PVDC copolymer emulsion for wear-resistant water-based floor paint as well as preparation method and application thereof

A technology of copolymerization emulsion and floor paint, applied in the direction of coating, etc., can solve the problems of environmental and human health hazards, insufficient wear resistance, no flame retardancy, etc., and achieve good environmental protection, quality improvement, and good safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

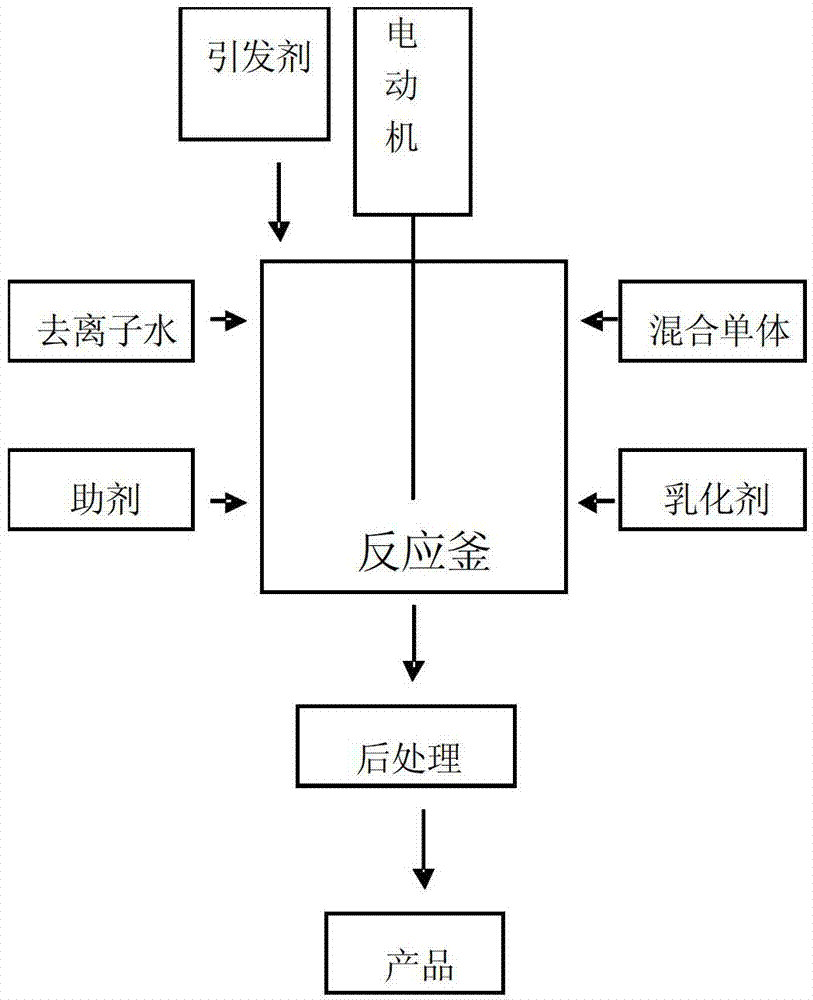

Method used

Image

Examples

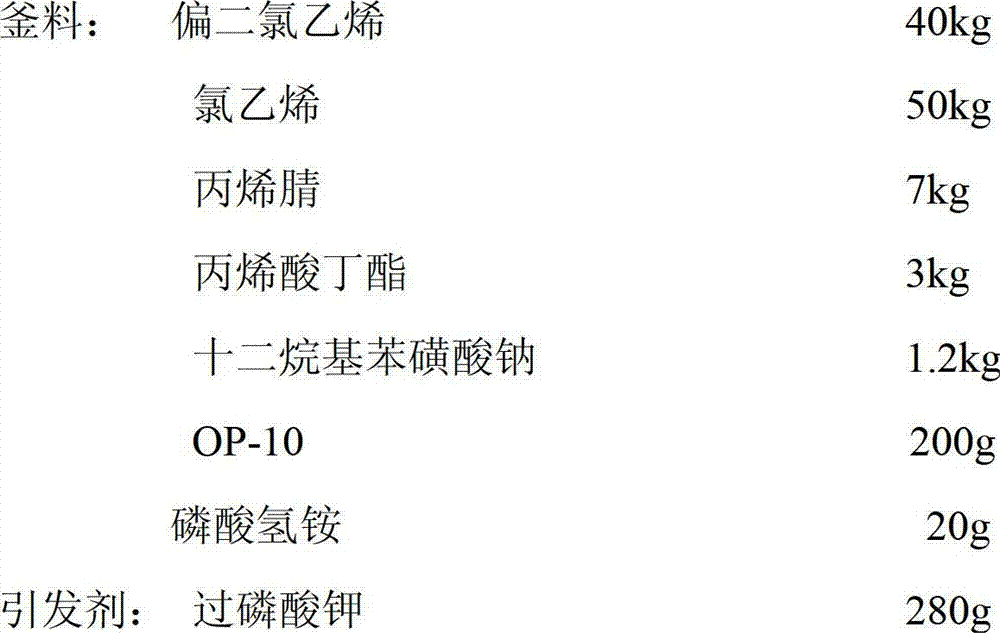

Embodiment 1

[0012]

[0013] The specific preparation process is: add 280g of potassium superphosphate to 8kg of water to obtain an aqueous solution of potassium superphosphate initiator; mix 80kg of water, 40kg of vinylidene chloride, 50kg of vinyl chloride, 7kg of acrylonitrile, 3kg of butyl acrylate, and dodecylbenzenesulfonate Add sodium phosphate 1.2kg, OP-10200g, and ammonium hydrogen phosphate 20g into the reactor and mix evenly, add potassium superphosphate initiator aqueous solution, when the reaction pressure drops to zero, the reaction ends, and adding potassium hydroxide to adjust the pH value is 2 to obtain PVDC copolymer emulsion with 50% solid content.

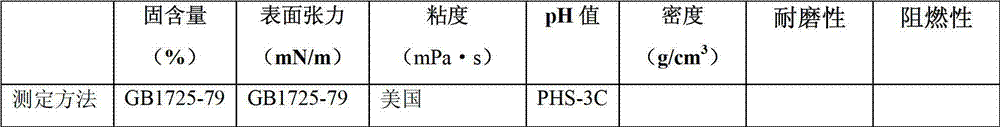

[0014] The physical index of the obtained wear-resistant water-based floor paint with PVDC copolymer emulsion is:

[0015]

[0016]

Embodiment 2

[0018]

[0019] The specific preparation process is: add 350g of potassium superphosphate to 8kg of water to obtain an aqueous solution of potassium superphosphate initiator; mix 60kg of water, 48kg of vinylidene chloride, 60kg of vinyl chloride, 8.4kg of acrylonitrile, 3.6kg of butyl acrylate, and Add 1.4kg of sodium benzenesulfonate, 300g of OP-10, and 20g of ammonium hydrogen phosphate into the reaction kettle and mix evenly, add an aqueous solution of potassium superphosphate initiator, when the reaction pressure drops to zero, the reaction ends, and then add potassium hydroxide to adjust the pH value to 2.2 , to obtain a PVDC copolymer emulsion with a solid content of 60%.

Embodiment 3

[0021]

[0022] The specific preparation process is: add 280g of potassium superphosphate to 8kg of water to obtain an aqueous solution of potassium superphosphate initiator; mix 80kg of water, 40kg of vinylidene chloride, 50kg of vinyl chloride, 7kg of acrylonitrile, 3kg of ethyl acrylate, and dodecylbenzenesulfonate Add 1.2kg of sodium phosphate, OP-4200g, and 20g of ammonium hydrogen phosphate into the reaction kettle and mix evenly, add potassium superphosphate initiator aqueous solution, when the reaction pressure drops to zero, the reaction ends, and adding triethylamine to adjust the pH value is 2 to obtain PVDC copolymer emulsion with 50% solid content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com