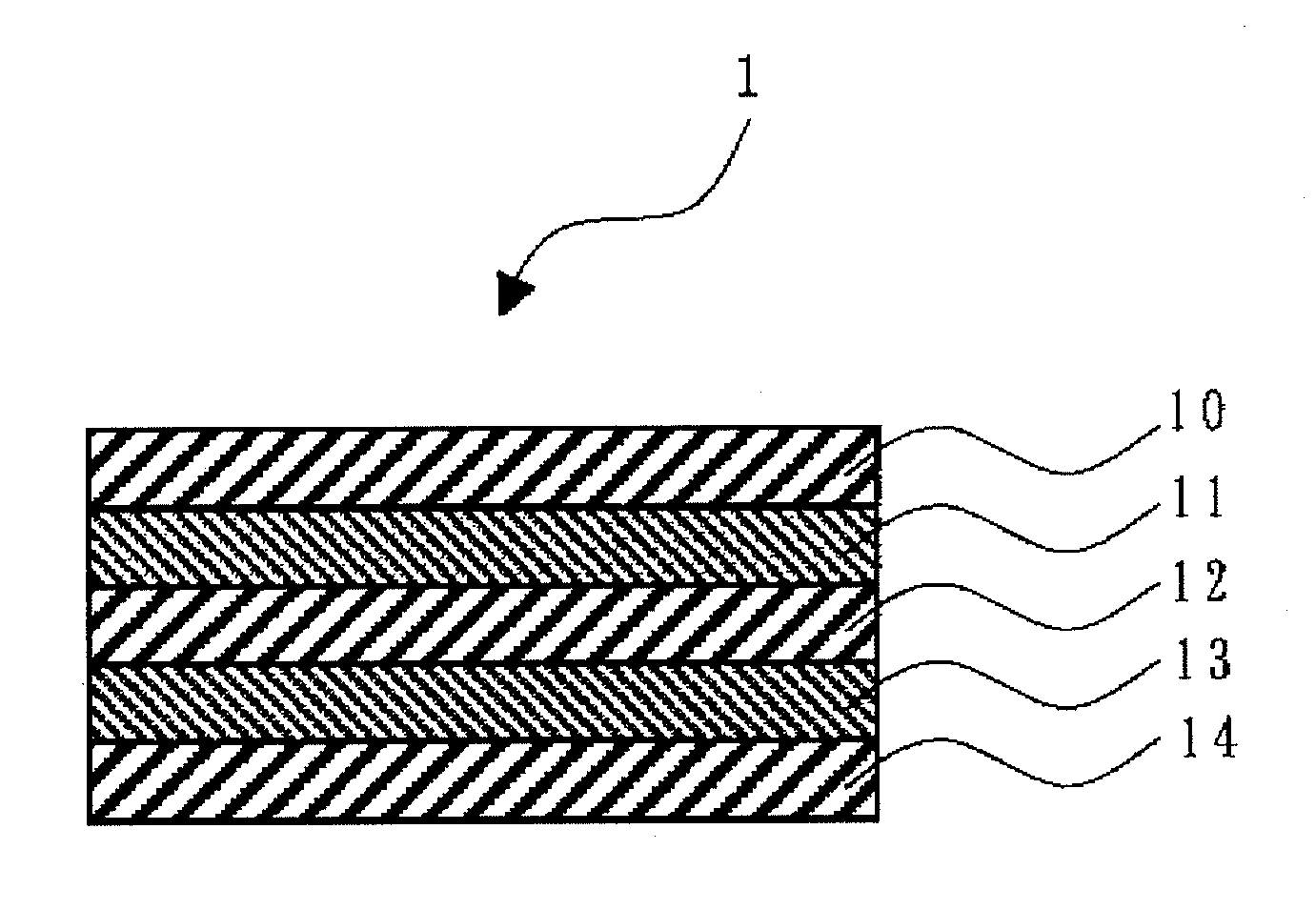

Persistent hydrogel patch

InactiveCN103933019AIncrease moisture contentWith breathable functionPharmaceutical non-active ingredientsSheet deliveryPolyesterPolymer science

The invention discloses a persistent hydrogel patch. The persistent hydrogel patch is composed of a supporting layer, a hydrogel layer and a separation layer, wherein the supporting layer is made of waterproof compound materials which are composed of waterproof materials and basic materials, the hydrogel layer is coated on the surface of the basic materials of the waterproof compound materials, the basic materials are one of non-woven fabric, knitted fabric and woven fabric, the waterproof materials are one or more of polyethylene, polyurethane, thermoplastic polyurethane, polyester, polypropylene, polyvinyl chloride, polyvinylidene chloride, ethylene-vinyl acetate monomer polymer, silicone rubber, polyimide and the like, are shaped like a film, and are compounded with the basic materials through the processes of film laminating, hot rolling, fabric and powder compounding, hot melt adhesive breathable coating and the like, and the waterproof compound materials are formed. The waterproof materials can be fluid or be compounded with the basic materials through the processes of directly coating, curtain coating and the like, and the waterproof compound materials are formed. According to the persistent hydrogel patch, water in the hydrogel layer can be effectively prevented from being scattered through the supporting layer, and the purposes of lengthening the time of keeping good adhesion performance of the hydrogel layer and increasing the transdermal absorption rate are achieved.

Owner:HANGZHOU JIERSI BIOTECH CO LTD

Vinylidene chloride polymer compositions and food casings made therefrom

InactiveUS20050255263A1Improve meat adhesionThermoplastic sausage casingsFlexible coversChlorideAlpha-olefin

The present invention is a poly(vinylidene chloride) interpolymer composition comprising (1) a copolymer of an alpha olefin and an alkyl ester of an unsaturated carboxylic acid and (2) an interpolymer of vinylidene chloride and vinyl chloride, the copolymer being present in an amount effective to improve meat adhesion of a food casing made from the interpolymer composition having the copolymer as compared with a composition having the same proportions of components as the interpolymer composition but without the added copolymer (hereinafter effective amount). Preferably, the copolymer comprises ethylene and at least one alkyl ester of an unsaturated carboxylic acid. The invention is also a process for preparing a thermoplastic food casing which comprises adding an effective amount of a copolymer of an alpha olefin and an alkyl ester of an unsaturated carboxylic acid to a an interpolymer of vinylidene chloride and vinyl chloride to improve meat adhesion of the food casing. Additionally, the invention is a film comprising an interpolymer of vinylidene chloride and vinyl chloride and an effective amount of a copolymer of an alpha olefin and an alkyl ester of an unsaturated carboxylic acid. The film is preferably used in applications for contacting meat. Additionally, the invention is a combination of a film comprising an interpolymer of vinylidene chloride and vinyl chloride and an effective amount of a copolymer of an alpha olefin and an alkyl ester of an unsaturated carboxylic acid and, adjacent thereto or in contact therewith, a fatty substance, preferably a meat having a fat content, meat product having fat content, or other food having a fat content. In another aspect, the invention is a package useful for meats or other fatty substances comprising an interpolymer of vinylidene chloride and vinyl chloride and an effective amount of a copolymer of an alpha olefin and an alkyl ester of an unsaturated carboxylic acid wherein the package is designed for contact of interpolymer of vinylidene chloride with the meat or fatty substance. In another aspect, the invention is a sausage casing having a film comprising an interpolymer of vinylidene and chloride vinyl chloride and an effective amount of a copolymer of an alpha olefin and an alkyl ester of an unsaturated carboxylic acid. In yet another aspect, the invention is the use of a vinylidene chloride interpolymer composition comprising and interpolymer of vinylidene chloride and vinyl chloride and an effective amount of at least one copolymer of an alpha olefin and an alkyl ester of an ethylenically unsaturated carboxylic acid in a composition suitable for making a film, the resulting film, a molded article, a package, in each case preferably suitable for contacting or containing a fatty substance or food, preferably in a sausage casing.

Owner:LEE ERIC K C +1

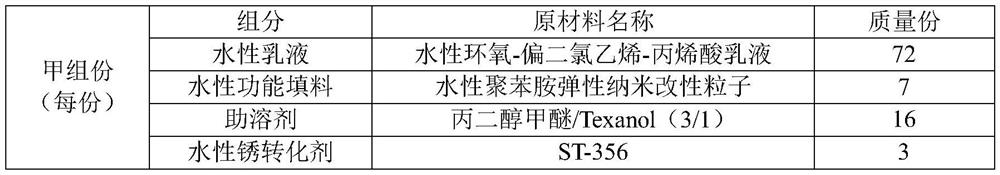

Water-based rust conversion anticorrosive coating for steel structures, and preparation method thereof

ActiveCN111662603AImprove corrosion resistanceImprove air tightnessConjugated diene hydrocarbon coatingsAnti-corrosive paintsFirming agentPolyaniline

The invention relates to a water-based rust conversion anticorrosive coating for steel structures and a preparation method thereof, and belongs to the technical field of anticorrosive coatings. The water-based rust conversion anticorrosive coating is composed of a component A and a component B in a mass ratio of (5-10): 1; the component A comprises, by weight, 50-80 parts of a water-based epoxy-vinylidene chloride-acrylic emulsion, 5-10 parts of water-based polyaniline elastic nano-modified particles, 10-20 parts of a water-based cosolvent, 2-3 parts of a water-based rust conversion agent, 0.4-1.2 parts of a water-based defoaming agent, 0.2-0.5 part of a water-based thixotropic agent and 10-15 parts of deionized water; and the component B comprises, by weight, 70-100 parts of a water-basedmodified amine curing agent and 0.5-2 parts of a water-based penetrating agent. The coating prepared by the invention has vinylidene chloride resin shielding property and epoxy resin salt spray resistance, and the addition of the water-based polyaniline elastic nano-modified particles improves the corrosion resistance of the coating on the rusty metal surface.

Owner:洛阳双瑞防腐工程技术有限公司

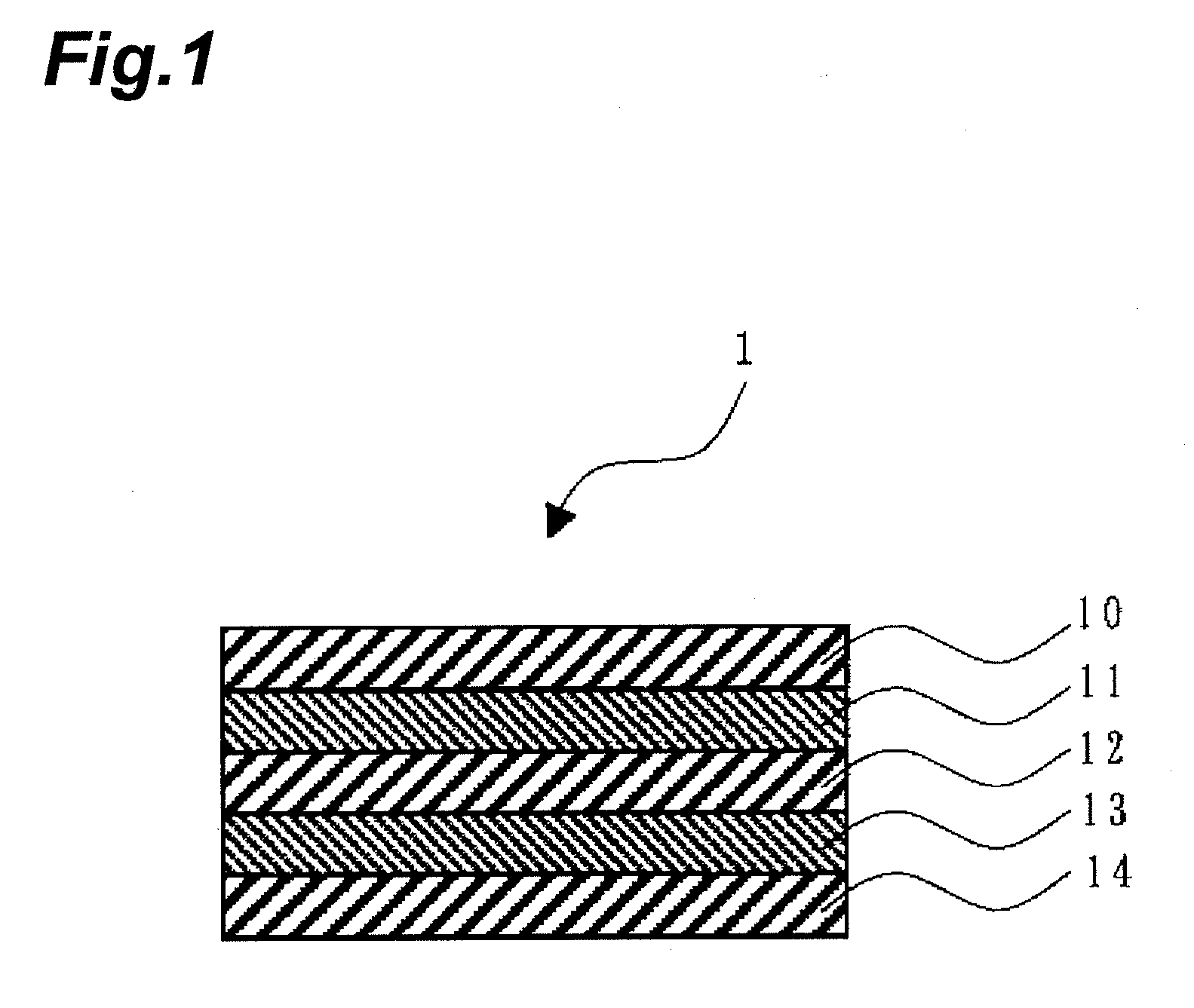

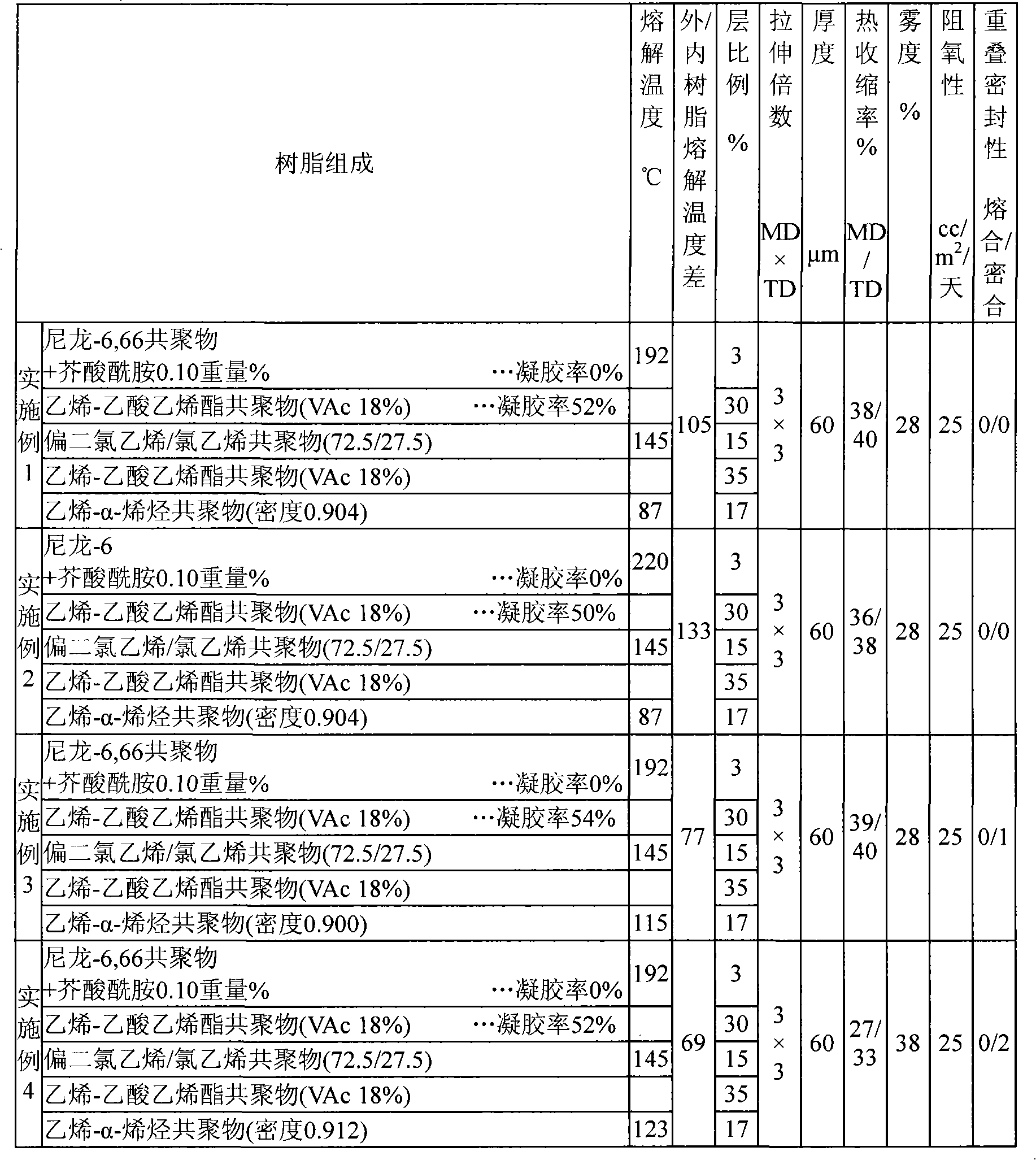

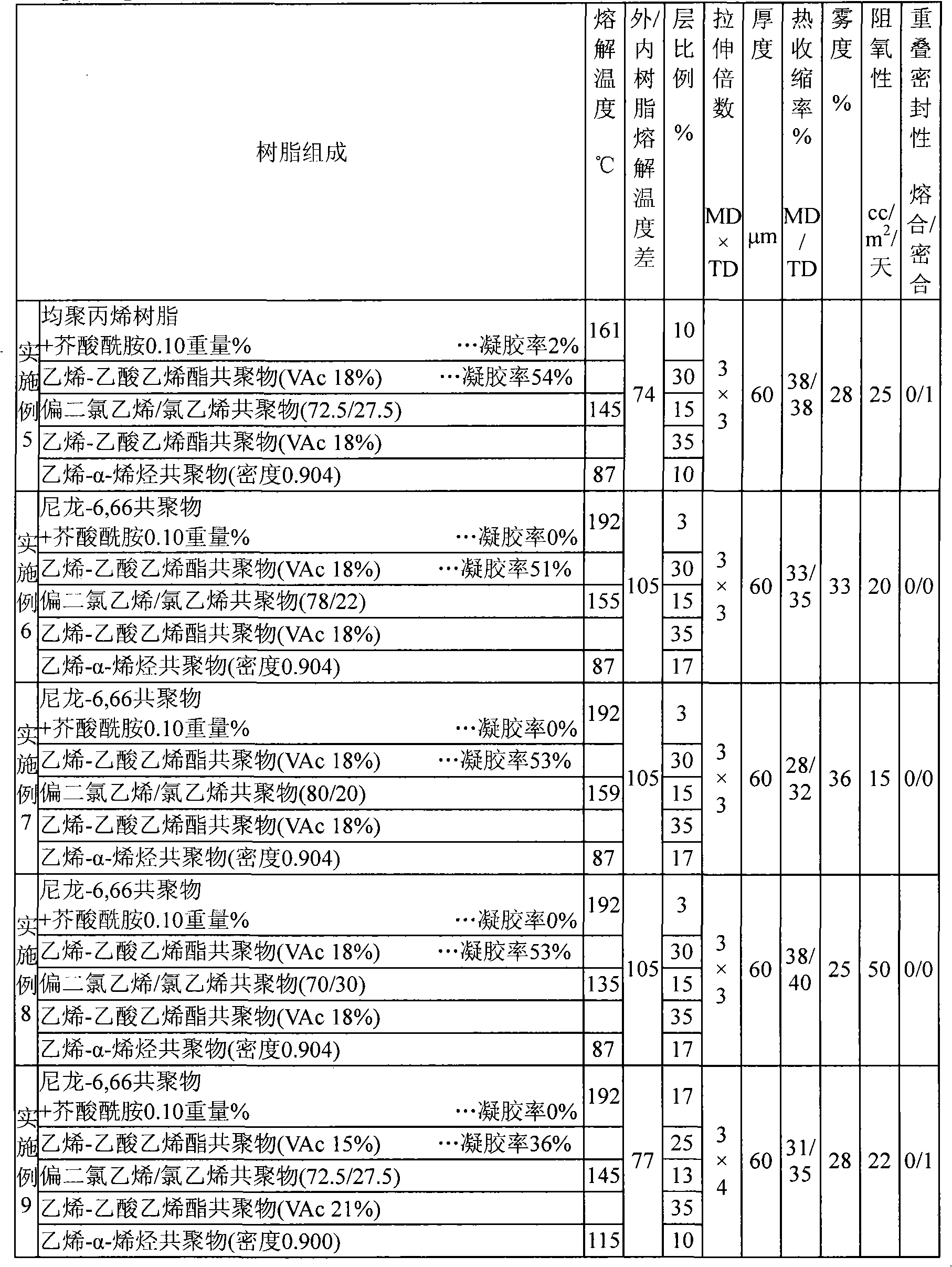

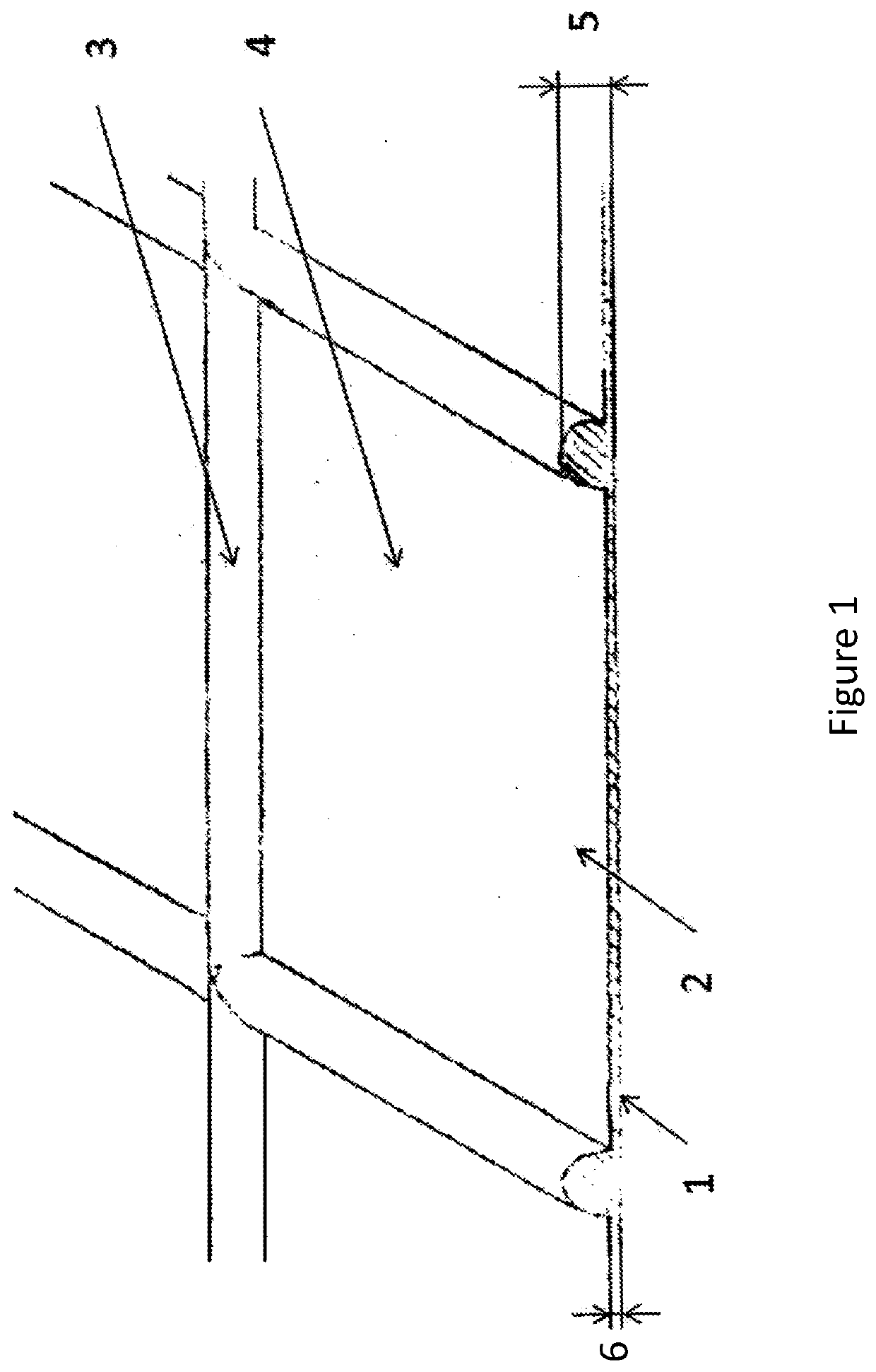

Stretched laminated film and bag

InactiveUS20100086711A1StructuredBeautifully conductedWrappers shrinkageFlexible coversSurface layerEngineering

A stretched laminated film and bag is provided, in which a packaging operation in thermal shrinkage packaging is effectively performed without the occurrence of fusion and the like between margins when sealing via heat-sealing with a margin portion of an adjacent bag in a layered state, and without of bag whitening in a thermal shrinkage process thereafter. Specifically, a stretched laminated film has at least four layers of: a surface layer (A), an adhesive layer (A), a barrier layer, and a surface layer (B) sequentially laminated in order thereof, in which the melting temperature of the surface layer (A) is only increased no less than 65° C. to no more than 150° C. higher than the melting temperature of the surface layer (B), and the barrier layer is composed of a vinylidene chloride copolymer, and the melting temperature of the barrier layer is no less than 130° C. to less than 160° C.

Owner:ASAHI KASEI CHEM CORP

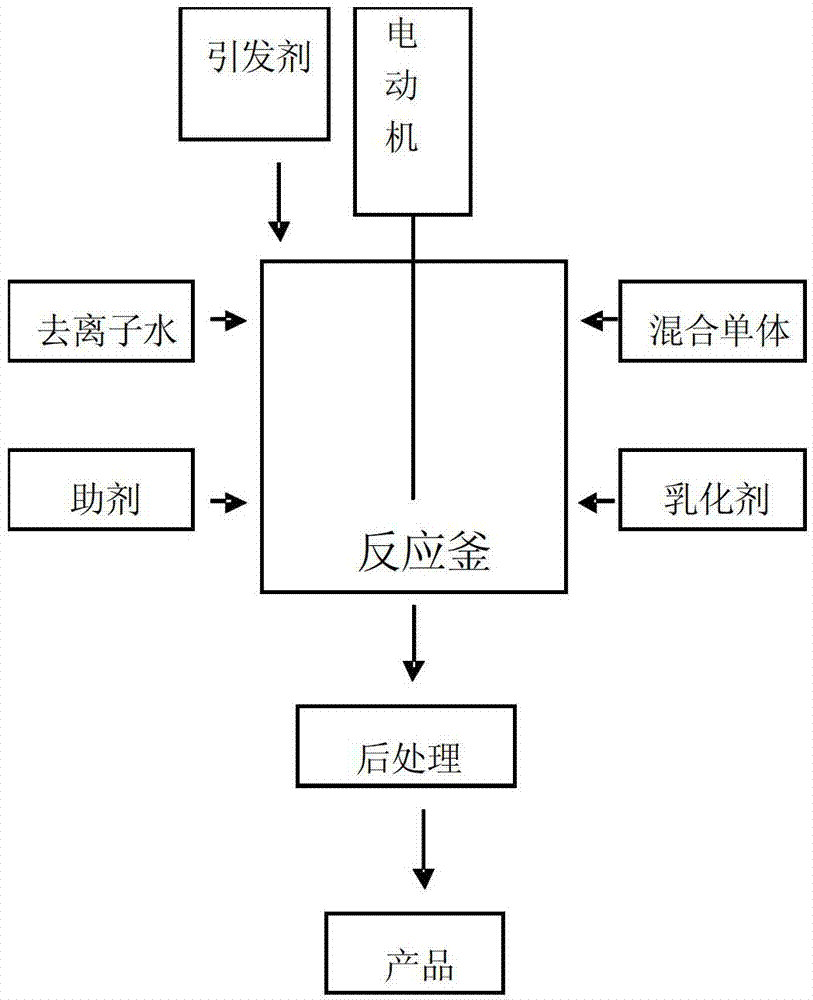

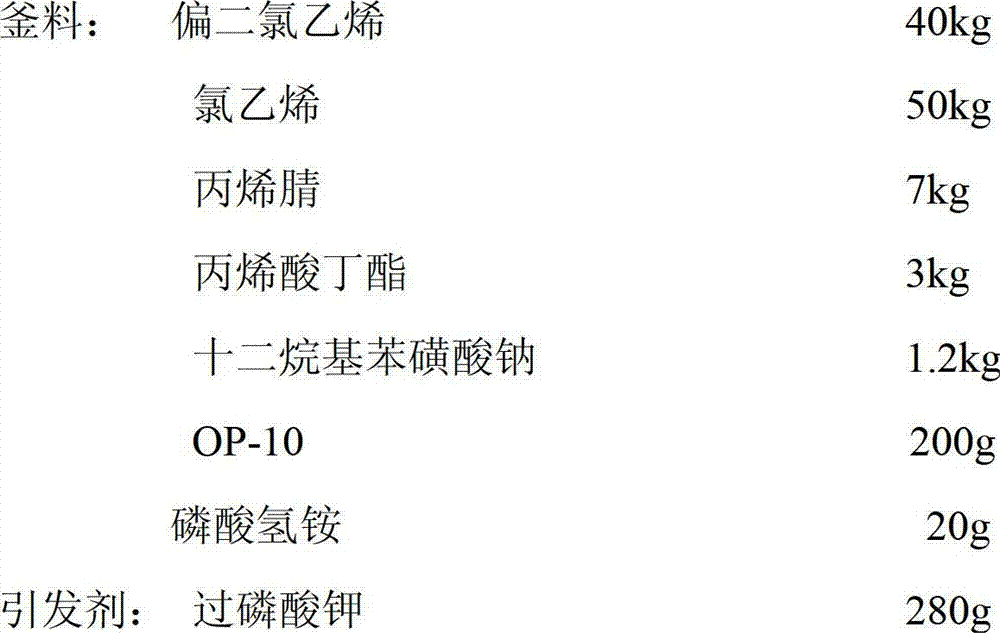

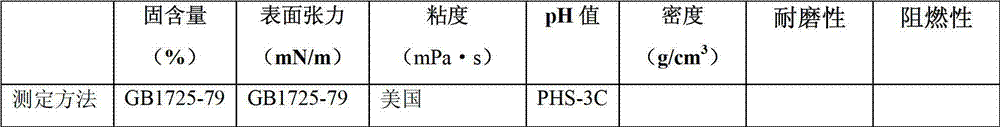

PVDC copolymer emulsion for wear-resistant water-based floor paint as well as preparation method and application thereof

ActiveCN103044601APromote environmental protectionImprove wear resistanceCoatingsWater basedPolymer science

The invention discloses a PVDC (polyvinyl dichloride) copolymer emulsion for a wear-resistant water-based floor paint, as well as a preparation method and an application thereof, and solves the problems of poor wear resistance, no flame resistance and the like. The wear-resistant water-based floor paint is prepared by taking a certain amount of vinylidene chloride, vinyl chloride, vinyl cyanide and acrylic ester as mixed monomers and carrying out emulsion polymerization. Due to the existence of chloride atoms, the water-based floor paint prepared with the PVDC copolymer emulsion is good in environmental friendliness, high in wear resistance and excellent in flame resistance; and a floor coated with the floor paint is better in safety, the product quality is improved and the product is popular with consumers.

Owner:海南聚能创新服务有限公司

Stretched laminated film and bag

InactiveCN101610904AExcellent overlapping sealabilityReliable Packaging OperationsFlexible coversWrappersPolymer scienceMelt temperature

A stretched laminated film and bag is provided, in which a packaging operation in thermal shrinkage packaging is effectively performed without the occurrence of fusion and the like between margins when sealing via heat-sealing with a margin portion of an adjacent bag in a layered state, and without of bag whitening in a thermal shrinkage process thereafter. Specifically, a stretched laminated film has at least four layers of: a surface layer (A), an adhesive layer (A), a barrier layer, and a surface layer (B) sequentially laminated in order thereof, in which the melting temperature of the surface layer (A) is only increased no less than 65 DEG C to no more than 150 DEG C higher than the melting temperature of the surface layer (B), and the barrier layer is composed of a vinylidene chloride copolymer, and the melting temperature of the barrier layer is no less than 130 DEG C to less than 160 DEG C.

Owner:ASAHI KASEI CHEM CORP

Polyvinylidene chloride rust-turning rustproof water-based paint and preparation technology thereof

ActiveCN109504193AAbundant raw materialsEasy to manufactureAnti-corrosive paintsWater basedMineral oil

The invention relates to a polyvinylidene chloride rust-turning rustproof water-based paint and a preparation technology thereof and belongs to the technical field of chemical coatings. The polyvinylidene chloride rust-turning rustproof water-based paint is characterized by comprising the following components in parts by weight: 50-75 parts of polyvinylidene chloride emulsion, 3-15 parts of modified emulsion, 2.0-5.0 parts of auxiliaries, 0.1-0.5 part of organic silicon flatting agent, 0.1-0.5 part of mineral oil de-foaming agent, 3.0-20 parts of rust-turning agent and 0.5-2.0 parts of chloride ion inhibitor. The processing steps are as follows: adding polyvinylidene chloride emulsion, modified emulsion and auxiliaries at mass ratio into a preparation container and stirring; adding rust-turning agent solution and chloride ion inhibitor solution; continuing to stir after solution is fully added, and then filtering. The invention provides a physically modified universal PVDC emulsion anda technical method. The modified emulsion completely has the basic performance of metallic paint, namely, excellent rustproof performance, and is especially suitable for preparing a rust-turning rustproof water-based paint.

Owner:淄博菲克氟碳材料技术有限公司

Article comprising a water-based top-coat

InactiveUS20190127594A1Improve ink adhesionImprove paint adhesionAcid polymer adhesivesEster polymer adhesivesPolyesterWater based

An article includes a substrate and a top-coat having a first side disposed on and in direct contact with the substrate and a second side that is outermost and exposed to the environment. The top-coat includes a first polymer chosen from acrylic polymers, acrylonitrile butadiene, butyl rubber, cellulose acetate, cellulose butyrate, epoxy resins, ethylene-vinyl acetate copolymers, modified ethylene-vinylacetate, vinyl acetate copolymers, ethylene-(meth)acrylic acid ionomers, vinylidene chloride copolymers, ethylene-(meth)acrylate copolymers, polyesters, natural rubber, neoprene, phenolic polymers, polyurethanes, polyvinyl acetate, polyvinyl alcohol, styrene butadiene rubber, casein, dextrin, starch, polysaccharides, copolymers of two or more thereof and combinations of two or more thereof; and combinations of any two or more thereof, a second polymer different than the first polymer and chosen from ethylene-acrylic acid copolymers, oxidized polyethylenes, ethylene-vinyl acetate copolymers, oxidized ethylene-vinyl acetate copolymers, maleated polyolefins, homopolymers of polyethylene, homopolymers of polypropylene, and combinations of any two or more thereof, and water.

Owner:HONEYWELL INT INC

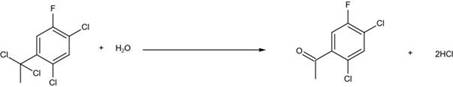

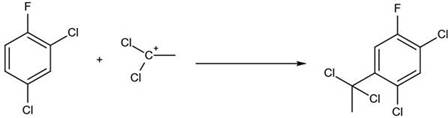

Preparation method of 2, 4-dichloro-5-fluoroacetophenone

ActiveCN113248353AReduce usageReduce dosageCarbonyl compound preparation by hydrolysisHalogenated hydrocarbon preparationOrganic layerEthyl group

The invention provides a preparation method of 2, 4-dichloro-5-fluoroacetophenone. The method comprises the following steps: by taking 2, 4-dichlorofluorobenzene as a raw material, carrying out Friedel-Crafts reaction on 2, 4-dichlorofluorobenzene and vinylidene chloride in the presence of anhydrous aluminum chloride and protonic acid at the same time to generate 1-(1, 1-dichloroethyl)-2, 4-dichloro-5-fluoroacetophenone benzene, carrying out hydrolysis reaction on the intermediate product under the catalysis of Lewis acid to generate 2, 4-dichloro-5-fluoroacetophenone and hydrogen chloride, adding a proper amount of water for layering after the reaction is finished, and rectifying an organic layer to obtain the product. According to the method, the cost of raw materials and auxiliary materials is greatly reduced, the post-treatment pressure is relieved, the yield can reach 85% or above, and the method belongs to the technical field of organic chemical industry.

Owner:SHANDONG GUOBANG PHARMA +1

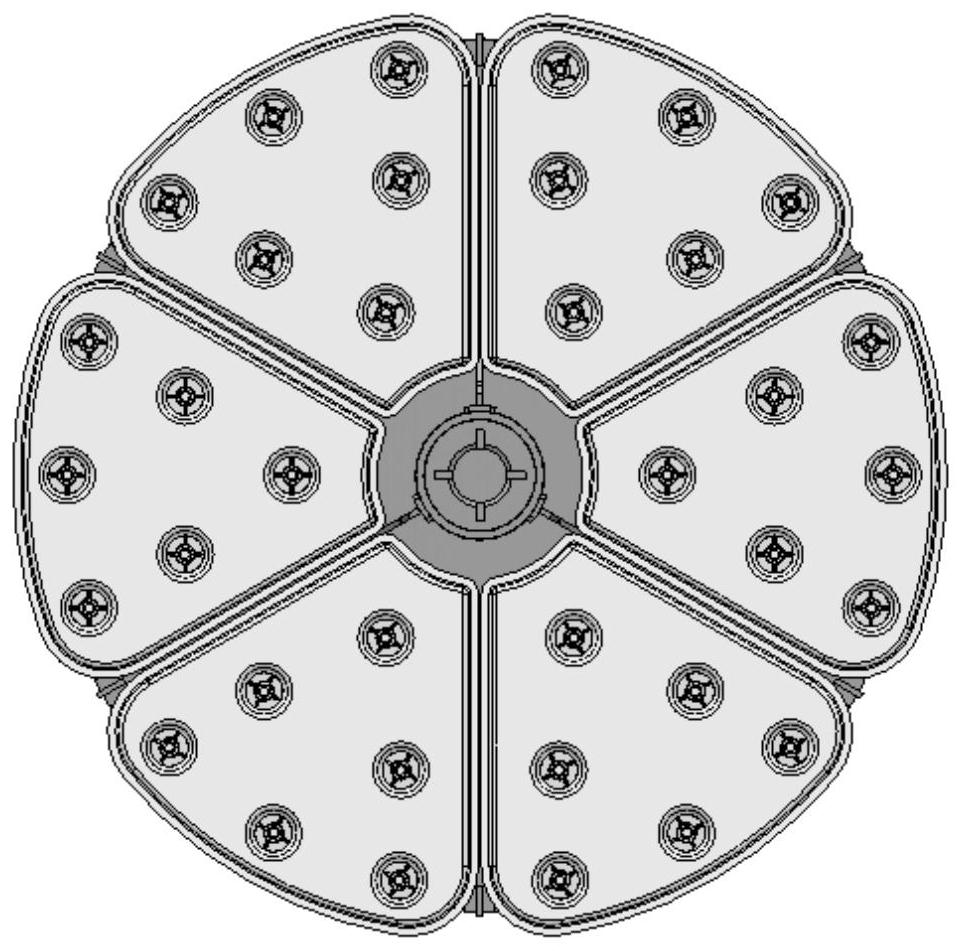

Modified PVDC polymer as well as preparation method and application thereof

ActiveCN113061206AImprove machinabilityImprove mechanical propertiesTreatment using aerobic processesSustainable biological treatmentCellulosePolymer science

The invention relates to a modified PVDC polymer. Monomers of the modified PVDC polymer comprise vinylidene chloride, dichloroethylene, glycidyl methacrylate and a cationic monomer, the modified PVDC polymer is obtained through a suspension polymerization method, and an adopted dispersing agent is a compound of water-soluble cellulose and polyvinylpyrrolidone. The prepared PVDC polymer is moderate in molecular weight distribution, and non-uniformly distributed chain segments can play a role in internal plasticization. The biological rotating disc prepared by the invention is waterproof and corrosion-resistant, the phenomena of disintegration, corrosion and the like cannot occur when the biological rotating disc is used in wastewater treatment under a wide pH condition for a long time, and the mechanical strength is basically not reduced. When the modified PVDC polymer disclosed by the invention is used for preparing a biological rotating disc material, a plasticizer does not need to be added, so that thermal decomposition caused by adding the plasticizer in a processing process is avoided; on the other hand, the stability of the biological rotating disc in water is also enhanced.

Owner:青海洁神环境科技股份有限公司

Deep drawing heat shrinkable multilayer film and method of manufacturing the same

InactiveUS7959995B2Excellent gas barrier performanceTight fitnessWrappers shrinkageShrinkage connectionsMultilayer membranePolymer science

A deep drawing heat shrinkable multilayer film includes: an intermediate layer made of a vinylidene chloride copolymer resin (a); and a resin layer made of a first thermoplastic resin (b) layered on at least one surface of the intermediate layer. The multilayer film has hot water shrinkabilities in longitudinal and transverse directions at a temperature of 90° C. range from 3% to 35% respectively.

Owner:KUREHA KAGAKU KOGYO KK

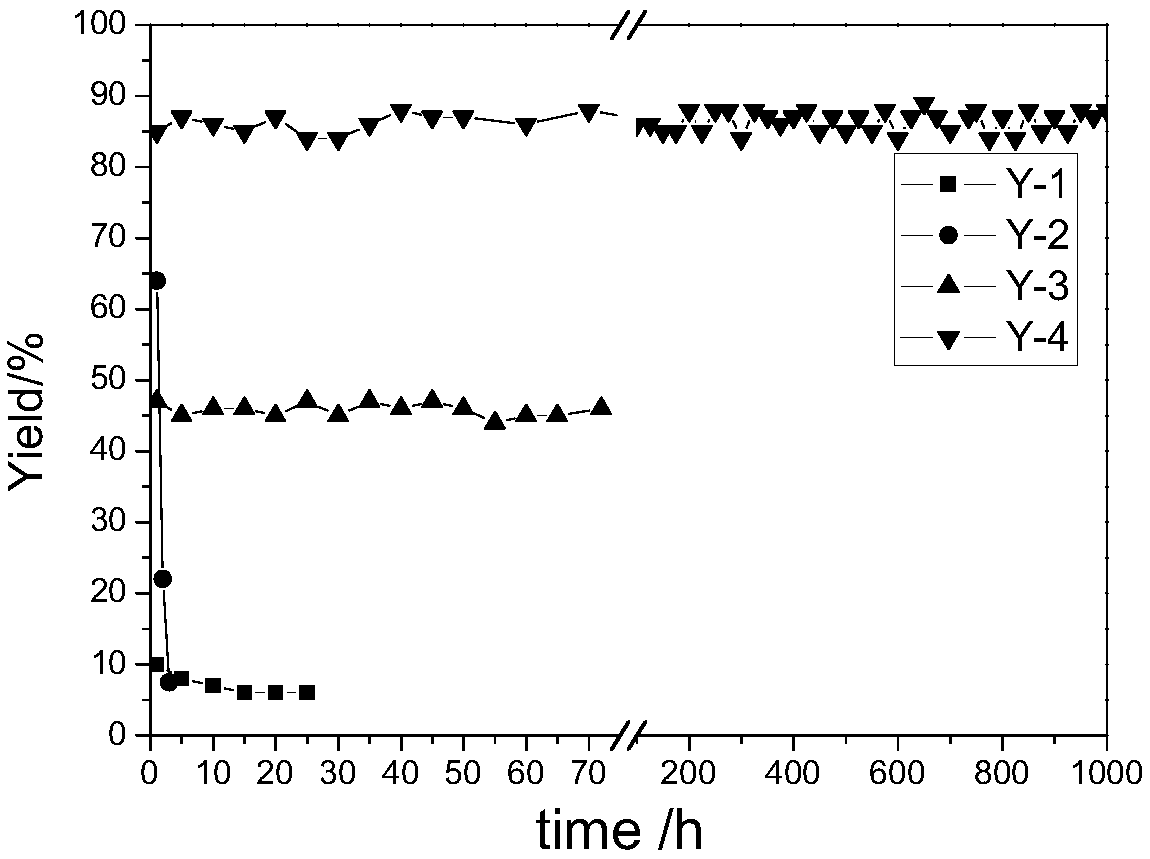

Hydrogen chloride resistant basic catalyst, preparation method and application

InactiveCN108837845AExtend your lifeExcellent resistance to hydrogen chloridePreparation by hydrogen halide split-offOrganic-compounds/hydrides/coordination-complexes catalystsGas phaseHigh activity

The invention discloses a hydrogen chloride resistant basic catalyst, a preparation method and application. The basic catalyst comprises a carrier and an active component loaded on the carrier, wherein the carrier is selected from one in SiO2, gamma-Al2O3, SBA-15, active carbon, ZSM-5, MCM-22 and silica aerogel; the active component is selected from one or a combination of more in ionic liquid taking chloride ion as anion; the loading amount of the ionic liquid is 0.1 to 40 percent. The invention provides application of the basic catalyst to reaction in which vinylidene chloride is prepared from 1. 1.2-methyl chloroform gas phase dehydrochlorination. The basic catalyst has the advantages of long service life and high activity.

Owner:ZHEJIANG UNIV OF TECH

Poly(butylene terephthalate) composition, preparation method, and products thereof

A composition comprising: 5-90wt.% modified poly(butylene terephthalate) copolymer, wherein (i) the modified poly(butylene terephthalate) copolymer Derived from a first polymer comprising a poly(ethylene terephthalate) component in the presence of a second polymer selected from the group consisting of poly(ethylene terephthalate) (ethylene glycol formate) homopolymer, poly(ethylene terephthalate) copolymer, and combinations thereof, the second polymer being selected from the group consisting of polyvinyl chloride, polyvinylidene chloride, polyamide, polylactic acid , and combinations thereof, and wherein (ii) said modified poly(butylene terephthalate) copolymer comprises the residue of at least one poly(ethylene terephthalate) component and selected from The second polymer, residues derived from the second polymer, and combinations thereof; 5 to 90 wt.% of the polycarbonate component; at least 1 wt.% of the impact modifier component, the second The polymer is selected from polyvinyl chloride, polyvinylidene chloride, polyamide, polylactic acid, and combinations thereof.

Owner:SABIC INNOVATIVE PLASTICS IP BV

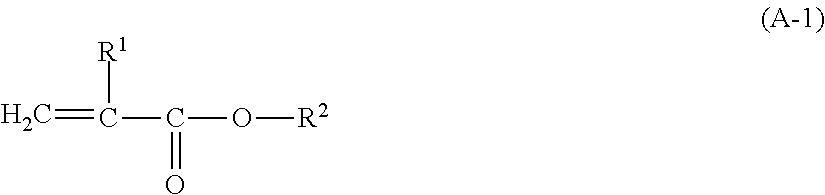

Non-fluorinated polymer, water repellent agent composition, water-repellent fiber product, and method for producing water-repellent fiber product

ActiveUS20180215848A1Good storage stabilityImprove textureOther chemical processesLiquid repellent fibresMethacrylateFiber

The non-fluorinated polymer includes a constituent unit derived from a (meth)acrylic acid ester monomer (A) represented by the following General Formula (A-1); and at least one monomer (E) from between vinyl chloride and vinylidene chloride:wherein in Formula (A-1), R1 represents a hydrogen or a methyl group; and R2 represents a monovalent hydrocarbon group having 12 or more carbon atoms which may have a substituent.

Owner:NICCA CHEM COMPANY +1

Polyvinylidene chloride compositions and their use in monofilament structures

ActiveUS8309634B2Crystallize fastShort reaction timeCeramic shaping apparatusMonocomponent synthetic polymer artificial filamentPolymer sciencePlasticizer

The present invention includes a monofilament obtainable by extruding a composition comprising: (a) at least one vinylidene chloride polymer / methyl acrylate interpolymer having at most about 6 weight percent methyl acrylate mer units in the polymer; and (b) at least about three weight percent total plasticizer, of which about 0.5 weight percent based on total composition weight is an epoxy plasticizer or combination thereof through a die such that monofilament is formed. Optionally, and preferably in extruders wherein the composition of (a) and (b) exhibits less uniformity in extrusion than is desired, at least one methacrylic polymer is also added. The invention also includes a process of extruding a composition of at least (a) and (b) to form a monofilament.

Owner:SK GEO CENTRIC CO LTD

High-obstruct multiple-layer film for packaging liquid and manufacturing method thereof

InactiveCN100560438CReduce consumptionReduce thicknessFlexible coversWrappersPolyesterMultilayer membrane

Disclosed is a high-barrier multilayer film for packaging liquid materials, comprising: one or more PE-based heat-sealing layers; one or more polymer barrier layers, preferably selected from ethylene-vinyl alcohol copolymer (EVOH ), polyvinyl alcohol (PVA) and vinylidene chloride (PVDC); and one or more layers selected from polypropylene (PP), polyester, silicone oil, silicone, polyester varnish, UV varnish, acrylate A protective layer of a compound, wherein the total thickness of the multilayer film may be less than 80 μm, preferably less than 70 μm, more preferably 55-65 μm. Also disclosed is a method for manufacturing the above-mentioned high-barrier multilayer film.

Owner:刘建林

Textured non-porous barrier transfer casing

ActiveUS20200037623A1Sufficient barrier effectPreventing contamination of environmentThermoplastic sausage casingsOrganic chemistryPolymer sciencePolyolefin

The present invention provides a functional additive transferring (co)extruded thermoplastic food casing having a water vapor barrier and / or oxygen barrier effect wherein an inside surface of the thermoplastic food casing has a textured surface which forms a three-dimensional pattern of higher and lower retaining capacity for a functional additive, wherein the thermoplastic food casing having a textured surface in case of a monolayer casing or an inner layer comprising the inside surface having a textured surface in case of a multilayer casing comprises as a main component at least one thermoplastic polymer material selected from the group consisting of (co)polyamides, (co)polyolefins, (co)polyester and vinylidenchloride (co)polymers, wherein the (co)extruded thermoplastic food casing does not comprise a net and / or a material forming a net or any other three dimensional structure on its outside surface, wherein the average thickness of the thermoplastic food casing in the areas having a higher retaining capacity is in a range of from 1 to 100 μm, wherein the average thickness of the thermoplastic food casing in the areas having a lower retaining capacity is in a range of from 191 to 2000 μm, provided that the thickness difference between the average thickness in the areas having higher retaining capacity and the average thickness in the areas having a lower retaining capacity is in a range of from 160 to 1950 μm and that a ratio of the average thickness of the thermoplastic food casing in the areas having a higher retaining capacity and the average thickness of the thermoplastic food casing in the areas having a lower retaining capacity is in a range of from 0.002 to 0.25.

Owner:VISCOFAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com