Hydrogen chloride resistant basic catalyst, preparation method and application

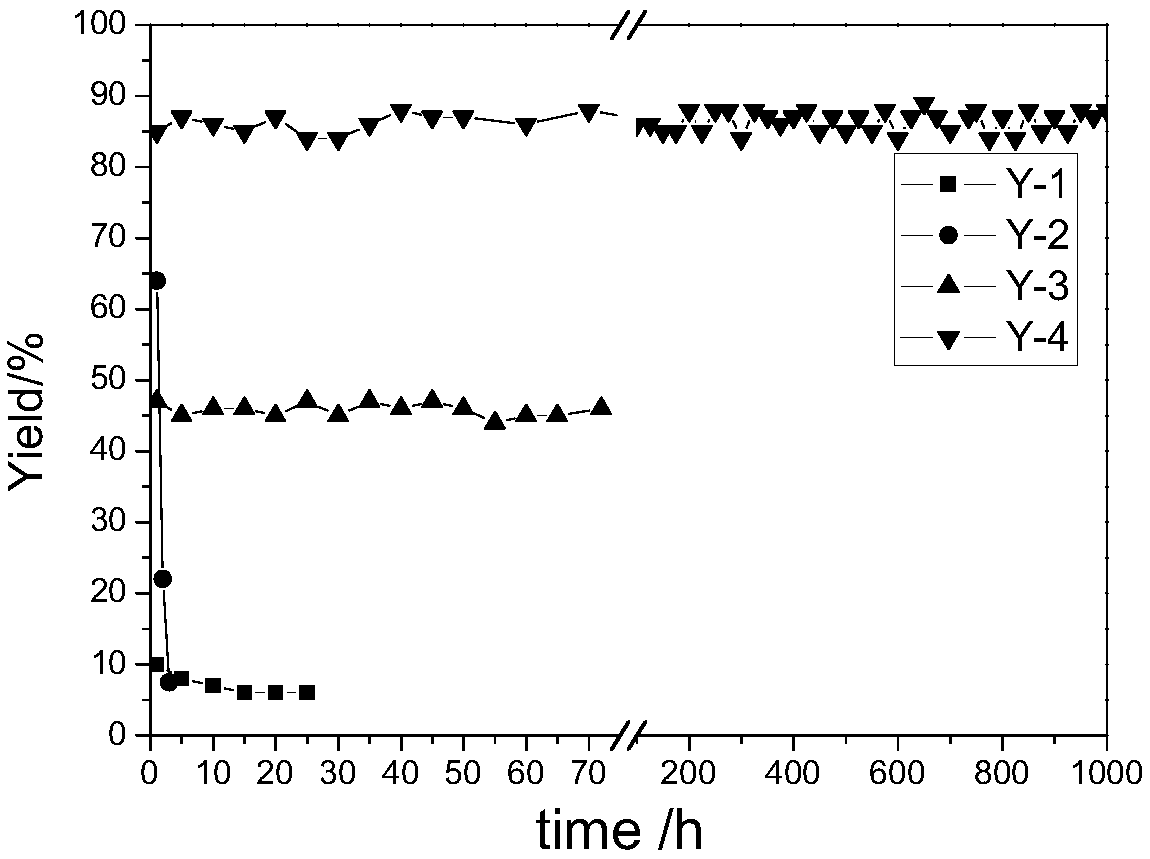

A catalyst and alkaline technology, which is applied in the field of hydrogen chloride-resistant alkaline catalyst and its preparation and application, and can solve the problems that gas-phase dehydrochlorination catalysts cannot meet the requirements of industrial production, low selectivity of vinylidene chloride, and short service life of catalysts, etc. , to achieve excellent resistance to hydrogen chloride, broad industrialization prospects, and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Dissolve the chloromethyltriphenylphosphorous chloride in absolute ethanol, the chloromethyltriphenylphosphorous chloride accounts for 1% of the mass of ethanol, and stir evenly with a stirring device.

[0046] (2) Use 0.1mol / L nitric acid to dissolve γ-Al 2 o 3 After soaking for 12 hours, soak the soaked γ-Al with deionized water 2 o 3 Wash to neutral. Washed γ-Al 2 o 3 Put it in a blast oven, dry at 200°C for 5 hours, and dry the γ-Al 2 o 3 Put it into a muffle furnace and bake at 800°C for 2 hours. The baked carrier is taken out for later use.

[0047] (3) The γ-Al obtained in (2) 2 o 3 Added to the solution of (1), γ-Al 2 o 3 Accounting for 10% of the mass of the solution, use a stirring device to stir evenly. Chloromethyltriphenylphosphonium chloride in γ-Al 2 o 3 The loading of the surface is 40%.

[0048] (4) Put the treated mixture in (3) in an ultrasonic cleaner for 4 hours. It was left to stand in an environment of 10° C. for 6 hours.

[...

Embodiment 2

[0052] (1) Dissolve tetraphenylphosphorus chloride in absolute ethanol, wherein tetraphenylphosphorus chloride accounts for 1% of the mass of absolute ethanol, and stir evenly with a stirring device.

[0053] (2) Use 4mol / L nitric acid to soak the activated carbon for 0.5 hour, and wash the soaked activated carbon to neutral with deionized water. The washed activated carbon was dried in a blast oven at 80°C for 10 hours, and the dried activated carbon was roasted in a tube furnace at 400°C under a nitrogen atmosphere for 12 hours, and the roasted carrier was taken out for use.

[0054] (3) Add the activated carbon obtained in (2) into the solution of (1), the activated carbon accounts for 25% of the solution mass, and use a stirring device to stir well. The loading of tetraphenylphosphine chloride on the surface of activated carbon is 4%.

[0055] (4) Put the treated mixture in (3) in an ultrasonic cleaning machine for 0.5 hours. It was left to stand in an environment of 40°...

Embodiment 3

[0059] (1) Dissolve trityltriphenylphosphorus chloride in absolute ethanol, wherein trityltriphenylphosphorus chloride accounts for 10% of the mass of absolute ethanol, and stir evenly with a stirring device.

[0060] (2) Use 4mol / L nitric acid to dissolve SiO 2 After soaking for 0.5 hours, the pickled SiO 2 Wash to neutral. Wash the SiO in a blast oven at 80°C 2 After drying for 5 hours, the dried SiO 2 Roast for 5 hours. The catalyst carrier that has been calcined is taken out for use.

[0061] (3) SiO obtained in (2) 2 Added to the solution of (1), SiO 2 Accounting for 60% of the solution mass, use a stirring device to stir evenly. Trityltriphenylphosphonium chloride on SiO 2 The load on it is 40%.

[0062] (4) Put the treated mixture in (3) in an ultrasonic cleaner for 4 hours. Post-processing is the same as (4) in embodiment 3.

[0063] (5) Dry the treated mixture in (4) for 24 hours in a blast oven at 80°C.

[0064] (6) The obtained catalyst is stored for fut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com